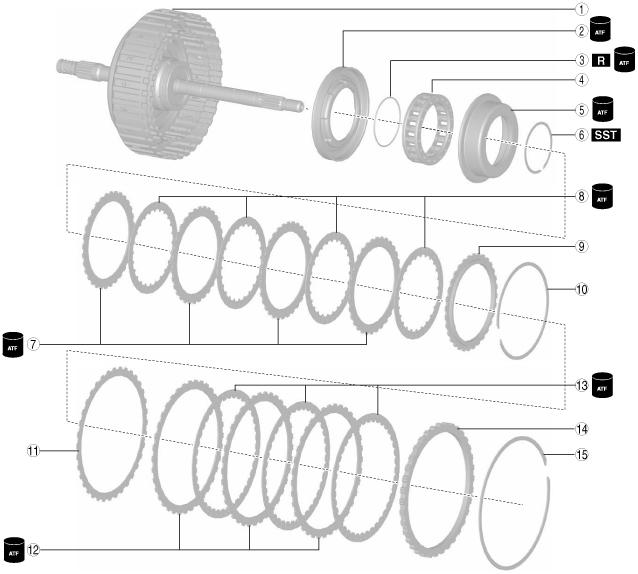

CLUTCH COMPONENT ASSEMBLY

id051700663700

Structural view

|

1

|

Drum and shaft component

|

|

2

|

High clutch piston

|

|

3

|

O-ring (outer diameter approx. 53.2 mm {2.09 in}, thickness approx. 1.6 mm {0.063 in})

|

|

4

|

Springs and retainer component (outer diameter approx. 78.5 mm {3.09 in})

|

|

5

|

Seal plate

|

|

6

|

Snap ring (outer diameter approx. 56.5 mm {2.22 in})

|

|

7

|

Driven plate (inner diameter approx. 94.1 mm {3.70 in})

|

|

8

|

Drive plate (outer diameter approx. 111.7 mm {4.398 in})

|

|

9

|

Retaining plate (inner diameter approx. 94.1 mm {3.70 in})

|

|

10

|

Snap ring (outer diameter approx. 122.3 mm {4.815 in}) (selection)

|

|

11

|

Wave spring

|

|

12

|

Driven plate (inner diameter approx. 135.2 mm {5.323 in})

|

|

13

|

Drive plate (outer diameter approx. 149.9 mm {5.902 in})

|

|

14

|

Retaining plate (inner diameter approx. 135.2 mm {5.323 in})

|

|

15

|

Snap ring (outer diameter approx. 158.8 mm {6.252 in} (selection)

|

Assembly Procedure

1. Assemble the high clutch piston using the following procedure:

- (1) Apply ATF (ATF FZ) to the high clutch piston lip.

- (2) Assemble the high clutch piston.

-

2. Assemble the O-ring using the following procedure:

-

Caution

-

• If a O-ring is reused it could cause ATF leakage, therefore use a new O-ring.

- (1) Apply ATF (ATF FZ) to the new O-ring.

- (2) Assemble the new O-rings.

-

-

Note

-

• O-ring size: Outer diameter approx. 53.2 mm {2.09 in}, thickness approx. 1.6 mm {0.063 in}

3. Assemble the springs and retainer component.

-

Note

-

• Springs and retainer component size: Outer diameter approx. 78.5 mm {3.09 in}

4. Assemble the seal plate using the following procedure:

- (1) Apply ATF (ATF FZ) to the seal plate lip.

- (2) Assemble the seal plate.

-

5. Assemble the snap ring using the following procedure:

-

Note

-

• Snap ring size: Outer diameter approx. 56.5 mm {2.22 in}

- (1) Set the snap ring to the top of the seal plate.

-

- (2) Install the SSTs.

-

- (3) Set the SSTs and part to the press as shown in the figure.

-

-

Caution

-

• Set the SST (49 D019 003) to the center of the seal plate.

A :Press

- (4) Press down the SSTs using the press until the snap ring groove of the drum and shaft component comes out.

-

-

Caution

-

• If the press is pressed down excessively, surrounding parts could be damaged.Stop pressing down when the snap ring groove of the drum and shaft component comes out.

A :Snap ring groove

- (5) Assemble the snap ring.

-

-

Caution

-

• After assembling the snap ring, verify that the snap ring is securely inserted into the bottom of the snap ring groove.

A :Snap ring

- (6) Take the SSTs and part off the press.

-

- (7) Remove the SSTs.

-

6. Assemble the drive plates and driven plates using the following procedure:

-

Note

-

• Drive plate size: Outer diameter approx. 111.7 mm {4.398 in}

• Driven plate size: Inner diameter approx. 94.1 mm {3.70 in}

- (1) Apply ATF (ATF FZ) to the drive plates and driven plates.

-

-

Caution

-

• If the drive plate is replaced with a new one, immerse it in ATF (ATF FZ) for 2 h or more to permeate the facing with ATF.

- (2) Assemble the drive plates and driven plates.

-

-

Assembly order

-

Driven plate—drive plate—driven plate—drive plate—driven plate—drive plate—driven plate—drive plate

A :Drive plate

B :Driven plate

7. Assemble the retaining plate.

-

Note

-

• Retaining plate size: Inner diameter approx. 94.1 mm {3.70 in}

8. Assemble the snap ring using the following procedure:

-

Note

-

• Snap ring size: Outer diameter approx. 122.3 mm {4.815 in}

- (1) Measure the high clutch clearance and select the appropriate snap ring. (See HIGH CLUTCH CLEARANCE MEASUREMENT/ADJUSTMENT.)

-

-

Note

-

• If the snap ring is assembled for the high clutch clearance measurement/adjustment, the following snap ring assembly procedure is not necessary.

- (2) Assemble the selected snap ring in Step (1).

-

-

Caution

-

• After assembling the snap ring, verify that the snap ring is securely inserted into the bottom of the snap ring groove.

A :Selection

9. Assemble the wave spring.

10. Assemble the drive plates and driven plates using the following procedure:

-

Note

-

• Drive plate size: Outer diameter approx. 149.9 mm {5.902 in}

• Driven plate size: Inner diameter approx. 135.2 mm {5.323 in}

- (1) Apply ATF (ATF FZ) to the drive plates and driven plates.

-

-

Caution

-

• If the drive plate is replaced with a new one, immerse it in ATF (ATF FZ) for 2 h or more to permeate the facing with ATF.

- (2) Assemble the drive plates and driven plates.

-

-

Assembly order

-

Driven plate—drive plate—driven plate—drive plate—driven plate—drive plate

A :Drive plate

B :Driven plate

11. Assemble the retaining plate.

-

Note

-

• Retaining plate size: Inner diameter approx. 135.2 mm {5.323 in}

12. Assemble the snap ring using the following procedure:

-

Note

-

• Snap ring size: Outer diameter approx. 158.8 mm {6.252 in}

- (1) Measure the low clutch clearance and select the appropriate snap ring. (See LOW CLUTCH CLEARANCE MEASUREMENT/ADJUSTMENT.)

-

-

Note

-

• If the snap ring is assembled for the low clutch clearance measurement/adjustment, the following snap ring assembly procedure is not necessary.

- (2) Assemble the selected snap ring in Step (1) to the position shown in the figure.

-

-

Caution

-

• Assemble so that the end gap of the snap ring is positioned diagonally opposed to the end gap of the snap ring for the high clutch.

• After assembling the snap ring, verify that the snap ring is securely inserted into the bottom of the snap ring groove.

A :Selection

A :Snap ring (low clutch)

B :Snap ring (high clutch)

13. Perform a simple inspection of the low clutch and high clutch using the following procedure:

- (1) Set the oil pump on the workbench as shown in the figure.

-

-

Note

-

• Using the rubber plates, adjust the alignment surface of the oil pump with the transaxle case so that it is level.

A :Rubber plate

- (2) Assemble the thrust washer to the clutch component using the following procedure:

-

-

Note

-

• Thrust washer size: Inner diameter approx. 58.7 mm {2.31 in}

- 1) To prevent the thrust washer from dropping out, apply ATF (ATF FZ) to the thrust washer.

- 2) Assemble the thrust washer.

-

- (3) Assemble the parts assembled together in Step (2) to the oil pump.

-

- (4) Blow compressed air into the oil passage shown in the figure and verify the operation condition of the low clutch.

-

-

Warning

-

• Always wear protective eye wear when using the air compressor. Otherwise, ATF or dirt particles blown off by the air compressor could get into the eyes.

-

Caution

-

• To prevent damage to parts, always use an air compressor which is adjusted to the indicated pressure.

-

Compressed air pressure

-

0.39—0.44 MPa {4.0—4.4 kgf/cm2, 57—63 psi}

-

• If there is any malfunction, perform disassembly again, verify the cause and repair the applicable part.(See

CLUTCH COMPONENT DISASSEMBLY.)

- (5) Blow compressed air into the oil passage shown in the figure and verify the operation condition of the high clutch.

-

-

Warning

-

• Always wear protective eye wear when using the air compressor. Otherwise, ATF or dirt particles blown off by the air compressor could get into the eyes.

-

Caution

-

• To prevent damage to parts, always use an air compressor which is adjusted to the indicated pressure.

-

Compressed air pressure

-

0.39—0.44 MPa {4.0—4.4 kgf/cm2, 57—63 psi}

-

• If there is any malfunction, perform disassembly again, verify the cause and repair the applicable part. (See

CLUTCH COMPONENT DISASSEMBLY.)

- (6) Remove the clutch component.

-

- (7) Remove the thrust washer.

-

- (8) Take the oil pump off the rubber plates.

-