FUEL INJECTOR INSPECTION [LF, L3]

id0114008007a4

Operation Test

1. Carry out the "Fuel Injector Operation Inspection". (See Fuel Injector Operation Inspection.)

-

• If not as specified, perform the further inspection for the fuel injectors.

Resistance Inspection

-

Note

-

• Perform the following test only when directed.

1. Turn the ignition switch to LOCK position.

2. Disconnect the negative battery cable.

3. Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [L3].)

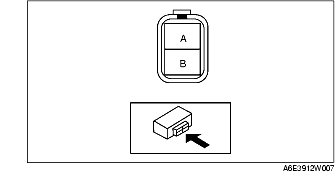

4. Disconnect the fuel injector connectors.

5. Measure the resistance of the fuel injector using an ohmmeter.

-

• If not as specified, replace the fuel injector. (See FUEL INJECTOR REMOVAL/INSTALLATION [LF, L3].)

-

• If as specified but "Operation Test" is failed, carry out the "Circuit Open/Short Inspection". Inspect for open or short circuit.

-

Fuel injector resistance

-

11.4-12.6 ohms [20 °C {68 °F}]

Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See PCM REMOVAL/INSTALLATION [LF, L3].)

2. Inspect the following wiring harness for open or short (continuity check).

Open circuit

-

• If there is no continuity, the circuit is open. Repair or replace the harness.

-

- No.1 cylinder fuel injector terminal B (harness-side) and PCM terminal 4Z.

-

- No.2 cylinder fuel injector terminal B (harness-side) and PCM terminal 4W.

-

- No.3 cylinder fuel injector terminal B (harness-side) and PCM terminal 4AD.

-

- No.4 cylinder fuel injector terminal B (harness-side) and PCM terminal 4AA.

-

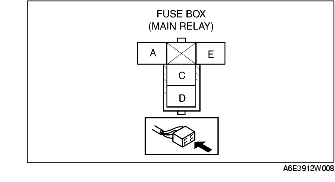

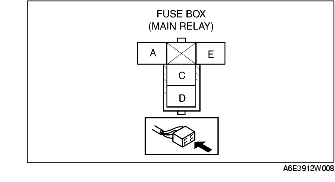

- No.1 cylinder fuel injector terminal A (harness-side) and main relay (harness-side) terminal C through common connector.

-

- No.2 cylinder fuel injector terminal A (harness-side) and main relay (harness-side) terminal C through common connector.

-

- No.3 cylinder fuel injector terminal A (harness-side) and main relay (harness-side) terminal C through common connector.

-

- No.4 cylinder fuel injector terminal A (harness-side) and main relay (harness-side) terminal C through common connector.

Short circuit

-

• If there is continuity, the circuit is short. Repair or replace the harness.

-

- No.1 cylinder fuel injector terminal B (harness-side) and body GND.

-

- No.2 cylinder fuel injector terminal B (harness-side) and body GND.

-

- No.3 cylinder fuel injector terminal B (harness-side) and body GND.

-

- No.4 cylinder fuel injector terminal B (harness-side) and body GND.

-

- No.1 cylinder fuel injector terminal A (harness-side) and power supply.

-

- No.2 cylinder fuel injector terminal A (harness-side) and power supply.

-

- No.3 cylinder fuel injector terminal A (harness-side) and power supply.

-

- No.4 cylinder fuel injector terminal A (harness-side) and power supply.

Fuel Leakage Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Always carry out the following procedure with the engine stopped.

-

Note

-

• Perform the following test only when directed.

1. Complete the "BEFORE REPAIR PROCEDURE". (See BEFORE REPAIR PROCEDURE [LF, L3].)

2. Disconnect the negative battery cable.

3. Remove the fuel injectors together with the fuel distributor with the fuel hose connected. (See FUEL INJECTOR REMOVAL/INSTALLATION [LF, L3].)

4. Fasten the fuel injectors firmly to the fuel distributor with wire.

5. Connect the negative battery cable.

-

Caution

-

• Connecting the wrong check connector terminal may possibly cause malfunction. Carefully connect the specified terminal only.

6. Short the check connector terminal F/P to body GND using a jumper wire.

7. Turn the ignition switch to ON position to operate the fuel pump.

8. Tilt the fuel injectors approx. 60 degrees.

9. Verify that fuel leakage from the fuel injector nozzles is within the specification.

-

• If not as specified, replace the fuel injector.

-

Fuel injector leakage

-

Less than 1 drop/2 minutes

10. Turn the ignition switch to LOCK position and remove the jumper wire.

11. Complete the "AFTER REPAIR PROCEDURE". (See AFTER REPAIR PROCEDURE [LF, L3].)

Volume Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Always carry out the following procedure with the engine stopped.

-

Note

-

• If there is an after market fuel injector tester, perform the following test.

-

• If there is not an after market fuel injector tester, perform "Operation Test", "Resistance Inspection", and "Fuel Leakage Test" to verify whether the fuel injector is okay or not.

1. Complete the "BEFORE REPAIR PROCEDURE". (See BEFORE REPAIR PROCEDURE [LF, L3].)

2. Disconnect the negative battery cable.

3. Remove the fuel injectors. (See FUEL INJECTOR REMOVAL/INSTALLATION [LF, L3].)

4. Connect the fuel injector to the fuel injector tester.

5. Measure the injection volume of each fuel injector using a graduated container.

-

• If not as specified, replace the fuel injector.

-

Fuel injection volume

-

L3 engine: 61-79 ml {61-79 cc, 2.2-2.7 fl oz}/15 sec.

-

LF engine: 53-69 ml {53-69 cc, 1.9-2.4 fl oz}/15 sec.

6. Turn the ignition switch to LOCK position and disconnect the jumper wire.

7. Complete the "AFTER REPAIR PROCEDURE". (See AFTER REPAIR PROCEDURE [LF, L3].)

Atomization

1. Inspect atomization pattern.

-

• If the atomization is malfunctioning, replace the fuel injector.