|

1

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY RELATED PENDING CODE AND/OR DTC

• Switch the ignition to off, then to ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Is the PENDING CODE/DTC P0704:00 also present?

|

Yes

|

Go to the applicable PENDING CODE or DTC inspection.

|

|

No

|

Go to the next step.

|

|

3

|

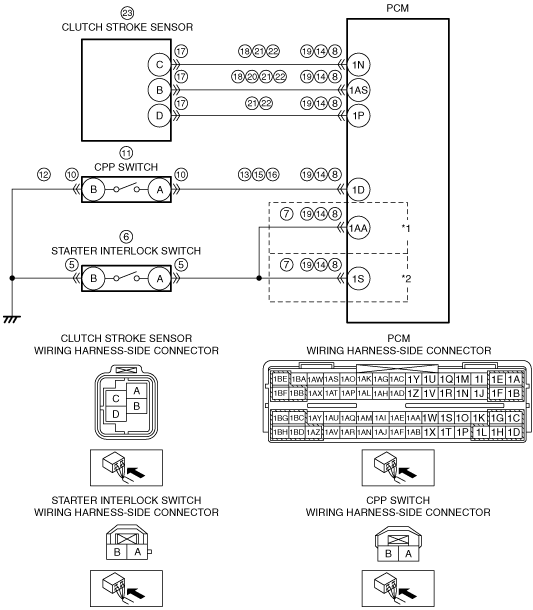

INSPECT INSTALLATION OF CPP SWITCH, CLUTCH STROKE SENSOR AND STARTER INTERLOCK SWITCH

• Inspect if the CPP switch, clutch stroke sensor and starter interlock switch are loosely installed.

• Are the CPP switch, clutch stroke sensor and starter interlock switch installed securely?

|

Yes

|

Go to the next step.

|

|

No

|

Retighten the malfunctioning switch and/or sensor, then go to Step 24.

|

|

4

|

DETERMINE MALFUNCTIONING SYSTEM

-

― PCM PID:

-

• CPP (OFF/ON)

• CPP (%)

― Advanced keyless entry and push button start system PID (Vehicles with advanced keyless entry and push button start system)

-

• START_LC_SW

― PCM terminal voltage (Vehicles without advanced keyless entry and push button start system)

-

• Terminal 1AA

• Is there any malfunction?

|

Yes

|

If the START_LC_SW PID is not normal (Vehicles with advanced keyless entry and push button start system):

• Go to the next step.

If the PCM terminal 1AA voltage is not normal (Vehicles without advanced keyless entry and push button start system):

• Go to the next step.

If the CPP PID (OFF/ON) is not normal:

• Go to Step 10.

If the CPP PID (%) is not normal:

• Go to Step 17.

|

|

No

|

Intermittent concern exists.

• Perform the “INTERMITTENT CONCERN TROUBLESHOOTING” procedure.

|

|

5

|

INSPECT STARTER INTERLOCK SWITCH CONNECTOR CONDITION

• Switch the ignition to off.

• Disconnect the starter interlock switch connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the terminal and/or connector, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

6

|

INSPECT STARTER INTERLOCK SWITCH

• Inspect the starter interlock switch.

• Is there any malfunction?

|

Yes

|

Replace the starter interlock switch, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

7

|

INSPECT STARTER INTERLOCK SWITCH CIRCUIT FOR SHORT TO GROUND

• Starter interlock switch connector is disconnected.

• Inspect for continuity between starter interlock switch terminal A (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

If the short to ground circuit could be detected:

• Repair or replace the wiring harness for a possible short to ground.

If the short to ground circuit could not be detected:

• Replace the PCM (short to ground in PCM internal circuit).

Go to Step 24.

|

|

No

|

Go to the next step.

|

|

8

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the terminal and/or connector, then go to Step 24.

|

|

No

|

Vehicles with advanced keyless entry and push button start system.

• Go to the next step.

Vehicles without advanced keyless entry and push button start system.

• Repeat Step 4.

|

|

9

|

INSPECT KEYLESS CONTROL MODULE CONNECTOR CONDITION

• Disconnect the keyless control module connectors.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the terminal and/or connector, then go to Step 24.

|

|

No

|

Repeat Step 4.

|

|

10

|

INSPECT CPP SWITCH CONNECTOR CONDITION

• Switch the ignition to off.

• Disconnect the CPP switch connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the terminal and/or connector, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

11

|

INSPECT CPP SWITCH

• Inspect the CPP switch.

• Is there any malfunction?

|

Yes

|

Replace the CPP switch, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

12

|

INSPECT CPP SWITCH GROUND CIRCUIT FOR OPEN CIRCUIT

• CPP switch connector is disconnected.

• Inspect for continuity between CPP switch terminal B (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness for a possible open circuit, then go to Step 24.

|

|

13

|

INSPECT CPP SWITCH SIGNAL CIRCUIT FOR SHORT TO GROUND

• CPP switch connector is disconnected.

• Inspect for continuity between CPP switch terminal A (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

If the short to ground circuit could be detected:

• Repair or replace the wiring harness for a possible short to ground.

If the short to ground circuit could not be detected:

• Replace the PCM (short to ground in PCM internal circuit).

Go to Step 24.

|

|

No

|

Go to the next step.

|

|

14

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the terminal and/or connector, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

15

|

INSPECT CPP SWITCH SIGNAL CIRCUIT FOR OPEN CIRCUIT

• CPP switch and PCM connectors are disconnected.

• Inspect for continuity between CPP switch terminal A (wiring harness-side) and PCM terminal 1D (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness for a possible open circuit, then go to Step 24.

|

|

16

|

INSPECT CPP SWITCH CIRCUIT FOR SHORT TO POWER SUPPLY

• CPP switch and PCM connectors are disconnected.

• Switch the ignition to ON (engine off).

• Measure the voltage at the CPP switch terminal A (wiring harness-side).

• Is there any voltage?

|

Yes

|

Repair or replace the wiring harness for a possible short to power supply, then go to Step 24.

|

|

No

|

Repeat Step 4.

|

|

17

|

INSPECT CLUTCH STROKE SENSOR CONNECTOR CONDITION

• Switch the ignition to off.

• Disconnect the clutch stroke sensor connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the terminal and/or connector, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

18

|

INSPECT CLUTCH STROKE SENSOR CIRCUIT FOR SHORT TO GROUND

• Clutch stroke sensor connector is disconnected.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

-

― Clutch stroke sensor terminal C

― Clutch stroke sensor terminal B

• Is there continuity?

|

Yes

|

If the short to ground circuit could be detected:

• Repair or replace the wiring harness for a possible short to ground.

If the short to ground circuit could not be detected:

• Replace the PCM (short to ground in PCM internal circuit).

Go to Step 24.

|

|

No

|

Go to the next step.

|

|

19

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the terminal and/or connector, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

20

|

INSPECT CLUTCH STROKE SENSOR CIRCUIT FOR SHORT TO POWER SUPPLY

• Clutch stroke sensor and PCM connectors are disconnected.

• Switch the ignition to ON (engine off).

• Measure the voltage at the clutch stroke sensor terminal B (wiring harness-side).

• Is there any voltage?

|

Yes

|

Repair or replace the wiring harness for a possible short to power supply, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

21

|

INSPECT CLUTCH STROKE SENSOR CIRCUIT FOR SHORT TO EACH OTHER

• Clutch stroke sensor and PCM connectors are disconnected.

• Switch the ignition to off.

• Inspect for continuity between clutch stroke sensor terminals C, B and D (wiring harness-side).

• Is there continuity?

|

Yes

|

Repair or replace the wiring harness for a possible short to each other, then go to Step 24.

|

|

No

|

Go to the next step.

|

|

22

|

INSPECT CLUTCH STROKE SENSOR CIRCUIT FOR OPEN CIRCUIT

• Clutch stroke sensor and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

-

― Clutch stroke sensor terminal C—PCM terminal 1N

― Clutch stroke sensor terminal B—PCM terminal 1AS

― Clutch stroke sensor terminal D—PCM terminal 1P

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness for a possible open circuit, then go to Step 24.

|

|

23

|

INSPECT CLUTCH STROKE SENSOR

• Inspect the clutch stroke sensor.

• Is there any malfunction?

|

Yes

|

Replace the clutch stroke sensor, then go to the next step.

|

|

No

|

Repeat Step 4.

|

|

24

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Make sure to reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Perform the KOEO or KOER self test.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

25

|

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|