|

STEP

|

INSPECTION

|

ACTION

|

|

|---|---|---|---|

|

1

|

INSPECT FOR DTCs IN ABS HU/CM

• Have DTCs been stored in memory?

|

Yes

|

Perform the applicable DTC inspection.

(See DTC Table.)

|

|

No

|

Inspect the instrument cluster.

If the instrument cluster is normal, inspect CAN communication.

If instrument cluster has a malfunction, go to the next step.

|

||

|

2

|

VERIFY WHETHER MALFUNCTION IS IN WARNING LIGHTS AND INDICATOR LIGHT'S COMMON POWER SUPPLY, OR IN OTHER WARNING LIGHTS AND INDICATOR LIGHTS

• Do other warning and indicator lights illuminate when the ignition switch is turned to the ON position?

|

Yes

|

Replace the instrument cluster. (open circuit in instrument cluster)

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECT INSTRUMENT CLUSTER POWER SUPPLY FUSE

• Is the instrument cluster ignition power supply fuse normal?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect for a short to ground on circuit of blown fuse.

Repair or replace if necessary.

Install appropriate amperage fuse.

|

||

|

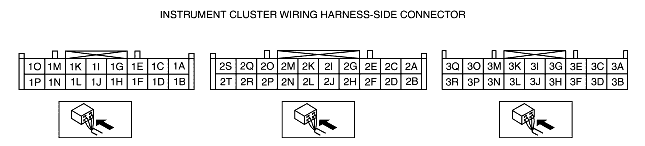

*4 |

VERIFY WHETHER MALFUNCTION IS IN WIRING HARNESS (BETWEEN INSTRUMENT CLUSTER POWER SUPPLY AND INSTRUMENT CLUSTER FOR CONTINUITY) OR INSTRUMENT CLUSTER

• Turn the ignition switch to the ON position.

• Measure voltage at instrument cluster connector terminal 3O.

• Is the voltage approx. 12 V?

|

Yes

|

Replace the instrument cluster (open circuit in instrument cluster).

|

|

No

|

Inspect for open circuit in wiring harness between the instrument cluster and ground.

Repair or replace if necessary.

Replace the ABS HU/CM.

(See ABS HU REMOVAL/INSTALLATION.)

|

||

|

|

|||