|

1

|

VERIFY FREEZE FRAME DATA (MODE 12) HAS BEEN RECORDED

• Has the FREEZE FRAME DATA (Mode 12) been recorded?

|

Yes

|

Go to the next step.

|

|

No

|

Record the FREEZE FRAME DATA (Mode 12) on the repair order, then go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT CMP SENSOR CONNECTOR AND TERMINALS

• Turn the ignition switch off.

• Disconnect the CMP sensor connector.

• Inspect for poor connection (such as damaged/pulled-out pins, and corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector or terminals, then go to Step 14.

|

|

No

|

Go to the next step.

|

|

4

|

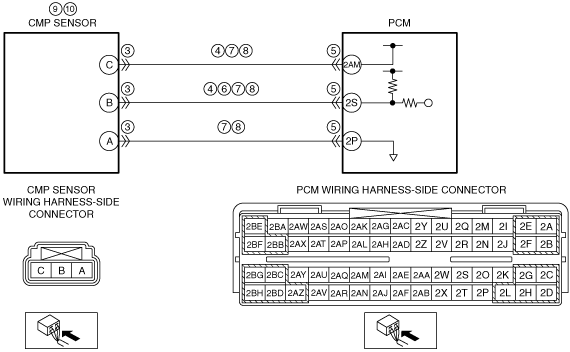

INSPECT CMP SENSOR CIRCUIT FOR SHORT TO GROUND

• CMP sensor connector is disconnected.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

-

― CMP sensor terminal C

― CMP sensor terminal B

• Is there continuity?

|

Yes

|

If the short to ground circuit could be detected:

• Repair or replace the wiring harness for a possible short to ground.

If the short to ground circuit could not be detected:

• Replace the PCM (short to ground in PCM internal circuit).

Go to Step 14.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT PCM CONNECTOR AND TERMINALS

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, and corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector or terminals, then go to Step 14.

|

|

No

|

Go to the next step.

|

|

6

|

INSPECT CMP SENSOR CIRCUIT FOR SHORT TO POWER SUPPLY

• CMP sensor and PCM connectors are disconnected.

• Turn ignition switch to the ON position (engine off).

• Measure the voltage between CMP sensor terminal B (wiring harness-side) and body ground.

• Is there any voltage?

|

Yes

|

Repair or replace the wiring harness for a possible short to power supply, then go to Step 14.

|

|

No

|

Go to the next step.

|

|

7

|

INSPECT CMP SENSOR CIRCUITS FOR SHORT TO EACH OTHER

• CMP sensor and PCM connectors are disconnected.

• Turn the ignition switch off.

• Inspect for continuity between CMP sensor terminals C, B and A (wiring harness-side).

• Is there continuity?

|

Yes

|

Repair or replace the suspected wiring harness, then go to Step 14.

|

|

No

|

Go to the next step.

|

|

8

|

INSPECT CMP SENSOR CIRCUIT FOR OPEN CIRCUIT

• CMP sensor and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

-

― CMP sensor terminal C and PCM terminal 2AM

― CMP sensor terminal B and PCM terminal 2S

― CMP sensor terminal A and PCM terminal 2P

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness for a possible open circuit, then go to Step 14.

|

|

9

|

INSPECT CMP SENSOR

• Turn the ignition switch off.

• Inspect the CMP sensor.

• Is there any malfunction?

|

Yes

|

Replace the CMP sensor and go to Step 14.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT INSTALLATION OF CMP SENSOR

• Inspect if the CMP sensor is loosely installed

• Is the CMP sensor installed correctly?

|

Yes

|

Go to the next step.

|

|

No

|

Retighten the CMP sensor, then go to Step 14.

|

|

11

|

VERIFY VALVE TIMING MECHANISM INSTALLATION

• Verify the valve timing mechanism installation for the following parts:

-

― Timing chain misinstallation

― Loose camshaft sprocket lock bolt

― Loose crankshaft pulley lock bolt

• Is the valve timing mechanism installed correctly?

|

Yes

|

Go to the next step.

|

|

No

|

Reinstall the following parts, then go to Step 14.

• Timing chain

• Camshaft sprocket

• Crankshaft pulley

|

|

12

|

INSPECT STOPPER PIN MECHANISM

• Remove the timing chain.

• Inspect the stopper pin.

• Is the stopper pin mechanism normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the variable valve timing actuator, then go to Step 14.

|

|

13

|

INSPECT ROTOR POSITION

• Remove the variable valve timing actuator.

• Is the rotor at the maximum valve timing advanced position?

|

Yes

|

Replace the variable valve timing actuator, then go to the next step.

|

|

No

|

Variable valve timing mechanism is normal.

-

Note

-

• This DTC is detected as an intermittent concern.

• The intermittent concern might be removed by cleaning the variable valve timing mode control function.

Go to the next step.

|

|

14

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Make sure to reconnect all disconnected connectors.

• Turn ignition switch to the ON position (engine off).

• Clear the DTC from the PCM memory using the M-MDS.

• Start the engine and warm it up completely.

• Perform the PID/DATA Monitor and Record Procedure and access the MAF PID.

-

Note

-

• The MAF PID should indicate 1.95 g/s {0.25 lb/min} or above during this test.

• Perform the DTC Reading Procedure.

• Is the same DTC present?

|

Yes

|

Replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

15

|

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|