DTC P214F:00

Urea tank heater control malfunction

DETECTION CONDITION

• With the following conditions met, the coil conductivity in the urea tank heater is the specified value or more.

MONITORING CONDITIONS

• Ignition switched ON (engine off or on)

• The operation time of the urea tank heater is 50 s or more, or the coil conductivity in the urea tank heater is lower than the value 50 times or more.

• Battery voltage: 11—16 V for a continuous 2 s

• Ignition switched ON (engine off): 5 min or more have elapsed

• The following DTCs are not detected:

-

― Urea temperature sensor: P205A:00― Urea tank heater: P20B9:00, P20BB:00, P20BC:00

-

Note

-

• P0615:00 may be stored if the remaining distance to empty is 0 km {0 mile} and the engine cannot be restarted.• DTC P2BAF:00 is also stored in the PCM and the vehicle speed is restricted.• DTC P1640:00 is also stored in the PCM.

Diagnostic support note

• This is a continuous monitor (CCM).

• The check engine light illuminates if the dosing control unit detects the above malfunction condition in two consecutive drive cycles or in one drive cycle while the DTC for same malfunction has been stored in the dosing control unit.

• PENDING CODE is available if the dosing control unit detects the above malfunction condition first driving cycle.

• FREEZE FRAME DATA/Snapshot data is available.

• DTC is stored in the dosing control unit memory.

FAIL-SAFE FUNCTION

• Restricts the maximum remaining distance to empty.

• Limits the upper limit of the engine speed.

POSSIBLE CAUSE

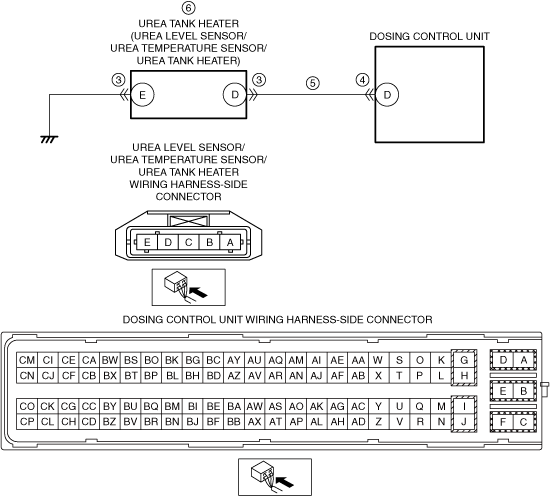

• Urea pump connectors or terminals malfunction

• Dosing control unit connector or terminals malfunction

• Short to power supply in wiring harness between urea tank heater terminal D and dosing control unit terminal D

• Urea tank heater malfunction

• Dosing control unit malfunction