Fuel Injector Tip Leakage Test

WARNING: Do not allow smoking or the use of open flames in the area where work on the fuel system is taking place. Anytime the fuel system is being worked on, disconnect the negative battery cable, except for those tests where battery voltage is required.1. Disconnect negative battery terminal.

2. Remove air intake tube and resonator.

WARNING: Whenever fuel line fittings are loosened or disconnected, wrap a shop cloth around fitting while connecting gauge, to collect fuel place the cloth in an approved container.

Fuel System Pressure Relief:

3. Connect fuel gage bar kit (Saturn Tool) SA9127E to fuel pressure test port.

4. Install bleed hose into an approved container and open valve to bleed system pressure.

5. Disconnect the fuel pressure regulator vacuum line.

6. Remove fuel lines from bracket but leave fuel supply lines attached to the fuel rail assembly and connectors. Disconnect return line and plug fuel rail return with plug (Saturn Tool) SA941OE.

WARNING: Lay shop towels on intake - manifold and cam cover to collect any fuel.

WARNING: make sure the injectors are positioned to prevent fuel from being sprayed onto the engine. make sure that the injector retaining clips are properly installed.

Fuel Injector Connections:

7. Remove fuel rail assembly attachment bolts and pull fuel rail back far enough so that the nozzles of the fuel injectors are visible but still in ports. Attach the fuel rail to the intake manifold with safety wire.

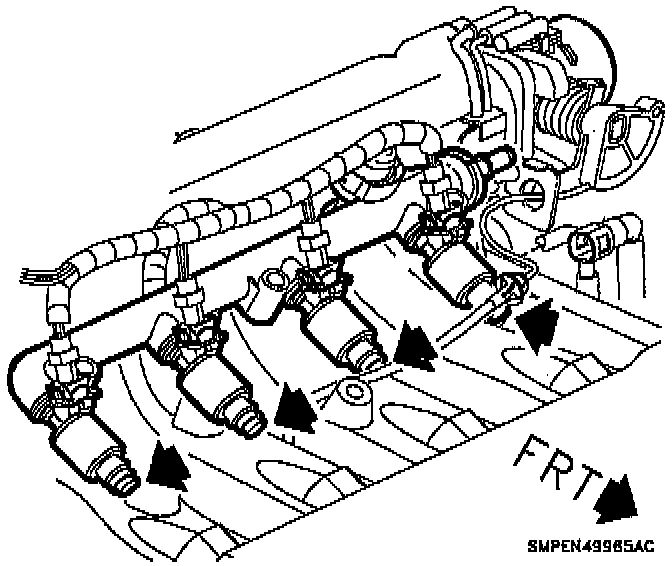

Fuel Injector Tips:

8. Wipe the tips of the fuel injectors free of any fuel or debris and place a clean white towel directly under fuel injector& The clean white towel must lightly contact each fuel injector tip. This will serve as an indicator of leaky fuel injectors by showing spots where fuel has leaked as well as block the injector ports from any debris that might enter. The fuel pressure regulator vacuum must be removed to inspect for full leakage past the diaphragm.

9. Connect negative battery terminal.

NOTE: Battery must be at a minimum of 12 volts when performing a fuel system pressure test.

10. Cycle the ignition key On/Off several times (do not start engine) and observe the fuel injector tips for leakage of fuel. If one or more of the white towels becomes wet with fuel after five minutes, replace the faulty fuel injector. It is very difficult to measure drops of fuel from a injector.

NOTE: Pressure gage reading should be approximately 317 kPa (46 psi) minimum with fuel rail return plugged.

11. Test assembly a minimum of two times.

12. Install bleed hose into an approved container and open valve to bleed system pressure. Once pressure is bled, remove fuel gage adapter from the fuel pressure test port and recap it.

13. Remove the fuel rail return plug.

14. Lubricate injector 0-rings with clean engine oil and install fuel rail assembly.

WARNING: Lubricate steel line male ends with clean engine oil, holding steel line firmly press on female coupler until a click is heard, then pull back to insure a positive engagement. Be sure the fuel line connects are fully seated. pinched, kinked or damaged fuel lines must be replaced.

15. Connect fuel return line connection and pressure regulator vacuum line.

16. Start engine and check for leaks.