Repair

FA20 ENGINE MECHANICAL: CYLINDER HEAD: REPAIR; 2013 MY FR-S [03/2012 -]

1. REPAIR INTAKE VALVE SEATS

NOTICE:

* Repair the seat while checking the seating position.

* Releasing the seat cutter pressure gradually helps to make the intake valve seat faces smoother.

(a) Using a 45° cutter, resurface the valve seat so that the valve seat width is more than the specification.

(b) Hand-lap the valve and valve seat with an abrasive compound.

(c) Check the valve seating position.

HINT

This procedure is necessary to select a cutter to be used in the following steps.

(d) Using 30° or 75° cutters, correct the valve seat so that the contact condition between the valve and valve seat is within the standard.

NOTICE:

* Repair the seat while checking the seating position.

* Releasing the seat cutter pressure gradually helps to make the intake valve seat faces smoother.

HINT

Select an appropriate cutter by referring to the following chart.

(e) Hand-lap the valve and valve seat with an abrasive compound.

2. REPAIR EXHAUST VALVE SEATS

NOTICE:

* Repair the seat while checking the seating position.

* Releasing the seat cutter pressure gradually helps to make the intake valve seat faces smoother.

(a) Using a 45° cutter, resurface the valve seat so that the valve seat width is more than the specification.

(b) Hand-lap the valve and valve seat with an abrasive compound.

(c) Check the valve seating position.

HINT

This procedure is necessary to select a cutter to be used in the following steps.

(d) Using 30° or 60° cutters, correct the valve seat so that the contact condition between the valve and valve seat is within the standard.

NOTICE:

* Repair the seat while checking the seating position.

* Releasing the seat cutter pressure gradually helps to make the intake valve seat faces smoother.

HINT

Select an appropriate cutter by referring to the following chart.

(e) Hand-lap the valve and valve seat with an abrasive compound.

3. REPAIR VALVE

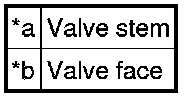

(a) Apply a light layer of engine oil to the valve stem, and a small amount of an abrasive compound uniformly to the valve face.

HINT

* Do not apply the abrasive compound more than necessary.

* Do not apply the abrasive compound to the valve stem as the valve stem may be affected.

(b) Slowly insert the valve stem into the valve guide bush and lap the valve and valve seat.

HINT

* Lift the valve and strike the valve on the valve seat 2 times, and slightly rotate the valve. Repeat this set.

* The contact surface between the valve and the valve seat may become larger than the standard value, therefore, ensure that the valve is not continuously lapped by rotating while seated in the valve seat.

* While lapping, ensure that the valve is not removed from the valve guide bush by lifting too much.

(c) After lapping, completely remove the abrasive compound.

NOTICE:

Be sure to completely remove the abrasive compound as the remained compound could cause engine troubles.

(d) Check the valve seating position and width.