Installation

INSTALLATION1. Install cooling module support grommets into frame.

NOTICE: Make sure that the following parts are correctly positioned when raising frame into vehicle:

^ Lower corner arm ball studs to knuckle.

^ Cooling module support grommets.

^ Engine strut frame bracket.

^ Transaxle mount.

2. Using a powertrain support dolly, carefully position frame into vehicle.

3. Install two rear frame-to-body fasteners.

IMPORTANT: Do not tighten fastener at this time.

4. Position frame to body at the two front frame alignment holes using a 9/16 inch rod and install fasteners.

IMPORTANT: Check frame to body alignment after tightening. If alignment is not correct, loosen fastener, align frame and tighten.

5. Tighten four frame-to-body fasteners.

Torque: Frame-to-Body Fastener: 205 Nm (151 ft. lbs.)

6. Remove powertrain support dolly.

7. Lower vehicle enough to allow underhood access and remove engine support bar.

8. Install transaxle strut-to-midrail bolt.

Torque: Transaxle-Strut-to-Midrail Bolt: 70 Nm (52 ft. lbs.)

9. Remove cooling module support wire.

10. Install air box with three fasteners.

Torque: Air Box Fastener: 10 Nm (89 inch lbs.)

11. Install resonator and secure with plastic push pin.

12. Connect electrical connector at the Intake Air Temperature (IAT) sensor.

13. Install air cleaner housing cover and clean air inlet tube.

14. Connect fresh air hose at cam cover.

15. Secure clamp at throttle body assembly.

CAUTION: MAKE SURE VEHICLE IS PROPERLY SUPPORTED AND SQUARELY POSITIONED ON HOIST. TO HELP AVOID PERSONAL INJURY, PROVIDE ADDITIONAL SUPPORT TO THE OPPOSITE END OF THE VEHICLE THAT COMPONENTS WILL BE REMOVED FROM.

16. Raise vehicle on hoist.

17. Install a new transaxle mount-to-frame fastener.

18. Tighten transaxle strut frame bracket-to-frame nut.

Torque: Transaxle Strut Frame Bracket-to-Frame Nut: 50 Nm (37 ft. lbs.)

19. Install new engine strut bracket-to-frame fasteners.

Torque: Engine Strut Bracket-to-Frame Nuts: 50 Nm (37 ft. lbs.)

20. Remove steering gear support wire.

21. Install steering gear-to-frame attachment bolts and new nuts (power steering gear shown, manual steering gear similar).

Torque: Steering Gear-to-Frame Fasteners: 50 Nm (37 ft. lbs.)

22. Attach brake pipe bracket to rear of frame with fastener (ABS brake shown, base similar).

IMPORTANT: Lower control arm ball stud threads must be thoroughly cleaned and lubricated before tightening nut.

23. Install ball joint stud castle nuts and install new cotter pins.

Torque: Ball Joint Stud Castle Nut: 75 Nm (55 ft. lbs.)

IMPORTANT: Do not loosen nut to align slot in castle nut with hole in stud. Always tighten nut when necessary to install cotter pin.

24. Install new cotter pin.

25. Position front exhaust pipe into vehicle.

26. Install front exhaust pipe-to-exhaust manifold fasteners and tighten.

Torque: Front Exhaust Pipe-to-Exhaust Manifold Fasteners: 31 Nm (23 ft. lbs.)

27. Install front exhaust Pipe-to-Catalytic converter fasteners.

Torque: Front Exhaust Pipe-to-Catalytic Converter Fasteners: 25 Nm (19 ft. lbs.)

28. Install front exhaust pipe isolators.

29. Install front air dam onto vehicle.

30. For coupes, install right and left lower fascia brace-to-frame J-nuts.

Torque: Lower Fascia Brace-to-Frame J-Nuts: 10 Nm (89 inch lbs.)

31. For coupes, install right and left lower fascia braces with fasteners.

Torque: Lower Fascia Brace with Fastener: 10 Nm (89 inch lbs.)

IMPORTANT: For left side, install rear section of shield first, then front. For right side, install front section of shield first, then rear.

32. Install left and right side splash shields.

33. Install tabs in body cut-out.

IMPORTANT: Make sure shield flaps are tucked in at body locations.

34. Align molded-in shield fasteners with holes in frame. Push straight in to install.

35. Install push pins.

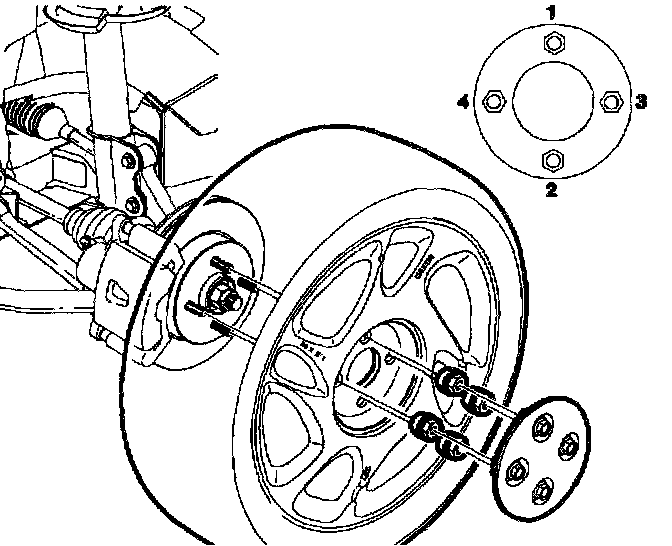

NOTICE: Before installing wheels, remove rust or corrosion from wheel mounting surfaces and brake rotors/drums. Failure to do so can cause wheel nuts to loosen in service.

36. Position wheel onto hub.

37. Install wheel nuts and tighten in a crisscross pattern. Repeat tightening pattern to ensure torque is correct.

Torque: Wheel Nuts: 140 Nm (103 ft. lbs.)

38. Lower vehicle from hoist.

39. Perform vehicle alignment.