|

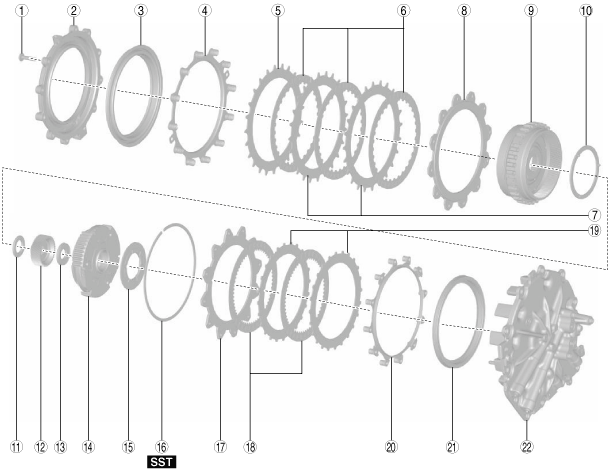

END COVER COMPONENT DISASSEMBLY

id051700661200

Structural view

bcw6ja00000250

|

|

1

|

8 bolts

|

|

2

|

Brake housing

|

|

3

|

2-6 brake piston

|

|

4

|

Springs and retainer component

|

|

5

|

Retaining plate

|

|

6

|

Drive plate

|

|

7

|

Driven plate

|

|

8

|

Retaining plate

|

|

9

|

Rear internal gear and reduction internal gear component

|

|

10

|

Thrust washer

|

|

11

|

Thrust needle bearing

|

|

12

|

Reduction sun gear

|

|

13

|

Thrust needle bearing

|

|

14

|

Reduction planetary gear

|

|

15

|

Thrust washer

|

|

16

|

Snap ring

|

|

17

|

Retaining plate

|

|

18

|

Drive plate

|

|

19

|

Driven plate

|

|

20

|

Springs and retainer component

|

|

21

|

R-3-5 brake piston

|

|

22

|

End cover

|

Disassembly Procedure

1. Perform a simple inspection of the 2-6 brake using the following procedure:

bcw6ja00000251

|

2. Perform a simple inspection of the R-3-5 brake using the following procedure:

bcw6ja00000252

|

3. Remove the brake housing using the following procedure:

bcw6ja00000253

|

|

1

|

8 bolts

|

|

2

|

Brake housing

|

bcw6ja00000254

|

bcw6ja00000255

|

4. Remove the 2-6 brake piston from the brake housing using the following procedure:

bcw6ja00000256

|

bcw6ja00000257

|

5. Remove the springs and retainer component.

bcw6ja00000258

|

6. Remove the retaining plate.

bcw6ja00000259

|

7. Remove the drive plates and driven plates.

bcw6ja00000028

|

8. Remove the retaining plate.

bcw6ja00000260

|

9. Remove the rear internal gear and reduction internal gear component.

bcw6ja00000026

|

10. Remove the reduction internal gear from the rear internal gear and reduction internal gear component using the following procedure:

bcw6ja00000261

|

bcw6ja00000262

|

11. Remove the thrust washer.

bcw6ja00000263

|

12. Remove the thrust needle bearing.

bcw6ja00000264

|

13. Remove the reduction sun gear.

bcw6ja00000265

|

14. Remove the thrust needle bearing.

bcw6ja00000266

|

15. Remove the reduction planetary gear.

bcw6ja00000267

|

16. Remove the thrust washer.

bcw6ja00000268

|

17. Remove the snap ring using the following procedure:

bcw6ja00000050

|

bcw6ja00000051

|

bcw6ja00000648

|

bcw6ja00000649

|

bcw6ja00000650

|

bcw6ja00000053

|

bcw6ja00000054

|

bcw6ja00000269

|

18. Remove the retaining plate.

bcw6ja00000270

|

19. Remove the drive plates and driven plates.

bcw6ja00000055

|

20. Remove the springs and retainer component.

bcw6ja00000271

|

21. Remove the R-3-5 brake piston using the following procedure:

bcw6ja00000272

|

bcw6ja00000273

|

22. Clean the disassembled parts. (See AUTOMATIC TRANSAXLE CLEANING.)

23. Perform the following inspection and replace a malfunctioning part with a new one.