|

1

|

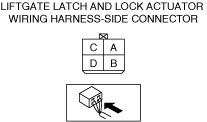

INSPECT LIFTGATE LATCH AND LOCK ACTUATOR CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

2

|

INSPECT LIFTGATE LATCH SWITCH FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

3

|

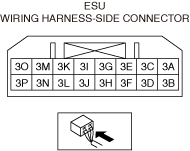

INSPECT ELECTRICAL SUPPLY UNIT (ESU) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

4

|

INSPECT LIFTGATE LATCH SWITCH SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

INSPECT ELECTRICAL SUPPLY UNIT (ESU) FOR MALFUNCTION DEPENDING ON REPEATABILITY

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Perform the DTC inspection for the body control module (BCM) with the liftgate closed.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to repair completion verification 2.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Perform the DTC inspection for the body control module (BCM) with the liftgate closed.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the body control module (BCM), then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTC IS DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|