STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN RECORDED

• Has FREEZE FRAME DATA been recorded?

Yes

Go to the next step.

No

Record FREEZE FRAME DATA on the repair order, then go to the next step.

2

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

Yes

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

3

VERIFY RELATED PENDING CODE OR STORED DTCS

• Turn the ignition switch off, then to the ON position (engine off).

• Verify related PENDING CODE or stored DTCs.

• Are any DTCs present other than the following:

-

― P0172:00, P0175:00, P2196:00 or P2198:00?

Yes

Go to the appropriate DTC troubleshooting procedures.

No

Go to the next step.

4

VERIFY FUEL AND ENGINE OIL CONDITIONS

-

Note

-

• An engine that consumes oil at a high rate deposits high levels of phosphorus on the catalyst and reduces the catalyst efficiency.

• Make sure the customer has not:

-

― Noticed a high vehicle oil consumption.

• Does the vehicle exhibit any of the above condition?

Yes

Replace the engine oil.

Go to the next step.

No

Go to the next step.

5

INSPECT ENTIRE INTAKE AIR SYSTEM FOR DEBRIS, BLOCKAGE OR OTHER DAMAGE

• Check the intake air system for obstructions, restrictions, and damage.

• Check the throttle plate for obstructions or sludge.

• Check the air filter element and housing for blockage.

• Is a concern present?

Yes

Repair if necessary.

Then go to Step 24.

No

Go to the next step.

6

INSPECT FUEL PRESSURE

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death. Fuel can also irritate skin and eyes. To prevent this, always complete the “BEFORE REPAIR PROCEDURE”.

-

Note

-

• For vehicle specific fuel pressure ranges, refer to the “FUEL LINE PRESSURE INSPECTION”.

• Remove the jumper wire(s).

• Connect the A/F sensor connector.

• Relieve the fuel pressure.

• Connect the mechanical fuel pressure gauge

• Pressurize the fuel system.

• Turn the ignition switch to the ON position (engine running).

• Allow the fuel pressure to stabilize.

• Turn the ignition switch off.

• Turn the ignition switch to the ON position (engine running).

• Measure the fuel pressure.

• Is the fuel pressure within the range for the vehicle being diagnosed?

Yes

Go to Step 16.

No

Go to the next step.

7

INSPECT FUEL LINE PRESSURE

• Turn the ignition switch off.

• Connect the mechanical fuel pressure gauge.

• Connect the FP connector.

• Turn the ignition switch to the ON position (engine off).

• Pressurize the fuel system.

• Cycle the key several times to charge the fuel system.

• Relieve the fuel pressure.

• Is the fuel pressure within range?

Yes

Go to Step 8.

No

Go to the next step.

8

INSPECT FUEL PUMP GROUND CIRCUIT FOR OPEN CIRCUIT IN WIRING HARNESS

-

Note

-

• Refer to the Wiring Diagrams Manual for schematic and connector information.

• Turn the ignition switch off.

• Disconnect the FP and fuel pump relay connectors.

• Verify that continuity between FP (wiring harness-side connector) terminal D and ground.

• Is there any continuity?

Yes

Go to the next step.

No

Repair for an open circuit, then go to Step 24.

9

INSPECT FUEL PUMP POWER CIRCUIT FOR OPEN CIRCUIT IN WIRING AN HARNESS

-

Note

-

• Refer to the Wiring Diagrams Manual for schematic and connector information.

• Turn the ignition switch off.

• Disconnect the FP and fuel pump relay connectors.

• Verify that continuity between FP (wiring harness-side connector) terminal B and fuel pump relay (wiring harness-side connector) terminal C.

• Is there any continuity?

Yes

Go to Step 12.

No

Repair for an open circuit, then go to Step 24.

10

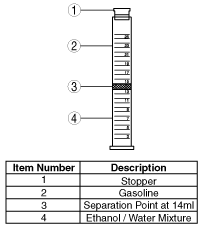

CALCULATE PERCENTAGE OF ETHANOL IN FUEL

-

Note

-

• Use the illustration as an example for calculating the percentage of ethanol using the following steps. If the separation level is at 14 ml, the calculation is; 14 minus 4, then multiply by 5 to equal 50. The percentage of ethanol in the fuel is 50%

am6xuw00002542

am6xuw00002542

• Turn the ignition switch off.

• Take the recorded separation level from the previous step and subtract the amount of water added

• Multiply the new value by 5. This new value is the percentage of ethanol in the fuel

• Record the calculated percentage of ethanol in the fuel

• Is any ethanol present in the fuel?

Yes

Go to the next step.

No

Go to Step 12.

11

DETERMINE IF PERCENTAGE OF ETHANOL IN FUEL IS LESS THAN 10%

• Verify the recorded calculated percentage of ethanol in the fuel.

• Is the calculated percentage of ethanol in the fuel less than 10%?

Yes

Go to the next step.

No

Replace the fuel.

Advice the customer of the correct fuel type required for this vehicle. Refer to the Owner's Manual Literature for additional information.

Go to Step 24.

12

INSPECT FUEL PRESSURE DECREASE

• Connect the mechanical fuel pressure gauge.

• Turn the ignition switch to the ON position (engine running).

• Allow the fuel pressure to stabilize.

• Record the stabilized reading.

• Turn the ignition switch off.

• Monitor the fuel pressure for 1 min.

• Does the fuel pressure remain within 34 kPa {255 mmHg, 10.0 inHg} of the recorded reading after 1 min?

Yes

Go to Step 14.

No

Go to the next step.

13

INSPECT FUEL INJECTOR FOR FLOW AND LEAKAGE

-

Note

-

• Observe the Warnings, Cautions, and Notes.

• Inspect the fuel injectors for leakage and flow rate using the injector flow tester or other method such as inspecting the intake manifold for fuel.

• Are the test results satisfactory?

Yes

Go to the next step.

No

Replace the suspect fuel injector, then go to Step 24.

14

MONITOR FUEL PRESSURE WHILE ROAD TESTING VEHICLE

-

Warning

-

• Strict observance of posted speed limits and attention to driving conditions are mandatory when performing the road test. Failure to follow these instructions may result in personal injury.

-

Note

-

• Some concerns may only be present during certain fuel level conditions. Determine the fuel level at the time of the concern. Access the information from the customer information worksheet and the customer.

• Turn the ignition switch off.

• Securely route the mechanical gauge so that the gauge is viewable while road testing the vehicle.

• Start the engine and run it at idle.

• Warm up the engine to normal operating temperature.

• Monitor the mechanical gauge.

• From a stop, accelerate to 89 km/h (55 mph) at full throttle.

• Repeat 3 times.

• Is the fuel pressure always greater than 240 kPa {2.45 kgf/cm2, 34.8 psi}?

Yes

Unable to duplicate or identify the concern at this time.

Go to Step 24.

No

Go to the next step.

15

INSPECT FUEL SUPPLY LINE FOR RESTRICTION

-

Note

-

• Observe the Warnings, Cautions, and Notes.

• Turn the ignition switch off.

• Disconnect the fuel supply line at the fuel rail.

• Disconnect the fuel supply line at the fuel pump.

• Verify the fuel supply line for restriction.

• Apply 21—34 kPa {0.22—0.34 kgf/cm2, 3.1—4.9 psi} air pressure to the fuel supply line.

• Does air flow freely through the line?

Yes

Replace the fuel filter (low-pressure side).

Go to the next step.

No

Repair the cause of the restriction, then go to Step 24.

16

VERIFY FUEL SYSTEM IS REPAIRED

-

Warning

-

• Strict observance of posted speed limits and attention to driving conditions are mandatory when performing the road test. Failure to follow these instructions may result in personal injury.

• Start the engine and run it at idle.

• Warm up the engine to normal operating temperature.

• Monitor the mechanical gauge.

• From a stop, accelerate to 89 km/h (55 mph) at full throttle.

• Repeat 3 times.

• Is the fuel pressure always greater than 240 kPa {2.45 kgf/cm2, 34.8 psi}?

Yes

The test is complete and no concerns are present.

Go to Step 24.

No

Replace the fuel pump unit, then go to Step 24.

17

VERIFY FUEL SYSTEM FOR PRESSURE STABILITY-FAST DECREASE

• Mechanical fuel pressure gauge connected.

• Turn the ignition switch to the ON position (engine running).

• Allow the fuel pressure to stabilize

• Record the stabilized reading

• Turn the ignition switch off.

• Monitor the fuel pressure for 10 s.

• Measure the fuel line pressure after 10 s.

• Does the fuel pressure remain within 34 kPa {0.35 kgf/cm2, 4.9 psi} of the recorded reading after 10 s?

Yes

Go to Step 19.

No

Go to the next step.

18

INSPECT FOR EXTERNAL FUEL LEAK

• Inspect the fuel tank, lines, and filler pipe for a fuel leak.

• Is a concern present?

Yes

Repair for fuel leakage, then go to Step 24.

No

Go to Step 21.

19

VERIFY FUEL SYSTEM FOR PRESSURE STABILITY - SLOW DECREASE

• Continue to monitor the fuel pressure for 1 min.

• Does the fuel pressure remain within 34 kPa {0.35 kgf/cm2, 4.9 psi} of the recorded reading after 1 min?

Yes

Go to the next step.

No

Go to Step 13.

20

DETERMINE IF THE PERCENTAGE OF ETHANOL IN THE FUEL IS LESS THAN 10%

• Check the recorded (calculated) percentage of ethanol in the fuel referring to Step 10 and 11.

• Is the calculated percentage of ethanol in the fuel less than 10%?

Yes

Go to the next step.

No

Replace the fuel.

Advice the customer of the correct fuel type required for this vehicle. Refer to the Owner's Manual Literature for additional information.

Go to Step 24.

21

INSPECT FUEL INJECTOR OPERATION

• Perform the “Fuel Injector Operation Inspection” for the right bank (with DTC P0172:00) or the left bank (with DTC P0175:00).

• Does the fuel injector operate properly?

Yes

Go to the next step.

No

Replace the suspect fuel injector.

Then go to Step 24.

22

VERIFY FUNCTIONALITY OF MAF SENSOR

-

Note

-

• MAF PID value of less than 0.6 V may indicate an incorrectly installed air cleaner or a leak in the intake-air system.

• Start the engine and run it at idle.

• Allow the engine to stabilize at the correct operating temperature.

• Access and monitor the MAF PID.

• Inspect that the MAF PID at idle and P/N position is not greater than 30% of the normal MAF listed. Reference Values are not greater than 1.3 V.

(See PCM INSPECTION [MZI-3.7].)

• Is the PID value within the expected range?

Yes

Unable to duplicate or identify the concern at this time.

Go to Step 24.

No

Go to the next step.

23

INSPECT TO ISOLATE MAF SENSOR FROM LEAN DRIVEABILITY OCCURRENCE

-

Note

-

• Due to increasingly stringent emission/OBD requirements, a fuel system DTC on some vehicles can be generated without a noticeable drivability concern with or without the MAF sensor disconnected. Under these conditions, if the MAF PID indicates a MAF sensor concern, replace the MAF sensor.

• Turn the ignition switch off.

• Disconnect the MAF/IAT sensor connector.

• Start the engine and run it at idle.

• Drive the vehicle on the road.

• Does the lean drivability symptom (lack of power, spark knock/detonation, buck/jerk or hesitation/surge on acceleration) disappear?

Yes

Replace the MAF/IAT sensor, then go to the next step.

No

Go to the next step.

(The system is correctly at this time. The concern may have been caused by a loose or corroded connector.)

24

VERIFY TROUBLESHOOTING OF DTC P0172:00, P0175:00 HAS BEEN COMPLETED

• Verify that all disconnected connectors are reconnected.

• Clear the DTC from the PCM memory using the M-MDS.

• Perform the OBD DRIVE MODE up to Misfire, Fuel and HO2S Monitors (Step 11).

• Retrieve DTCs using the M-MDS.

• Is the PENDING CODE for this DTC present?

Yes

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

No

Go to the next step.

25

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

Yes

Go to the applicable DTC inspection.

No

Troubleshooting completed.