Description

Any of the following lights turn on. (ABS warning light, TCS/DSC operation indicator light, or TCS OFF indicator light)

Possible cause

• Electronically controlled brake unit detects malfunction (input/output device malfunction)

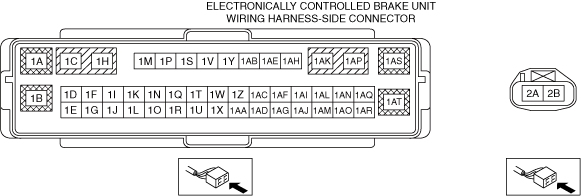

• Electronically controlled brake unit connector is disconnected (circuit that turns on ABS warning light, TCS/DSC operation indicator light, brake system warning light, and TCS OFF indicator light if electronically controlled brake unit connector is disconnected)

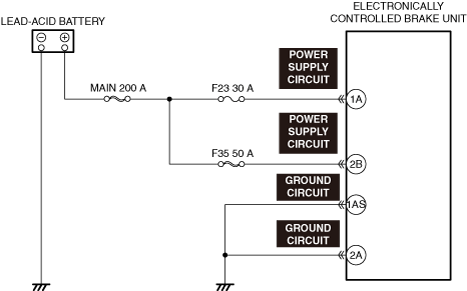

• Electronically controlled brake unit power supply voltage decreases

• Poor ground in electronically controlled brake unit (If electronically controlled brake unit ground is not secured properly, ABS warning light, TCS/DSC operation indicator light, brake warning light, and TCS OFF indicator light turn on, but no DTC is output)

• Electronically controlled brake unit does not activate

• PCM detects malfunction

• Error signal received from PCM

• Body control module (BCM) detects malfunction

• Communication error between electronically controlled brake unit and PCM

• Communication error between electronically controlled brake unit and EPS control module

• Communication error between electronically controlled brake unit and body control module (BCM)

• Communication error between electronically controlled brake unit and Sophisticated Airbag Sensor (SAS) control module

• Communication error between body control module (BCM) and instrument cluster

• After replacing Sophisticated Airbag Sensor (SAS) control module, sensor initialization procedure for electronically controlled brake unit related parts not performed

• After replacing electronically controlled brake unit, initialization procedure for brake fluid pressure sensor not performed

• When replacing electronically controlled brake unit, configuration not performed (if configuration for electronically controlled brake unit is not performed, ABS warning light turns on)

• Electronically controlled brake unit internal malfunction

• Instrument cluster malfunction