Reassembly

FA20 ENGINE MECHANICAL: CYLINDER BLOCK: REASSEMBLY; 2013 MY FR-S [03/2012 -]

1. INSTALL NO. 1 CYLINDER BLOCK TIGHT PLUG

NOTICE:

* Place wooden blocks wrapped in a cloth under the cylinder block and stabilize the cylinder block during servicing.

* Place a cloth to avoid scratching the mating surface of the cylinder block during servicing.

(a) Apply seal packing to the threaded portion of the No. 1 cylinder block tight plugs and install them to the cylinder block (for bank 1) and cylinder block (for bank 2).

Seal packing:

Three Bond 1105 or equivalent

Torque : 37 Nm (377 kgf-cm, 27 ft-lbf)

NOTICE:

Before applying seal packing, degrease the No. 1 cylinder block tight plugs and thread holes of the cylinder block (for bank 1) and cylinder block (for bank 2).

2. INSTALL CRANKSHAFT SENSOR HOLDER ASSEMBLY

(a) Install the crankshaft sensor holder assembly to the cylinder block (for bank 2) with the 2 bolts.

Torque : 6.4 Nm (65 kgf-cm, 57 in-lbf)

3. INSTALL CYLINDER BLOCK PLATE

(a) Install the cylinder block plate to the cylinder block (for bank 2) with the 5 bolts.

Torque : 6.4 Nm (65 kgf-cm, 57 in-lbf)

4. INSTALL OIL SEPARATOR COVER

(a) Apply seal packing in a continuous line as shown in the illustration.

Seal packing:

Three Bond 1217G or equivalent

NOTICE:

* Clean and degrease the contact surface.

* Install the oil separator cover within 5 minutes of applying seal packing.

(b) Tight the 7 bolts in the order shown in the illustration to install the oil separator cover to the cylinder block (for bank 1).

Torque : 6.4 Nm (65 kgf-cm, 57 in-lbf)

5. INSTALL O-RING

(a) Attach a new O-ring to the cylinder block (for bank 2).

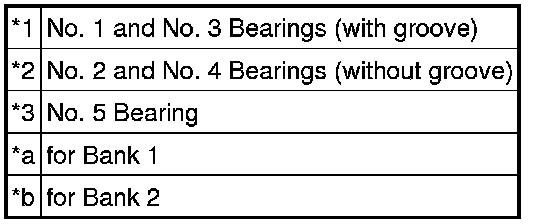

6. INSTALL CRANKSHAFT BEARING

(a) Apply engine oil to the crankshaft bearing, and install them to the cylinder block (for bank 1) and cylinder block (for bank 2).

NOTICE:

* Place a cloth to avoid scratching the mating surface of the cylinder block during servicing.

* The shapes of the No. 1 and No. 3 bearings are different from those of the No. 2 and No. 4 bearings. Be sure to install them in the right locations.

7. INSTALL CRANKSHAFT

(a) Apply engine oil to the crankshaft journals and place the crankshaft on the cylinder block (for bank 2).

8. INSTALL CYLINDER BLOCK SUB-ASSEMBLY (for Bank 1)

(a) Apply seal packing to the mating surface of the cylinder block sub-assembly (for bank 1) as shown in the illustration.

Seal packing:

Three Bond 1217G or equivalent

NOTICE:

* Do not let the seal packing overflow to the oil passage or crankshaft bearing because engine seizure may result.

* Clean and degrease the contact surface.

* Install the cylinder block sub-assembly (for bank 1) within 5 minutes of applying seal packing.

(b) Place the cylinder block sub-assembly (for bank 1) to the cylinder block sub-assembly (for bank 2).

(c) Apply engine oil to the washers and cylinder block bolt threads.

NOTICE:

To prevent engine oil from entering into the water jacket, do not apply a large amount.

(d) Using a 12 mm socket wrench, tighten the 10 bolts in the order shown in the illustration.

Torque : 35 Nm (357 kgf-cm, 26 ft-lbf)

NOTICE:

When tightening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(e) Using a 12 mm socket wrench, loosen the 10 bolts by 180 ° in the order shown in the illustration.

NOTICE:

When loosening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(f) Using a 12 mm socket wrench, tighten the 10 bolts in the order shown in the illustration.

Torque : 35 Nm (357 kgf-cm, 26 ft-lbf)

NOTICE:

When tightening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(g) Using a 12 mm socket wrench, loosen the 4 bolts by 180 ° in the order shown in the illustration.

NOTICE:

When loosening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(h) Using a 12 mm socket wrench, tighten the 4 bolts in the order shown in the illustration.

Torque : 17 Nm (173 kgf-cm, 13 ft-lbf)

NOTICE:

When tightening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(i) Using a 12 mm socket wrench and an angle gauge, tighten the 4 bolts by additional 60° in the order shown in the illustration.

NOTICE:

When tightening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(j) Using a 12 mm socket wrench, loosen the 6 bolts by 180 ° in the order shown in the illustration.

NOTICE:

When loosening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(k) Using a 12 mm socket wrench, tighten the 6 bolts in the order shown in the illustration.

Torque : 17 Nm (173 kgf-cm, 13 ft-lbf)

NOTICE:

When tightening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(l) Using a 12 mm socket wrench and an angle gauge, tighten the 6 bolts by additional 60° in the order shown in the illustration.

NOTICE:

When tightening the bolts, hold the cylinder block sub-assembly (for bank 2) while not holding the cylinder block sub-assembly (for bank 1) to ensure the joint accuracy of the cylinder blocks.

(m) Tighten the 5 bolts.

Torque : 25 Nm (255 kgf-cm, 18 ft-lbf)

HINT

After tightening, if the seal packing is squeezed out in the seal surface area of the chain cover and oil pan sub-assembly, completely remove it. Seal packing on the chamfer area, however, should not be removed.

(n) Check that the crankshaft turns smoothly.

9. INSTALL REAR ENGINE OIL SEAL

(a) Apply a light coat of engine oil to a new rear engine oil seal inner periphery and outer periphery.

(b) Using SST and a hammer, tap in the rear engine oil seal uniformly to the position shown in the illustration.

SST : 09223-15030

SST : 09950-70010

09951-07150

Oil seal tap-in depth:

0 to 1.0 mm (0 to 0.039 in.) from the cylinder block surface

NOTICE:

* Do not tap in the rear engine oil seal at an angle.

* Remove the engine oil from the crankshaft.

* Do not tap in the rear engine oil seal more than necessary.

10. INSTALL CYLINDER BLOCK SUB-ASSEMBLY

(a) Mount the cylinder block sub-assembly onto an engine stand.

11. INSTALL PISTON WITH PIN SUB-ASSEMBLY

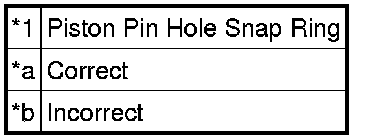

(a) Using a screwdriver with its tip wrapped in protective tape, install the piston pin hole snap ring on one end of the piston.

HINT

* Make sure that the piston pin hole snap ring is firmly attached into the piston pin hole snap ring groove.

* After installing the piston pin hole snap ring, rotate the piston pin hole snap ring so that its end part and the cutout portion of the piston pin hole snap ring groove do not match.

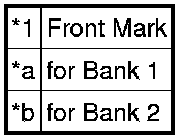

(b) Make sure the directions of the piston front mark and connecting rod, and then set the piston to the connecting rod.

(c) Apply engine oil to the piston pin and install it to the piston.

(d) Using a screwdriver with its tip wrapped in protective tape, install the piston pin hole snap ring to the piston.

HINT

* Make sure the piston pin hole snap ring is firmly attached into the piston pin hole snap ring groove.

* After installing the piston pin hole snap ring, rotate the piston pin hole snap ring so that its end part and the cutout portion of the piston pin hole snap ring groove do not match.

12. INSTALL PISTON RING SET

(a) Install the oil ring expander, lower oil ring side rail and upper oil ring side rail in order by hand.

HINT

The oil ring consists of the 2 oil ring side rails and oil ring expander.

(b) Set the oil ring expander ends at the location B in the illustration.

(c) Hook the stoppers at the both ends of the lower oil ring side rail into the oil return hole at the coating cutout portion A and the oil ring expander as shown in the illustration.

(d) Align the rail ends of the upper oil ring side rail within the range C and hook the stopper into the oil ring expander.

(e) Using a piston ring expander, install the No. 2 compression ring and No. 1 compression ring in order.

(f) Set the No. 1 compression ring ends at the location A or B in the illustration.

HINT

The No. 1 compression ring ends can be set either at A or B.

(g) Set the No. 2 compression ring ends at the location A or B, that is 180° opposite of those of the No. 1 compression ring.

(h) Check that the piston rings and oil rings are correctly set.

13. INSTALL PISTON SUB-ASSEMBLY WITH CONNECTING ROD

(a) Operate the engine stand so that the oil pan side faces upward.

(b) Install the connecting rod bearings to the connecting rod and connecting rod cap. [*1]

(c) Check that the piston rings and oil rings are correctly set.

(d) Apply engine oil to the piston and inside the cylinder bore.

(e) Turn the crankshaft so that the crank pin is positioned at TDC.

(f) Squeeze the piston rings with a piston ring compressor, face the piston front mark toward the engine front side, and insert the piston with connecting rod into the cylinder block by lightly tapping on the piston top with a hammer handle, etc.

NOTICE:

* When inserting the piston with connecting rod, be careful not to scratch the cylinder bore or crank pin by connecting the rod edge.

* Be careful not to apply too much impact when inserting to prevent the connecting rod bearing from falling off.

(g) Apply engine oil to the seating face of the connecting rod cap and threads of the connecting rod cap bolts.

(h) While pushing the piston top, turn the crankshaft to position the crankshaft pin and connecting rod large end as shown in the illustration, and then attach the connecting rod cup with 2 new connecting rod cap bolts.

HINT

* Each connecting rod has its own mating cap. Make sure that they are assembled correctly by checking their matching symbols.

* Use new connecting rod cap bolts.

* Turn the crankshaft counterclockwise when installing the No. 1 or No. 3 piston with connecting rod, and turn the crankshaft clockwise when installing the No. 2 or No. 4 piston with connecting rod.

(i) Using a "TORX" socket wrench E14, tighten the 2 connecting rod cup bolts in the order shown in the illustration.

Torque : 10 Nm (102 kgf-cm, 7 ft-lbf)

(j) Retighten the 2 connecting rod cup bolts in the same order as above. [*2]

Torque : 25 Nm (255 kgf-cm, 18 ft-lbf)

(k) In the same procedures from [*1] to [*2], install the No. 2, No. 3 and No. 4 piston with connecting rods.

(l) Using a "TORX" socket wrench E14 and an angle gauge, tighten the connecting rod cup bolts for the No. 1 to No. 4 piston with connecting rods by additional 92.5°.

(m) Check that the crankshaft can be turned smoothly.