|

1

|

VERIFY FREEZE FRAME DATA HAS BEEN RECORDED

• Has the FREEZE FRAME DATA been recorded?

|

Yes

|

Go to the next step.

|

|

No

|

Record the FREEZE FRAME DATA on the repair order, then go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT VSS CONNECTOR FOR POOR CONNECTION

• Turn the ignition switch to the LOCK position.

• Disconnect the VSS connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is the connection normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the pin or connector, then go to Step 11.

|

|

4

|

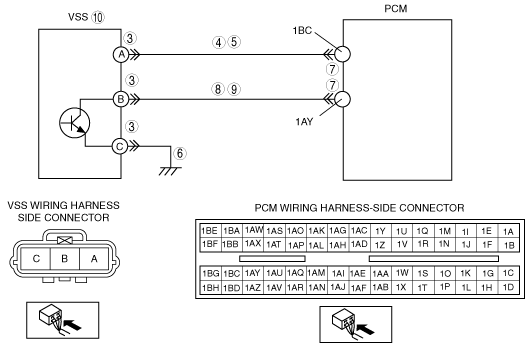

INSPECT VSS POWER CIRCUIT FOR OPEN CIRCUIT

• Verify that the VSS connector is disconnected.

• Turn the ignition switch to the ON position (engine off).

• Inspect the voltage between VSS terminal A (wiring harness-side) and ground.

• Is the voltage B+?

|

Yes

|

Go to Step 6.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT VSS POWER CIRCUIT FOR SHORT TO GROUND

• Turn the ignition switch to the LOCK position.

• Inspect for continuity between VSS terminal A (wiring harness-side) and ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness, then go to Step 11.

|

|

6

|

INSPECT VSS GROUND CIRCUIT FOR OPEN CIRCUIT

• Verify that the VSS connector is disconnected.

• Inspect for continuity between VSS (wiring harness-side) terminal C and ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness, then go to Step 11.

|

|

7

|

INSPECT PCM CONNECTOR FOR POOR CONNECTION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is the connection normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the pin or connector, then go to Step 11.

|

|

8

|

INSPECT VEHICLE SPEED SIGNAL CIRCUIT FOR OPEN CIRCUIT

• Disconnect the PCM connector and VSS connector.

• Inspect for continuity between VSS terminal B and PCM terminal 1AX (ZY)/1J (LF).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness, then go to Step 11.

|

|

9

|

INSPECT VEHICLE SPEED SIGNAL CIRCUIT FOR SHORT TO GROUND

• Verity that the VSS connector and PCM connector are disconnected.

• Inspect for continuity between PCM terminal 1AX (ZY)/1J (LF) and body ground.

• Is there continuity?

|

Yes

|

Repair or replace the wiring harness, then go to the next step.

|

|

No

|

Replace the VSS, then go to the next step.

|

|

10

|

INSPECT VEHICLE SPEED SENSOR

• Is VSS normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the VSS, then go to Step 11.

|

|

11

|

VERIFY TROUBLESHOOTING OF DTC P0720 COMPLETED

• Make sure to reconnect all the disconnected connectors.

• Clear the DTC from the memory using the M-MDS.

• Drive the vehicle under the following conditions for 4.5 s or more while monitoring PIDs.

-

― Engine coolant temp (ECT PID): 60 °C {140 °F} or more

― Drive in D or M range

― Frequency of input/turbine speed sensor: 800 Hz or more

• Is the PENDING CODE present?

|

Yes

|

Replace the PCM, then go to the next step.

|

|

No

|

No concern is detected. Go to the next step.

|

|

12

|

VERIFY AFTER REPAIR PROCEDURE

• Perform the "After Repair Procedure".

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|