Driver Inflator

When a vehicle will be returned to service after replacing a functionally or cosmetically damaged inflator module, perform the deployment procedure outside the vehicle.Before performing the deployment procedure, you should be familiar with SIR service precautions and proper inflator module handling.

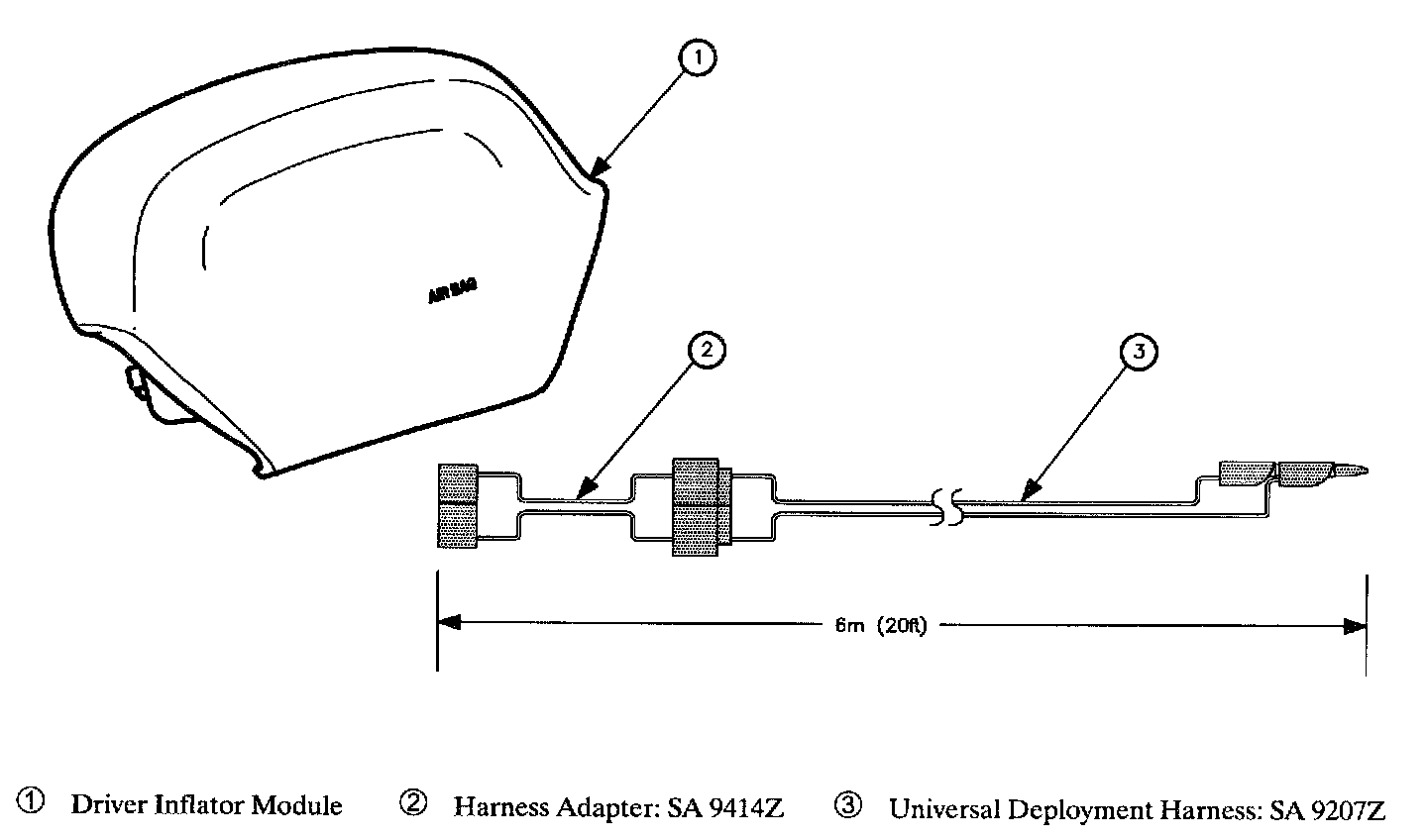

The following procedure requires use of Deployment harness SA92078Z and appropriate harness adapter.

CAUTION: PERFORM THE DEPLOYMENT PROCEDURE IN THE EXACT ORDER LISTED TO AVOID PERSONAL INJURY.

^ WEAR SAFETY GLASSES.

^ SELECT A DEPLOYMENT AREA CLEAR OF PEOPLE, LOOSE OBJECTS AND FLAMMABLE MATERIAL.

1. Short the two universal deployment harness leads together by fully seating one banana plug into the other. Universal deployment harness shall remain shorted and not be connected to a power source until the air bag is to be deployed.

2. Connect the appropriate harness adapter to the universal deployment harness.

3. Remove inflator module from vehicle.

4. Temporarily place the inflator module on a work bench or other surface away from all loose or flammable objects and with its vinyl trim cover facing up.

5. Select a paved outdoor location to perform deployment. Make certain that no loose objects or flammable material are within 4.6 M (15 ft.) of the inflator module.

6. Place inflator module on the ground with the vinyl trim cover facing up.

7. Stretch the universal deployment harness and harness adapter from inflator module to its full length.

8. Place a power source near the shorted end of deployment harness. (Recommended application: 12 Volts minimum, 2 amps minimum. A vehicle battery is suggested.)

9. Connect the SIR inflator module to harness adapter on universal deployment harness.

IMPORTANT: Make sure that harness adapter connector is fully seated into inflator module connector. Failure to fully seat connectors may leave the shorting bar located in the inflator module connector active and may result in non-deployment of inflator module.

10. Verify area around the inflator module is clear of all people, loose objects, or flammable material.

11. Verify inflator module is resting with its vinyl trim cover facing up.

12. Notify all people in the immediate area of your intention to deploy inflator module as the deployment will be accompanied by a substantial noise which may startle the uninformed.

13. Separate the two banana plugs on the universal deployment harness that were shorted together in step 3. Refer to illustration.

IMPORTANT: When air bag deploys, the inflator module may jump approximately one foot in height. This is a normal reaction of inflator module due to the force of rapid gas expansion inside air bag.

14. Connect universal deployment harness wires to power source to immediately deploy inflator module.

15. Disconnect universal deployment harness from power source.

16. Short the two universal deployment harness leads together by fully seating one banana plug into the other.

17. In the unlikely event that inflator module did not deploy after following these procedures, proceed immediately with steps 24 and 25. If the inflator module did deploy, proceed with steps 18 through 23.

CAUTION: IMMEDIATELY FOLLOWING THE DEPLOYMENT OF AN AIR BAG, THE METAL SURFACES OF THE INFLATOR MODULE ARE VERY HOT. DO NOT PLACE THE DEPLOYED INFLATOR MODULE NEAR ANY FLAMMABLE OBJECTS. WAIT FOR ABOUT TEN MINUTES BEFORE TOUCHING ANY METAL SURFACE OF THE INFLATOR MODULE. DISREGARDING THESE PRECAUTIONS MAY CAUSE FIRE OR PERSONAL INJURY.

After an inflator module has been deployed, the metal canister and surrounding areas of the inflator module will be very hot. Do not touch metal areas of inflator module for about 10 minutes after deployment. If deployed inflator module must be moved before it is cool, wear gloves and handle by air bag or vinyl trim.

After inflator module has been deployed, the surface of the air bag may contain a powdery residue. This powder consists primarily of corn starch (used to prevent bag from adhering to itself over the life of the product) and by-products of the chemical reaction. Sodium hydroxide dust (similar to lye soap) is produced as a by-product of the deployment reaction. The sodium hydroxide then quickly reacts with the atmospheric moisture and is converted to sodium carbonate and sodium bicarbonate (baking soda). Therefore, it is unlikely that sodium hydroxide will be present after deployment. As a precaution, however, gloves and safety glasses are recommended to prevent any possible irritation of the skin or eyes.

18. Put on a pair of shop gloves to protect your hands from possible irritation and heat when handling deployed inflator module. Safety glasses should also be worn to protect your eyes.

19. Disconnect harness adapter from inflator module as soon after deployment as possible to avoid the possibility of damage to harness adapter or universal deployment harness due to possible contact with the hot inflator module canister. The universal deployment harness is designed to be reused. It should, however, be inspected for damage after each deployment and replaced if necessary. The harness adapter, SA9414Z, may become damaged because of high temperatures and should be discarded after deployment outside vehicle.

20. Dispose of deployed inflator module through normal refuse channels after it has cooled for at least 10 minutes.

21. Wash your hands with mild soap and water afterward.

IMPORTANT: The remaining steps are to be followed in the unlikely event that the inflator module did not deploy after following these procedures.

22. Make certain universal deployment harness has been disconnected from power source and that its two banana plugs have been shorted together by fully seating one banana plug into the other.

23. Disconnect harness adapter from inflator module.

CAUTION: WHEN YOU ARE CARRYING AN UNDEPLOYED INFLATOR MODULE:

^ DO NOT CARRY THE INFLATOR MODULE BY THE WIRES OR CONNECTOR ON THE INFLATOR MODULE.

^ MAKE SURE THE BAG OPENING POINTS AWAY FROM YOU.

WHEN YOU ARE STORING AN UNDEPLOYED INFLATOR MODULE, MAKE SURE THE BAG OPENING POINTS AWAY FROM THE SURFACE ON WHICH THE INFLATOR MODULE RESTS. WHEN YOU ARE STORING A STEERING COLUMN, DO NOT REST THE COLUMN WITH THE BAG OPENING FACING DOWN AND THE COLUMN VERTICAL. PROVIDE FREE SPACE FOR THE AIR BAG TO EXPAND IN CASE OF AN ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL INJURY MAY RESULT.

24. Temporarily store inflator module with its soft vinyl trim cover facing up, away from the surface on which it rests.

25. Call the Saturn Technical Assistance Center for further instruction on disposal.