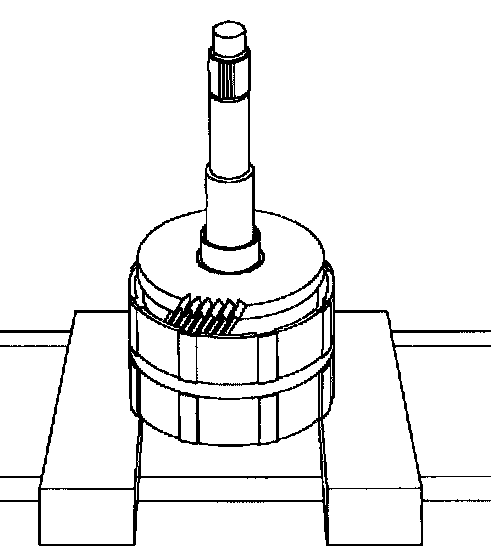

7. Input Shaft

TOOLS REQUIRED

- SA9143T Input Shaft Seal Installer

- SA9144T Input Shaft Teflon Ring Set

NOTICE: Prior to using Input Shaft Seal Installer SA9143T or Input Shaft Seal Ring Set SA9144T, inspect tools for any nicks or burrs that could damage input shaft seals.

IMPORTANT: Lube seals with Saturn Transaxle Fluid.

1. Install input shaft seals using input shaft seal installer and input shaft Teflon ring set.

Installer - Input Shaft Seal Installer SA9143T

Expanders: Input Shaft Teflon Ring Set SA9144T

1st - Ring Expander (Long) SA9144T-2

2nd - Ring Expander (Medium) SA9144T-3

3rd - Ring Expander (Short) SA9144T-4

Ring Sizer- SA9144T-1

Install seals by first placing seals on expander and then using pusher.

2. Size seals using Ring Sizer SA9144T-1. Use seal sizer by rotating the tool and pushing lightly one seal at a time until all three have been sized.

3. Install stator shaft needle bearing assembly.

4. Install input shaft to converter O-ring.

IMPORTANT: Lube O-rings with Saturn Transaxle Fluid.

5. Lube and install the three O-ring clutch seals in grooves on shaft.

6. Install 2nd/Rev and 3rd clutch hub thrust washer onto 2/3 clutch housing. Washer goes on 3rd gear side of housing which is smaller. Make sure slots on washer line up with tangs.

7. Install thrust bearing in 3rd gear hub using petroleum jelly to help hold in place.

8. Install 3rd gear in clutch housing by twisting the gear to align the gear hub with the clutch tangs.

While installing into the clutch pack, rotate the gear and hub assembly back and forth to align the clutch plates. If you are not sure that all the clutch plates have been engaged, lift the gear out of the clutch housing and verify that all clutch tangs are aligned.

9. Lube and install 3rd drive gear bearing assembly into 3rd gear.

10. Install thrust bearing on 3rd gear.

NOTICE: To verify repair and installation of 2nd/3rd clutch seals, air check input shaft.

11. Install shaft down through 3rd gear and clutch assembly previously assembled. Use a twisting motion to line up splines. Be sure 3rd gear fits all the way against 4th gear.

12. Install the 2nd/Reverse drive gear thrust washer. The washer has an internal tang that lines up with lube slot on shaft.

13. Using a heat gun, heat the 2nd/Reverse gear needle bearing race and install race. The race can also be pressed on using tool SA9118T, but be sure to put press support under the gear that is part of the input shaft.

14. Install the 2nd/Reverse gear thrust bearing.

IMPORTANT: The 2nd/Reverse gear thrust bearing looks similar to the 4th gear thrust bearing. However, the 2nd/Reverse thrust bearing is slightly larger than the 4th gear thrust bearing. Also, the rollers on the 2nd/Reverse thrust bearing are located closer to the outside edge of the bearing while the rollers on the 4th gear thrust bearing are centered between the inner and outer edges of the bearing.

15. Lube and install the 2nd/Reverse gear bearing assembly.

16. Install the 2nd/Reverse gear, twist the gear to align the clutch tangs.

While installing the clutch pack, rotate the gear and hub assembly back and forth to align the clutch plates. If you are not sure that all the clutch plates have been engaged, lift the gear out of the clutch housing and verify that all clutch tangs are aligned.

17. Install the 2nd/Reverse thrust bearing with tab side of bearing toward gear.