|

1

|

VERIFY THAT OPERATION INDICATOR LIGHT TURNS ON WHEN REMOTE TRANSMITTER BUTTON IS USED

• Does the operation indicator light turn on?

|

Yes

|

Go to Step 4.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY IF PROBLEM IS DUE TO REMOTE TRANSMITTER POWER SAVING FUNCTION

• Turn off the power saving function.

• Does the operation indicator light turn on?

|

Yes

|

Perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY BATTERY USED FOR REMOTE TRANSMITTER

• Is any of the following conditions met?

-

― Battery other than CR2025 is used (With remote transmitter type A)

― Battery other than CR2032 is used (With remote transmitter type B)

― Battery is inserted in opposite direction

― Battery voltage is low

|

Yes

|

Replace the remote transmitter battery and perform the repair completion verification.

|

|

No

|

Replace the remote transmitter and perform the repair completion verification.

|

|

4

|

DETERMINE IF MALFUNCTION CAUSE IS DOOR/ FUEL-FILLER LID LOCK

• Refer to “door lock does not operate” or “fuel-filler lid lock does not operate” symptom troubleshooting and perform the inspection.

• Is the advanced keyless entry system operating normally?

|

Yes

|

Troubleshooting completed.

(Explain the contents of the servicing to the customer.)

|

|

No

|

Go to the next step.

|

|

5

|

VERIFY IF MALFUNCTION CAUSE IS OPERATION OTHER THAN OPERATION PERMISSION CONDITION

• Verify the advanced keyless operation by operating each request switch and the trunk lid opener switch with all the following conditions met.

-

― All doors and trunk lid closed

― Ignition switched off

― Remote transmitter is within reception area (80 cm radius from driver's door, passenger's door, and trunk lid)

• Is the advanced keyless entry system operating normally?

|

Yes

|

System is normal.

(Explain to customer about operation range of advanced keyless entry system)

|

|

No

|

Go to the next step.

|

|

6

|

VERIFY IF MALFUNCTION CAUSE IS EXTRINSIC NOISE

• Ask the customer malfunction condition.

• Does the malfunction occur at the specified place where extrinsic noise is received such as a TV tower, electric power station, or a broadcast station?

|

Yes

|

System is normal.

(Explain the customer that operation cannot be performed caused by extrinsic noise.)

|

|

No

|

Go to the next step.

|

|

7

|

VERIFY MALFUNCTION SYMPTOM

• Does the trunk lid open using the trunk lid opener switch operation?

|

Yes

|

Go to Step 10.

(The trunk lid latch system is normal.)

|

|

No

|

Go to the next step.

|

|

8

|

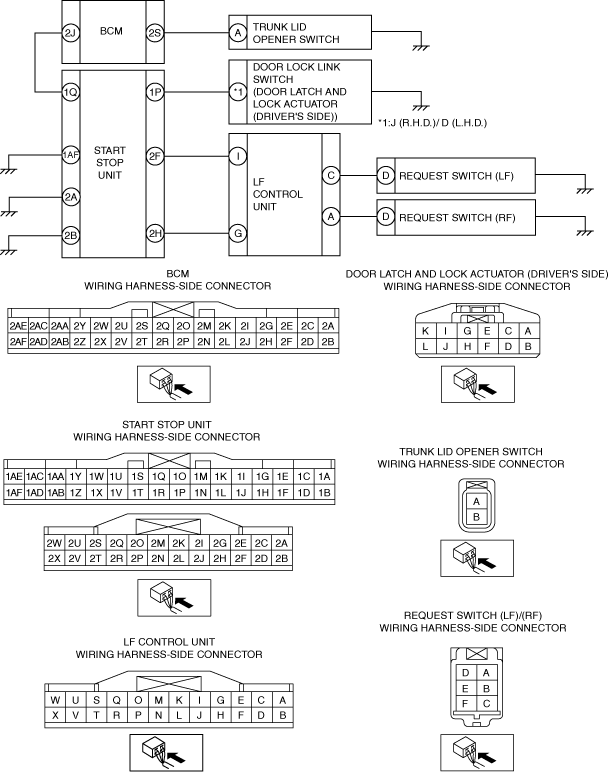

INSPECT TRUNK LID OPENER SWITCH-RELATED WIRING HARNESS (OPEN CIRCUIT)

• Disconnect the negative battery terminal.

• Disconnect the BCM and trunk lid opener switch connector.

• Inspect for continuity between the following terminals (vehicle wiring harness).

-

― Trunk lid opener switch terminal A and BCM terminal 2S

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

• Refer to the wiring diagram and verify if there is a common connector between the following terminals.

-

― Trunk lid opener switch terminal A and BCM terminal 2S

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

• Go to Step 15.

|

|

9

|

INSPECT TRUNK LID OPENER SWITCH

• Inspect the trunk lid opener switch.

• Is the trunk lid opener switch normal?

|

Yes

|

-

Note

-

• A trunk lid release actuator or trunk lid latch switch malfunction can be considered.

Replace the trunk lid latch and release actuator, then go to Step 15.

|

|

No

|

Replace the trunk lid opener switch, then go to Step 15.

|

|

10

|

VERIFY MALFUNCTION SYMPTOM

• Connect the negative battery terminal.

• Verify the lock/unlock operation for all doors, fuel-filler lid and trunk lid using the request switch operation.

• Is door or fuel-filler lid or trunk lid locked/unlocked?

|

Yes

|

Go to Step 15.

|

|

No

|

Go to the next step.

|

|

11

|

INSPECT DOOR LOCK LINK SWITCH-RELATED WIRING HARNESS (OPEN CIRCUIT)

• Disconnect the negative battery terminal.

• Disconnect the start stop unit and the door latch and lock actuator (driver's side) connector.

• Inspect for continuity between the following terminals (vehicle wiring harness).

-

― Start stop unit terminal 1P and door lock link switch terminal J (R.H.D.)/ D (L.H.D.)

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

• Refer to the wiring diagram and verify if there is a common connector between the following terminals.

-

― Start stop unit terminal 1P and door lock link switch terminal J (R.H.D.)/ D (L.H.D.)

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

• Go to Step 15.

|

|

12

|

INSPECT DOOR LOCK LINK SWITCH-RELATED WIRING HARNESS (SHORT TO GROUND)

• Verify that the start stop unit connector is disconnected.

• Inspect for continuity between the following wiring harness terminals (vehicle wiring harness side) and body ground.

-

― Start stop unit terminal 1P

• Is there continuity?

|

Yes

|

• Refer to the wiring diagram and verify if there is a common connector between the following terminals.

-

― Start stop unit terminal 1P and door lock link switch terminal J (R.H.D.)/ D (L.H.D.)

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an short to ground to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which has an short to ground.

• Go to Step 15.

|

|

No

|

Go to the next step.

|

|

13

|

INSPECT START STOP UNIT RELATED WIRING HARNESS (OPEN CIRCUIT)

• Verify that the start stop unit connector is disconnected.

• Inspect for continuity between the following terminals (vehicle wiring harness).

-

― Start stop unit terminal 1AF and ground

― Start stop unit terminal 2A and ground

― Start stop unit terminal 2B and ground

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

• Refer to the wiring diagram and verify if there is a common connector between the following terminals.

-

― Start stop unit terminal 1AF and ground

― Start stop unit terminal 2A and ground

― Start stop unit terminal 2B and ground

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

• Go to Step 15.

|

|

14

|

INSPECT REQUEST SWITCH RELATED WIRING HARNESS (OPEN CIRCUIT)

• Disconnect the LF control unit and request switch connector.

• Inspect for continuity between the following terminals (vehicle wiring harness).

-

― Request switch (RF) terminal D and LF control unit terminal A

― Request switch (LF) terminal D and LF control unit terminal C

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

• Refer to the wiring diagram and verify if there is a common connector between the following terminals.

-

― Request switch (RF) terminal D and LF control unit terminal A

― Request switch (LF) terminal D and LF control unit terminal C

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

• Go to the next step.

|

|

15

|

VERIFY IF MALFUNCTION CAUSE WAS CORRECTED

• Does the advanced keyless entry system operate normally?

|

Yes

|

Troubleshooting completed.

(Explain the contents of the servicing to the customer.)

|

|

No

|

If the malfunction has not been resolved, repeat the inspection from Step 1.

|