FUEL PUMP UNIT REMOVAL/INSTALLATION

id011400800900

-

Warning

-

• Fuel is very flammable liquid. If fuel spills or leaks from the pressurized fuel system, it will cause serious injury or death and facility breakage. Fuel can also irritate skin and eyes. To prevent this, always complete the "Fuel Line Safety Procedure", while referring to "BEFORE SERVICE PRECAUTION".

-

• Fuel is very flammable liquid. If fuel spills or leaks from the pressurized fuel system, it will cause serious injury or death and facility breakage. Fuel can also irritate skin and eyes. To prevent this, before performing the fuel pump unit removal/installation, always complete the "Fuel Leak Inspection After Fuel Pump Unit Installation".

1. Follow "BEFORE SERVICE PRECAUTION" before performing any work operations to prevent fuel from spilling from the fuel system. (See BEFORE SERVICE PRECAUTION.)

2. Disconnect the negative battery cable.

3. Remove the fuel tank. (See FUEL TANK REMOVAL/INSTALLATION.)

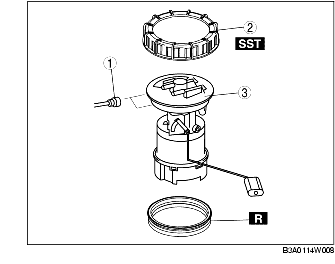

4. Remove in the order indicated in the table.

.

|

1

|

Quick release connector

|

|

2

|

Fuel pump cap

|

|

3

|

Fuel pump unit

|

5. Install in the reverse order of removal.

6. Inspect all related parts by performing "AFTER SERVICE PRECAUTION". (See AFTER SERVICE PRECAUTION.)

Fuel Pump Cap Removal Note

-

Caution

-

• The fuel pump cap could be damaged if the SST is used with any gap between the cap and the SST. Securely attach the SST so that there is no gap between the SST tabs and the side of the cap.

1. Remove the fuel pump cap using the SST.

Fuel Pump Cap Installation Note

-

Note

-

• The fuel pump unit will rotate and cannot be secured in the specified position if there is any gasoline on the gasket. Thoroughly wipe away all gasoline from the gasket.

1. Align the fuel tank and fuel pump unit alignment marks as shown in the figure.

2. Set the SST as shown in the figure.

3. Using the SST, tighten the fuel pump cap within the specified tightening torque without shifting the alignment marks.

-

• If the specified tightening torque cannot be obtained, replace the fuel pump cap and gasket.

-

• If the specified tightening torque cannot be obtained after replacement of the fuel pump cap and gasket, replace the fuel tank.

-

Fuel pump cap tightening torque

-

80-90 N·m {8.2-9.1 kgf·m, 59-66 ft·lbf}

Fuel Leakage Inspection After Pump Unit Installation

1. Before installing the fuel tank, verify that there is no leakage when a pressure of +5.9 kPa {+44 mmHg, +1.7 inHg} is applied to the fuel tank.

2. Install the fuel tank. (See FUEL TANK REMOVAL/INSTALLATION.)

3. Drive the vehicle starting from a standstill and brake suddenly five to six times at a low speed.

4. Stop the vehicle and verify from outside the vehicle that there is no fuel leakage around the fuel pump unit.