DTC

U0001:88

Module communication error

U0073

CAN system communication error

U0073:00

CAN system communication error

DETECTION CONDITION

-

Warning

-

• Perform the following on-board diagnosis according to FOREWORD [MULTIPLEX COMMUNICATION SYSTEM (R.H.D.)] troubleshooting procedure.

• CAN system-related harness malfunction

• CAN system-related module malfunction

POSSIBLE CAUSE

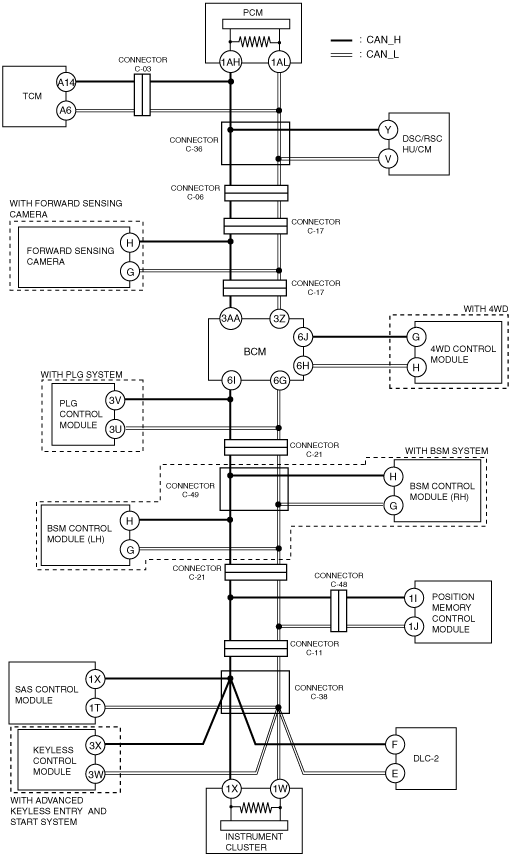

• Open or short circuit in wiring harness

• Malfunction of connectors between PCM, TCM, DSC/RSC HU/CM, forward sensing camera, BCM, 4WD control module, PLG control module, BSM control module (LH), BSM control module (RH), position memory control module, SAS control module, keyless control module and instrument cluster

• PCM malfunction

• TCM malfunction

• DSC/RSC HU/CM malfunction

• Forward sensing camera malfunction

• BCM malfunction

• 4WD control module malfunction

• PLG control module malfunction

• BSM control module (LH) malfunction

• BSM control module (RH) malfunction

• Position memory control module malfunction

• SAS control module malfunction

• Keyless control module malfunction

• Instrument cluster malfunction