|

1

|

VERIFY FREEZE FRAME DATA (MODE 2)/SNAPSHOT DATA HAS BEEN RECORDED

• Has the FREEZE FRAME DATA (Mode 2)/snapshot data been recorded?

|

Yes

|

Go to the next step.

|

|

No

|

Record the FREEZE FRAME DATA (Mode 2)/snapshot data on the repair order, then go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY RELATED PENDING CODE AND/OR DTC

• Switch the ignition off, then ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Are any other PENDING CODEs and/or DTCs present?

|

Yes

|

Go to the applicable PENDING CODE or DTC inspection.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT EXHAUST SYSTEM FOR LEAKAGE

• Visually inspect for exhaust leakage in the exhaust system.

• Is there any leakage?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

5

|

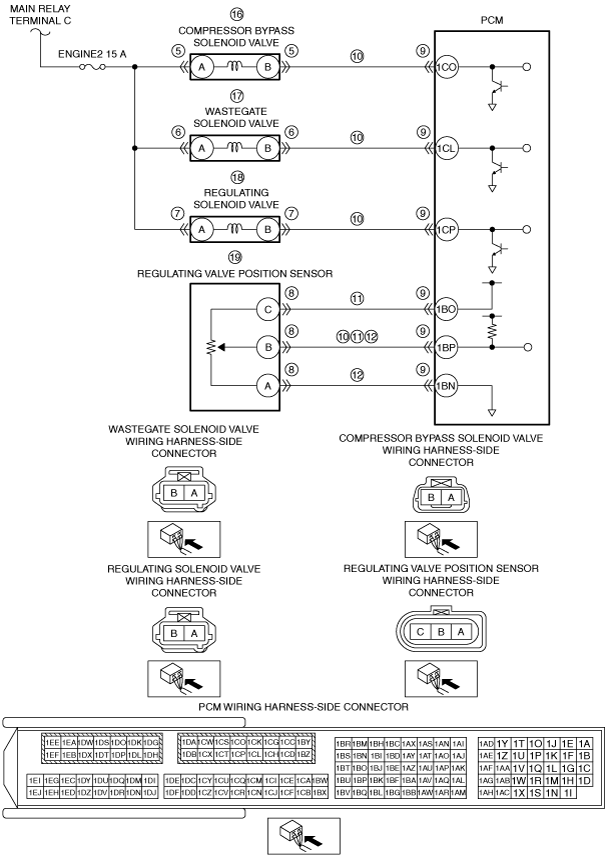

INSPECT COMPRESSOR BYPASS SOLENOID VALVE CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the compressor bypass solenoid valve connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

6

|

INSPECT WASTEGATE SOLENOID VALVE CONNECTOR CONDITION

• Disconnect the wastegate solenoid valve connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

7

|

INSPECT REGULATING SOLENOID VALVE CONNECTOR CONDITION

• Disconnect the regulating solenoid valve connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

8

|

INSPECT REGULATING VALVE POSITION SENSOR CONNECTOR CONDITION

• Disconnect the regulating valve position sensor connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

9

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT EACH CIRCUIT FOR SHORT TO POWER SUPPLY

• Verify that the compressor bypass solenoid valve and wastegate solenoid valve and regulating solenoid valve and regulating valve position sensor and PCM connectors are disconnected.

• Switch the ignition ON (engine off).

• Measure the voltage at the following terminals (wiring harness-side):

-

― Compressor bypass solenoid valve terminal B

― Wastegate solenoid valve terminal B

― Regulating solenoid valve terminal B

― Regulating valve position sensor terminal B

• Is the voltage B+?

|

Yes

|

Repair or replace the wiring harness for a possible short to power supply, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

11

|

INSPECT REGULATING VALVE POSITION SENSOR POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT FOR SHORT TO EACH OTHER

• Verify that the compressor bypass solenoid valve and wastegate solenoid valve and regulating solenoid valve and regulating valve position sensor and PCM connectors are disconnected.

• Switch the ignition off.

• Inspect for continuity between regulating valve position sensor terminals C and B (wiring harness-side).

• Is there continuity?

|

Yes

|

Repair or replace the wiring harness for a possible short to each other, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

12

|

INSPECT REGULATING VALVE POSITION SENSOR CIRCUIT FOR OPEN CIRCUIT

• Verify that the compressor bypass solenoid valve and wastegate solenoid valve and regulating solenoid valve and regulating valve position sensor and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

-

― Regulating valve position sensor terminal B—PCM terminal 1BP

― Regulating valve position sensor terminal A—PCM terminal 1BN

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or the replace the wiring harness for a possible open circuit, then go to Step 21.

|

|

13

|

INSPECT VACUUM PIPING AND POSITIVE PRESSURE PIPING OF COMPRESSOR BYPASS VALVE

• Inspect vacuum piping and positive pressure piping of compressor bypass valve.

• Is there hose leakage or damage in the vacuum piping and positive pressure piping?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

14

|

INSPECT VACUUM PIPING AND POSITIVE PRESSURE PIPING OF WASTEGATE VALVE

• Inspect vacuum piping and positive pressure piping of wastegate valve.

• Is there hose leakage or damage in the vacuum piping and positive pressure piping?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

15

|

INSPECT VACUUM PIPING AND POSITIVE PRESSURE PIPING OF REGULATING VALVE

• Inspect vacuum piping and positive pressure piping of regulating valve.

• Is there hose leakage or damage in the vacuum piping and positive pressure piping?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

16

|

INSPECT COMPRESSOR BYPASS SOLENOID VALVE

• Inspect the compressor bypass solenoid valve.

• Is there any malfunction?

|

Yes

|

Replace the compressor bypass solenoid valve, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

17

|

INSPECT WASTEGATE SOLENOID VALVE

• Inspect the wastegate solenoid valve.

• Is there any malfunction?

|

Yes

|

Replace the wastegate solenoid valve, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

18

|

INSPECT REGULATING SOLENOID VALVE

• Inspect the regulating solenoid valve.

• Is there any malfunction?

|

Yes

|

Replace the regulating solenoid valve, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

19

|

INSPECT REGULATING VALVE POSITION SENSOR

• Reconnect all disconnected connectors.

• Inspect the regulating valve position sensor.

• Is there any malfunction?

|

Yes

|

Replace the regulating valve actuator, then go to Step 21.

|

|

No

|

Go to the next step.

|

|

20

|

INSPECT TURBOCHARGER

• Inspect the turbocharger.

• Is there any malfunction?

|

Yes

|

Replace the turbocharger, then go to the next step.

|

|

No

|

Go to the next step.

|

|

21

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Start the engine and warm it up completely.

-

Caution

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

• Drive the vehicle under the FREEZE FRAME DATA (Mode 2)/snapshot data condition.

• Perform the Pending Trouble Code Access Procedure.

• Is the PENDING CODE for this DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

22

|

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|