P0340

DTC P0340

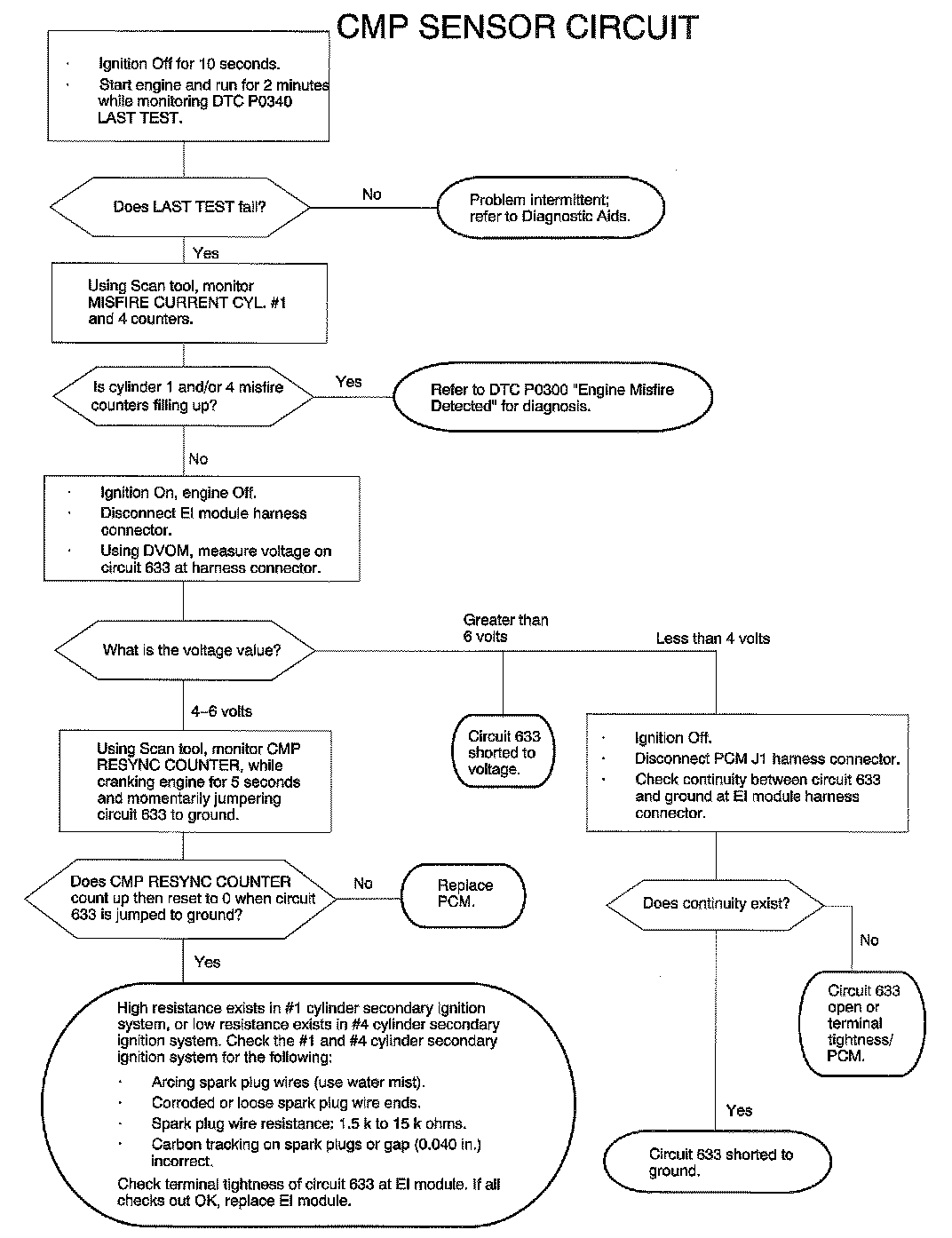

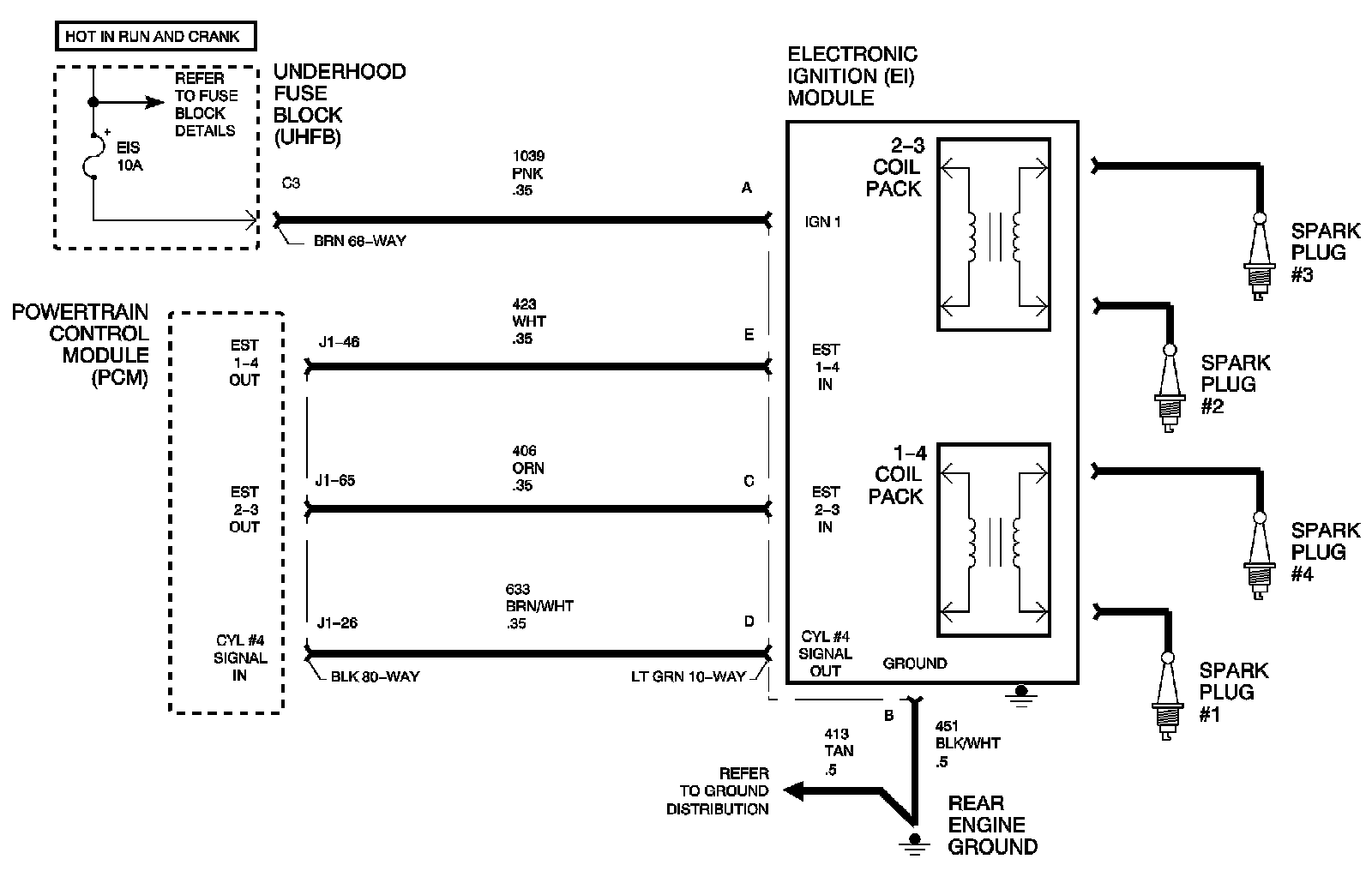

The electronic ignition (EI) module supplies a ground to the cylinder #4 signal wire whenever it determines cylinder #4 has just fired on its compression stroke. The EI module uses capacitive pickup plates located under the 1/4 coil pack to determine the polarity sequence and voltage amplitude of the cylinder 1/4 secondary ignition. The powertrain control module (PCM) supplies 5 volts on the signal line and expects to see the cylinder #4 signal wire go low after every 14 crankshaft pulses (2 revolutions). This is used to determine the position of the camshaft, except under decel. The PCM only uses the transition from 5-0 volts as a valid TDC compression #4 cylinder signal. DTC P0340 sets when the PCM detects missing cam pulses (not seeing one cam pulse every two crankshaft revolutions).

DTC Parameters

DTC P0340 will set if the PCM cam pulse has not been properly detected (cylinder #4 signal line not pulled to ground) for 136 engine revolutions when manifold absolute pressure (MAP) is greater than 30 kPa.

If the PCM detects 20 correct cam pulses in a row, DTC P0340 will pass for the rest of the ignition cycle.

DTC P0340 diagnostic runs continuously until 20 correct cam pulses have been received when the vehicle is not in a decel.

DTC P0340 is a type B DTC.

Diagnostic Aids

Use a scan tool to monitor CMP RESYNC COUNTER while running engine. The counter should count to 14, which indicates the number of notches passed on the crankshaft in 2 revolutions, then reset to zero when a cam pulse is received.

High resistance in the #1 secondary ignition system or low resistance in the #4 secondary ignition system can set this DTC. Check for corroded or loose #1 or #4 secondary ignition components. Use a scan tool to monitor MISFIRE CURRENT CYL #1 and #4 which may point out an intermittent misfire causing the DTC.

A missing cam pulse without a cylinder misfire may not affect engine operation.