Cylinder Liner: Service and Repair

Cylinder Sleeve Replacement

Tools Required

EN 45680-850 Cylinder Sleeve Removal and Installation Kit

Removal Procedure

Notice: Do not chill or heat the cylinder bore sleeve or the cylinder block when removing or installing a new cylinder bore sleeve. Chilling or heating the cylinder bore sleeve or the cylinder block will cause engine damage and will not aid the removal or installation of the new cylinder bore sleeve.

Notice: Do not damage the crankshaft connecting rod journals or reluctor ring or engine damage will occur.

1. Remove the cylinder head.

2. Remove the oil pan.

3. Remove the piston and connecting rod.

4. Inspect the condition of the piston.

5. Rotate the crankshaft so that the counterweight is to the right side and the connecting rod journal is to the left side and not in alignment with the cylinder bore.

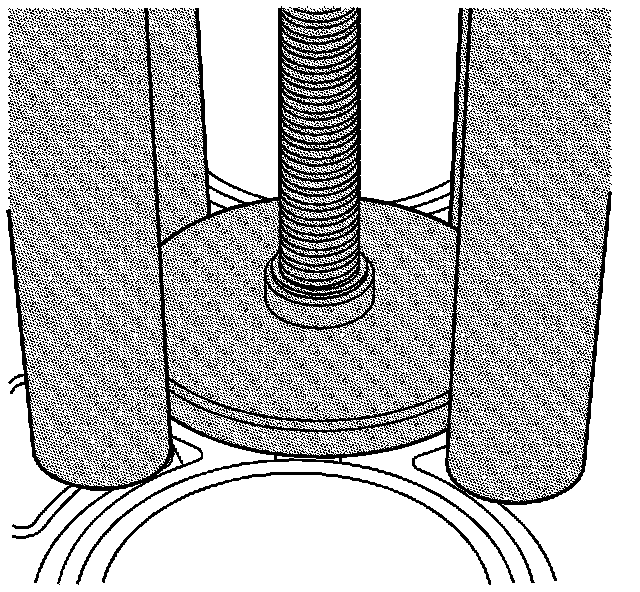

6. Install the EN 45680-852 cylinder bore sleeve puller (1) through the cylinder bore.

Notice: Ensure that the shoe is flat against the bottom of the cylinder bore liner or damage to the cylinder bore liner puller EN45680-852 will occur.

7. Align the shoe (1) of the EN 45680-852 cylinder bore sleeve puller to the bottom of the cylinder bore sleeve (2).

8. Hold the threaded shaft of the EN 45680-852 cylinder bore sleeve puller upward in order to retain the shoe alignment to the bottom of the cylinder bore sleeve.

9. Install the EN 456850-851 fixture (4) onto the threaded shaft of the EN 456850-852 cylinder bore sleeve puller and the engine block.

10. Install the bearing (3) and the nut (1).

11. Tighten the nut (1) to the bearing (3).

Notice: Refer to Fastener Notice.

Important: Use 4 old cylinder head bolts for the attaching bolts.

12. Install and tighten the 4 attaching bolts (2) into the cylinder head bolt holes of the block.

Tighten the bolts to 15 N.m (11 lb ft).

13. Rotate the nut clockwise in order to remove the cylinder bore liner.

Notice: Do not damage the cylinder block surface. Damage to the cylinder block surface can cause engine failure.

14. Remove EN 45680-851 fixture, EN 45680-852 cylinder bore sleeve puller, and the cylinder bore sleeve from the engine block.

15. Inspect the cylinder bore in the cylinder block for cracks or damage. If cracked or damaged, replace the cylinder block.

Installation Procedure

Notice: Do not use assembly aids or lubricants on the cylinder bore sleeve or the cylinder bore block when installing a new cylinder bore sleeve, or engine damage will occur. These items will not aid in the installation of the new cylinder bore sleeve.

Notice: Do not chill or heat the cylinder bore sleeve or the cylinder block when removing or installing a new cylinder bore sleeve. Chilling or heating the cylinder bore sleeve or the cylinder block will cause engine damage and will not aid the removal or installation of the new cylinder bore sleeve.

1. Place the NEW cylinder bore sleeve onto the cylinder block.

2. Install EN 45680-851 fixture and EN 45680-853 cylinder bore sleeve installer assembly over the cylinder bore sleeve and onto the cylinder block. Do not apply downward pressure to the cylinder bore sleeve.

Notice: Refer to Fastener Notice.

Important: Use 4 old cylinder head bolts for the attaching bolts.

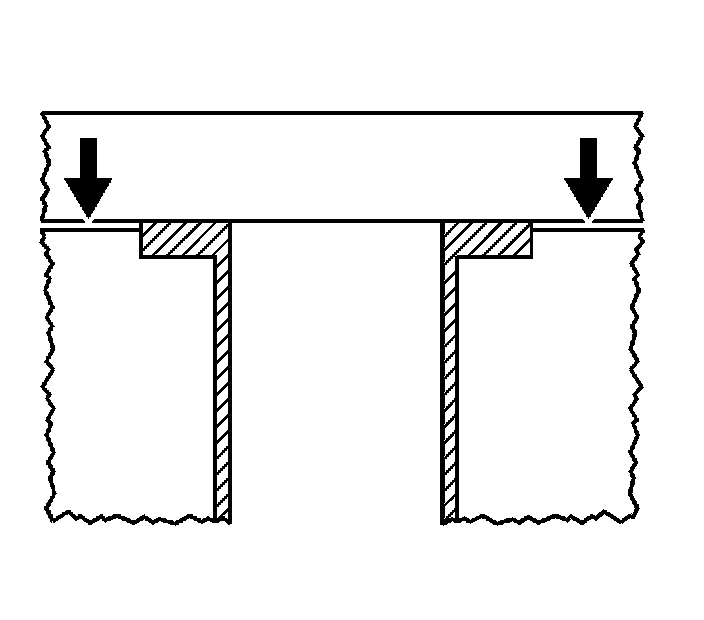

3. Insert the 4 attachment bolts into the legs of the EN 45680-851 fixture (1). Do not apply downward pressure to the cylinder bore sleeve (2).

Tighten the 4 attachment bolts to 15 N.m (11 lb ft).

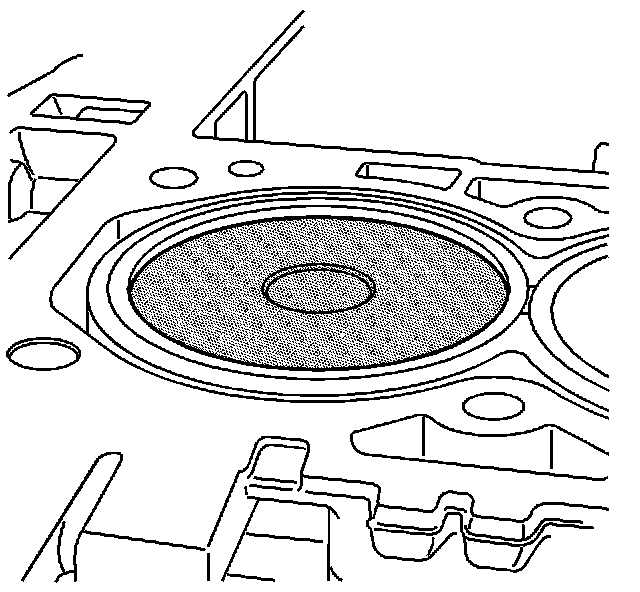

4. Align the bottom of the cylinder bore sleeve (1) with the cylinder bore of the block (2).

5. Align the installation arbor (1) onto the top of the cylinder bore sleeve (2).

6. Align the pusher block (2) of EN 45680-853 cylinder bore sleeve installer into the groove of EN 45680-851 fixture (1).

Notice: Do not use any air powered or electric tools to rotate the threaded shaft of the fixture EN 45680-851/cylinder bore liner installer EN 45680-853 assembly or damage to the cylinder bore liner will occur.

7. Using a ratchet, rotate the threaded shaft of EN 45680-85 fixture and EN 45680-853 cylinder bore sleeve installer assembly in order to install the cylinder bore sleeve into the engine block.

8. Do not completely seat the cylinder bore sleeve in the block. Leave approximately 1/16 inch of the cylinder bore sleeve above the surface of the cylinder block.

9. Using a torque wrench, tighten the threaded shaft of the EN 45680-851 fixture and EN 45680-853 cylinder bore sleeve installer assembly to 102 N.m (75 lb ft) in order to completely seat the cylinder bore sleeve in the cylinder block. With the cylinder bore sleeve properly installed, a minimal portion of the cylinder bore liner flange will protrude above the block deck surface.

10. Remove the EN 45680-851 fixture and EN 45680-853 cylinder bore sleeve installer assembly (1) from the cylinder block (2).

Cylinder Liner Trimming

* EN 45680-865 Debris Collector (3)

* EN 45680-861 Trim Tool Assembly (2)

* Air Control Valve (1)

* Drill Motor with 1/2 inch chuck, 1 1/8 hp, 7 amps, triple gear reduction, and a 450-600 RPM rotational speed in a clockwise direction

* Trim Tool Preloader (1)

* EN 45680-862 Set Gage Ring (2)

* EN 45680-863 Metal Shavings Catch Plug (3)

* EN 45680-866 Drive Adapter (4)

* EN 45680-864 Bolts (5)

Notice: Do not bore or hone the cylinder bore sleeve. The cylinder bore sleeve inside diameter (I.D) is fully machined and honed to size and is optimally finished as shipped. Any attempt to modify this factory-produced sizing and finish with additional boring and honing will lead to engine damage, excessive noise or abnormal oil consumption.

1. After installing the NEW cylinder bore sleeve(s) into the engine block, trim the excess material from the cylinder bore sleeve flange.

Notice: Ensure that all the metal particles are collected in order to prevent internal damage to the transaxle or bearings.

2. Place the EN 45680-863 metal shaving catch plug into the cylinder bore sleeve to be trimmed. Position the top of the EN 45680-863 approximately 3.0 mm (0.12 in) below the top surface of the cylinder bore sleeve.

3. Place additional EN 45680-863 metal shaving catch plugs into all remaining cylinder bore sleeves.

Notice: Installing the metal shaving catch plug EN 45680-863 deeper than the recommended depth will create a decrease in vacuum system performance. A decrease in vacuum system performance will cause metal shavings to enter the engine and cause engine failure.

Notice: Installing the metal shaving catch plug EN 45680-863 above the recommended depth will cause damage to the metal shaving catch plug EN 45680-863.

4. Ensure that the EN 45680-863 metal shaving catch plug is 3.0 mm (0.12 in) below the top surface of the cylinder bore sleeve.

Important: Before using EN 45680-861 trim tool assembly, the height of the cutting blades must be set to the proper specification. The proper specification is that the cylinder bore sleeve flange must be flush to +0.02 mm (0.0008 in) above the block deck surface.

5. The groove side of the EN 45680-862 set gage ring (1) should be positioned upward on a flat surface.

Important: Ensure that the EN 45680-862 set gage ring surfaces are clean.

6. Carefully position EN 45680-861 trim tool assembly onto the EN 45680-862 set gage ring.

7. Loosen the shaft collar screw (2).

8. Push the shaft collar (2) downward using the trim tool preloader (1) until the shaft collar is positioned against the top of the flange bearing (3).

Important: Once this procedure is done, it is not necessary to reset the EN 45680-861trim tool assembly height until the blades are worn or damaged.

9. Apply downward pressure on the collar and inner drive shaft using the trim tool preloader (1), then tighten the shaft collar screw.

Tighten the shaft collar screw to 19 N.m (14 lb ft).

10. Place the EN 45680-861 trim tool assembly onto the cylinder to be trimmed with the directional arrow pointing in line with the crankshaft centerline and the front of the block.

11. Install the EN 45680-864 4 bolts into the cylinder head bolt holes in the block.

Tighten the bolts to 20 N.m (15 lb ft).

Notice: For proper tool operation, a drill motor with a 1/2 inch chuck, 1 1/8 hp, 7 amps, triple gear reduction, and a 450-600 RPM rotational speed in a clockwise direction must be used. If the proper drill motor is not used, damage to the cylinder bore sleeve will occur.

12. Fasten the drive adapter EN 45680-866 into the drill chuck.

Notice: Ensure that there are no crimps in the air feed hose or the vacuum hose. Crimps in the hose may cause metal shavings to exit the cutting tool in any direction, causing engine damage.

13. Connect a compressed air supply (75-125 psi) to the male quick connect located on EN 45680-861 trim tool assembly. Turn the compressed air valve to the open position. This starts the venturi vacuum system that will catch the metal shavings.

14. Place the EN 45680-866 drive adapter and the drill assembly vertically onto the EN 45680-861 drive adapter end of trim tool assembly. Do not apply downward force on the drill until full rotational speed has been reached. After reaching full rotational speed, gradually apply downward force until the cutting action is complete in approximately 5 seconds.

15. Remove the EN 45680-866 drive adapter (1) and the drill assembly from the EN 45680-861 trim tool assembly.

16. Turn OFF the compressed air valve.

17. Remove the EN 45680-861 trim tool assembly from the engine block.

18. Wipe the cylinder bore sleeve and the surrounding areas of any powder residue. Remove the EN 45680-863 metal shaving catch plug.

19. Install a straight edge on the cylinder block perpendicular to the crankshaft centerline.

20. Using a light, illuminate the backside of the straight edge.

21. Looking at the front of the straight edge, inspect to see if light is protruding through the bottom of the straight edge and the top of the cylinder bore sleeve flange. If light is present on either side of both sides of the cylinder bore sleeve, the cylinder bore sleeve is cut incorrectly and a new cylinder bore sleeve needs to be installed.

22. Looking at the front of the straight edge, inspect to see if light is protruding through the bottom of the straight edge and the top of the cylinder block deck surface. If light is present on both sides of the cylinder block, the cylinder bore sleeve is cut correctly.

23. Proceed to the next bore sleeve to be trimmed, repeating steps 10-19 if necessary.

24. Install the piston and the connecting rod.

25. Install the oil pan.

26. Install the cylinder head.