|

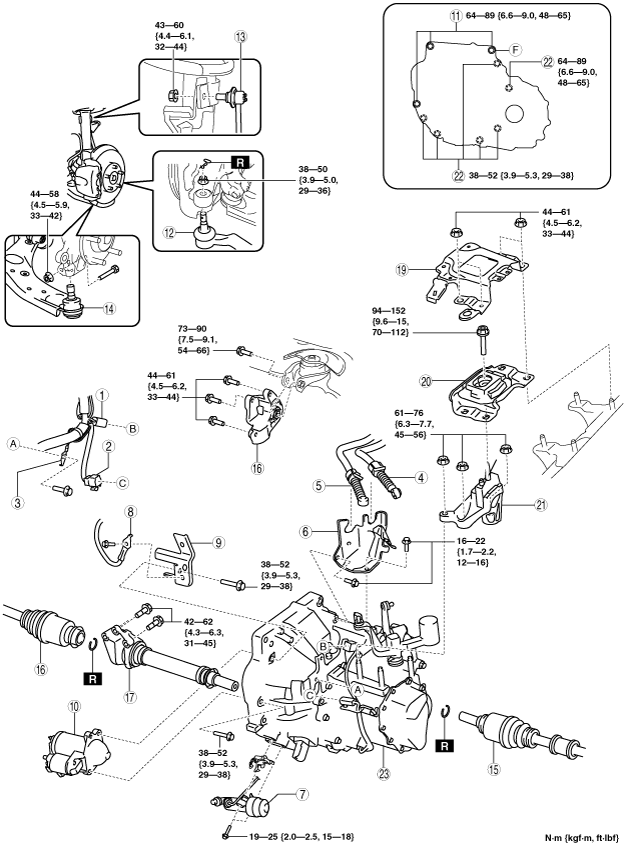

MANUAL TRANSAXLE REMOVAL/INSTALLATION [F35M-R]

id0515a1800600

1. Remove the battery cover. (See BATTERY REMOVAL/INSTALLATION [ZY, Z6].)

2. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [ZY, Z6].)

3. Remove the following parts:

4. Drain the transaxle oil into a suitable container. (See TRANSAXLE OIL REPLACEMENT [F35M-R].)

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Add the specified amount of specified transaxle oil. (See TRANSAXLE OIL REPLACEMENT [F35M-R].)

am3zzw00005424

|

|

1

|

Neutral switch connector

|

|

2

|

Back-up light switch connector

|

|

3

|

Ground

|

|

4

|

Shift cable

|

|

5

|

Select cable

|

|

6

|

Cable bracket

|

|

7

|

Clutch release cylinder

|

|

8

|

Ground

|

|

9

|

Wiring harness bracket

|

|

10

|

Starter

|

|

11

|

Transaxle mounting bolt (upper side)

|

|

12

|

Stabilizer control link

|

|

13

|

Tie-rod end ball joint

|

|

14

|

Lower arm ball joint

|

|

15

|

Drive shaft (LH)

|

|

16

|

Drive shaft (RH)

|

|

17

|

Joint shaft

|

|

18

|

No.1 engine mount bracket

|

|

19

|

Battery tray bracket

|

|

20

|

No.4 engine mount rubber

|

|

21

|

No.4 engine mount bracket

|

|

22

|

Transaxle mounting bolt (lower side)

|

|

23

|

Manual transaxle

|

Shift Cable and Select Cable Removal Note

1. Remove the shift and selector cable outer ends as shown in the figure.

am3uuw00002130

|

2. Remove the both shift cable end and select cable end using a fastener remover.

am2zzw00000188

|

No.1 Engine Mount Rubber Removal Note

1. Loosen the bolt shown in the figure.

am3zzw00006003

|

2. Remove the bolt shown in the figure.

am3zzw00006004

|

No.4 Engine Mount Removal Note

1. Detach the hose clip shown in the figure.

am3zzw00005425

|

2. Remove the bracket bolt shown in the figure and set the bracket aside to prevent interference with the SST.

am3zzw00005426

|

3. Remove the brake vacuum hose bracket bolt, then set the brake vacuum hose out of the way.

am3zzw00006900

|

4. Set the fuel pipe bracket out of the way to prevent interference with the SST as shown in the figure.

am3zzw00008592

|

5. Using the bolts part number 99794 1025 or M10×1.25, length 25 mm {0.98 in} to install the SST (49 UN30 3050) to the position shown in the figure.

am2zzw00000190

|

6. Install front foot No.2 to the left/right front shaft of the SST (49 C017 5A0).

am2zzw00000191

|

7. As shown in the figure, set the rear shafts of the SST to the left and right shock absorber upper bolts.

am3zzw00005427

|

8. As shown in the figure, set the front shaft groove of the SST to the folded part of the left and right body frames.

am3zzw00005428

|

9. Adjust the height of the left and right side bars so that they are leveled, then tighten each part of the SST.

am3zzw00005429

|

10. Verify that the SST is properly set and the engine is securely hung.

11. Remove the No.4 engine mount.

Manual Transaxle Removal Note

1. Adjust the SST and lean the engine toward the transaxle.

am3zzw00005429

|

2. Support the transaxle on a jack.

am2zzw00000198

|

3. Remove the transaxle mounting bolts.

4. Remove the transaxle.

Manual Transaxle Installation Note

1. Set the transaxle on a jack and lift into place.

2. Install the transaxle mounting bolts.

am2zzw00001941

|

3. Adjust the SST (49 C017 5A0) so that the engine is located at the specified position.

No.1 Engine Mount and No.4 Engine Mount Installation Note

1. Install the No.4 engine mount bracket.

am3zzw00006005

|

2. Tighten the No.4 engine mount rubber installation bolt.

am3zzw00006006

|

3. Tighten the No.1 engine mount rubber installation bolts in the order shown.

am3zzw00006007

|

4. Tighten the No.4 engine mount rubber and battery tray bracket installation nuts as shown in the figure.

am3zzw00006008

|