|

1

|

DETERMINE IF MALFUNCTION CAUSED BY A/C SYSTEM OPERATION

• Verify the A/C system operation.

• Is the A/C system operation normal?

|

Yes

|

Go to the next step.

|

|

No

|

Perform the symptom troubleshooting “A/C DOES NOT WORK SUFFICIENTLY” and “A/C IS ALWAYS ON OR A/C COMPRESSOR RUNS CONTINUOUSLY”.

|

|

2

|

DETERMINE IF MALFUNCTION CAUSED BY ATX BODY

• Compare the malfunction symptom with the i-stop system stop condition.

• Is there any shock or slippage during acceleration with the i-stop system disabled?

|

Yes

|

Perform the applicable symptom troubleshooting procedure.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY DTC

• Perform the DTC inspection for the following modules.

-

― PCM

― TCM

― DSC HU/CM

― SAS control module

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

4

|

DETERMINE IF MALFUNCTION CAUSE IS BRAKE FLUID PRESSURE SENSOR SIGNAL OR OTHER

• Put the vehicle in an i-stop condition (engine stopped).

• Monitor the PCM PID BRK_FLD_PRES using the M-MDS while the brake is depressed and held with the i-stop function operating.

• Does the monitoring value change?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, repeat the inspection from Step 1.

-

― If the malfunction recurs, perform the following procedure.

-

• Replace the DSC HU/CM. (Brake fluid pressure sensor (built-into DSC HU/CM) or DSC HU/CM brake pressure hold function malfunction.)

― Perform the repair completion verification 1.

|

|

No

|

Go to the next step.

|

|

5

|

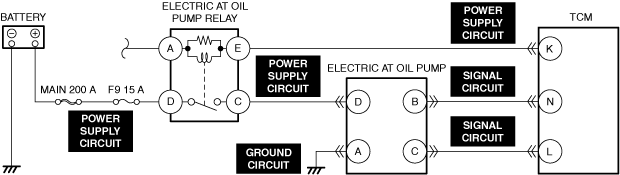

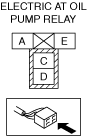

INSPECT ELECTRIC AT OIL PUMP RELAY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

6

|

INSPECT ELECTRIC AT OIL PUMP RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit and short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

7

|

INSPECT ELECTRIC AT OIL PUMP CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

8

|

INSPECT ELECTRIC AT OIL PUMP GROUND CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

9

|

INSPECT ELECTRIC AT OIL PUMP POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

10

|

INSPECT ELECTRIC AT OIL PUMP POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

11

|

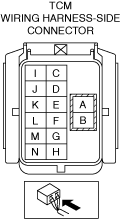

INSPECT TCM CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

12

|

INSPECT TCM POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

13

|

INSPECT TCM POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, replace the electric AT oil pump and perform the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

14

|

INSPECT RELATED PART CONDITION

• Inspect the following:

-

― Lack of ATF

― Brake dragging

• Are all items normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

15

|

INSPECT DRIVE BELT FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

16

|

INSPECT FOR FUEL LEAKAGE FROM FUEL SYSTEM

• Visually inspect the following:

-

― Fuel leakage from the fuel tank, fuel pump, hose, pipe, fuel injector, supply pump, common rail

― Cracking and damage in fuel hose and pipe

― Clamp installation condition for each hose and pipe

― Fuel pipe securing condition due to deterioration such as rubber of clamp

• Are all items normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

17

|

INSPECT FUEL INJECTION SYSTEM RELATED PARTS

• Inspect the following parts:

-

― Fuel pressure relief valve

• Are all items normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

18

|

INSPECT FOR MALFUNCTION DUE TO POOR FUEL

• Does the symptom disappear?

|

Yes

|

Advise the customer as to the change in the fuel used.

|

|

No

|

Remove the accumulated matter in the cylinder head using the following procedure, then go to the next step.

• Carbon remover

• Overhauling

|

|

19

|

DETERMINE IF MALFUNCTION IS DUE TO EXCESSIVE ENGINE SPEED RESISTANCE

• Rotate the crankshaft pulley lock bolt clockwise using a wrench.

• Can the bolt be rotated?

|

Yes

|

Go to Step 21.

|

|

No

|

Go to the next step.

|

|

20

|

INSPECT FOR MALFUNCTION DUE TO EXCESSIVE MECHANICAL RESISTANCE OF ENGINE ACCESSORIES

• Remove all drive belts from engine accessories.

-

Caution

-

• Do not run the engine with the drive belts of engine accessories removed. Otherwise the engine could be damaged from overheating.

• Start the engine.

• Is cranking possible? (Does engine start?)

|

Yes

|

Mechanical resistance in engine accessories.

• Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

No

|

Go to the next step.

|

|

21

|

INSPECT ENGINE COMPRESSION

• Inspect the engine compression.

• Are compression pressures within specification?

|

Yes

|

Perform the repair completion verification 1.

|

|

No

|

Go to the next step.

|

|

22

|

INSPECT FOR MALFUNCTION DUE TO DEVIATED VALVE TIMING

• Inspect the valve timing (timing chain installation condition).

• Is the valve timing normal?

|

Yes

|

Go to the next step.

|

|

No

|

Adjust the valve timing to the correct timing and perform the repair completion verification 1.

|

|

23

|

INSPECT FOR MALFUNCTION DUE TO INTERNAL ENGINE WEAR, DAMAGE

• Inspect for the following engine internal parts:

-

― Cylinder

― Piston ring

― Intake valve

― Exhaust valve

― Such as cylinder head gasket

• Are all items normal?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, replace the lower case, then perform the repair completion verification 1. (Fuel may not inject normally.)

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF MALFUNCTION IS CAUSED BY NOT PERFORMING PCM REPROGRAMMING

• Verify repair information and verify that there is a new calibration in the PCM.

• Is there a new calibration in the PCM?

|

Yes

|

Perform the PCM reprogramming and verify if the malfunction symptom was corrected.

• If the malfunction recurs, replace the PCM.

|

|

No

|

Replace the PCM.

|