|

1

|

DETERMINE IF MALFUNCTION CAUSED BY AT BODY

• Compare the malfunction symptom with the i-stop system stop condition.

• Is there any shock or slippage during acceleration with the i-stop system disabled?

|

Yes

|

Perform the applicable symptom troubleshooting procedure.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY DTC

• Retrieve the PCM, TCM, DSC HU/CM, SAS control module DTCs using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

3

|

DETERMINE IF MALFUNCTION CAUSE IS BRAKE FLUID PRESSURE SENSOR SIGNAL OR OTHER

• Put the vehicle in an i-stop condition (engine stopped).

• Monitor the PCM PID BFP using the M-MDS while the brake is depressed and held with the i-stop function operating.

• Does the monitoring value change?

|

Yes

|

Brake fluid pressure sensor (built-into DSC HU/CM) or DSC HU/CM brake pressure hold function malfunction.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT ELECTRIC AT OIL PUMP RELAY

• Switch the ignition off.

• Remove the electric AT oil pump relay.

• Inspect the electric AT oil pump relay.

• Is there any malfunction?

|

Yes

|

Replace the electric AT oil pump relay.

|

|

No

|

Vehicles with i-ELOOP:

• Go to Step 7.

Vehicles without i-ELOOP:

• Go to the next step.

|

|

5

|

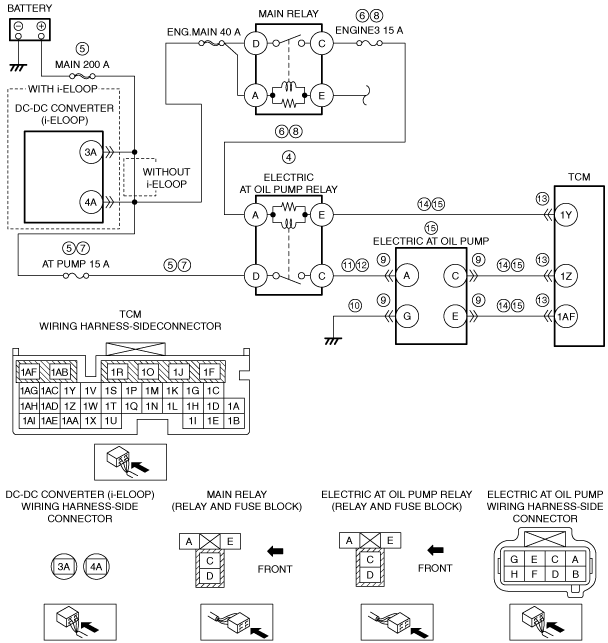

INSPECT ELECTRIC AT OIL PUMP RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Electric AT oil pump relay is removed.

• Measure the voltage at the electric AT oil pump relay terminal D (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the MAIN 200 A fuse and AT PUMP 15 A fuse.

• If the fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between MAIN 200 A fuse and electric AT oil pump relay terminal D.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a short to ground.

• Replace the malfunctioning fuse.

• If the fuse is damaged:

-

― Replace the malfunctioning fuse.

• If all fuses are normal:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between battery positive terminal and electric AT oil pump relay terminal D.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

|

|

6

|

INSPECT ELECTRIC AT OIL PUMP RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Electric AT oil pump relay is removed.

• Switch the ignition ON (engine off).

• Measure the voltage at the electric AT oil pump relay terminal A (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to Step 9.

|

|

No

|

Inspect the ENGINE3 15 A fuse.

• If the fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between ENGINE3 15 A fuse and electric AT oil pump relay terminal A.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a short to ground.

• Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

• If the fuse is normal:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between main relay terminal C and electric AT oil pump relay terminal A.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

|

|

7

|

INSPECT ELECTRIC AT OIL PUMP RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Electric AT oil pump relay is removed.

• Measure the voltage at the electric AT oil pump relay terminal D (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Remove the service plug.

Inspect the AT PUMP 15 A fuse.

• If the fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between AT PUMP 15 A fuse and electric AT oil pump relay terminal D.

If there is a common connector:

-

• Determine the malfunctioning location by inspecting the common connector and terminals for corrosion, damage, or disconnection and by inspecting the DC-DC converter (i-ELOOP) terminal 4A-related wiring harness for short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which is shorted to ground, or the DC-DC converter (i-ELOOP) terminal 4A-related wiring harness.

• Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

• If the fuse is normal:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between DC-DC converter (i-ELOOP) terminal 4A and electric AT oil pump relay terminal D.

If there is a common connector:

-

• Determine the malfunctioning location by inspecting the common connector and terminals for corrosion, damage, or disconnection and by inspecting the DC-DC converter (i-ELOOP) terminal 4A-related wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit, or the DC-DC converter (i-ELOOP) terminal 4A-related wiring harness.

Reinstall the service plug.

|

|

8

|

INSPECT ELECTRIC AT OIL PUMP RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Electric AT oil pump relay is removed.

• Switch the ignition ON (engine off).

• Measure the voltage at the electric AT oil pump relay terminal A (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the ENGINE3 15 A fuse.

• If the fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between ENGINE3 15 A fuse and electric AT oil pump relay terminal A.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a short to ground.

• Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

• If the fuse is normal:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between main relay terminal C and electric AT oil pump relay terminal A.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

|

|

9

|

INSPECT ELECTRIC AT OIL PUMP CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the electric AT oil pump connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT ELECTRIC AT OIL PUMP GROUND CIRCUIT FOR OPEN CIRCUIT

• Electric AT oil pump relay is removed.

• Verify that the electric AT oil pump connector is disconnected.

• Inspect for continuity between electric AT oil pump terminal G (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between electric AT oil pump terminal G and body ground.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Inspect for the following:

-

― Open circuit between electric AT oil pump and body ground

― Loose or lifting ground point

-

• Repair or replace the malfunctioning part.

|

|

11

|

INSPECT ELECTRIC AT OIL PUMP POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Electric AT oil pump relay is removed.

• Verify that the electric AT oil pump connector is disconnected.

• Inspect for continuity between electric AT oil pump relay terminal C (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between electric AT oil pump relay terminal C and electric AT oil pump terminal A.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

|

|

No

|

Go to the next step.

|

|

12

|

INSPECT ELECTRIC AT OIL PUMP POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Electric AT oil pump relay is removed.

• Verify that the electric AT oil pump connector is disconnected.

• Inspect for continuity between electric AT oil pump relay terminal C (wiring harness-side) and electric AT oil pump terminal A (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between electric AT oil pump relay terminal C and electric AT oil pump terminal A.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

|

|

13

|

INSPECT TCM CONNECTOR CONDITION

• Disconnect the TCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals.

|

|

No

|

Go to the next step.

|

|

14

|

INSPECT TCM CIRCUIT FOR SHORT TO GROUND

• Electric AT oil pump relay is removed.

• Verify that the electric AT oil pump and TCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

-

― Electric AT oil pump relay terminal E

― Electric AT oil pump terminal C

― Electric AT oil pump terminal E

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Electric AT oil pump relay terminal E—TCM terminal 1Y

• Electric AT oil pump terminal C—TCM terminal 1Z

• Electric AT oil pump terminal E—TCM terminal 1AF

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

|

|

No

|

Go to the next step.

|

|

15

|

INSPECT TCM CIRCUIT FOR OPEN CIRCUIT

• Electric AT oil pump relay is removed.

• Verify that the electric AT oil pump and TCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

-

― Electric AT oil pump relay terminal E—TCM terminal 1Y

― Electric AT oil pump terminal C—TCM terminal 1Z

― Electric AT oil pump terminal E—TCM terminal 1AF

• Is there continuity?

|

Yes

|

Replace the electric AT oil pump.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Electric AT oil pump relay terminal E—TCM terminal 1Y

• Electric AT oil pump terminal C—TCM terminal 1Z

• Electric AT oil pump terminal E—TCM terminal 1AF

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

|

|

16

|

Verify the test results.

• If normal, return to the diagnostic index to service any additional symptoms.

• If a malfunction remains, inspect the related Service Information and perform the repair or diagnosis.

-

― If the vehicle is repaired, troubleshooting is completed.

― If the vehicle is not repaired or additional diagnostic information is not available, replace the PCM.

|