Fuel Pump Control Circuit

FA20 ENGINE CONTROL: SFI SYSTEM: Fuel Pump Control Circuit; 2013 MY FR-S [03/2012 -]

- Fuel Pump Control Circuit

DESCRIPTION

The fuel pump circuit (low pressure side) is comprised of the ECM, fuel pump assembly (low pressure side), and fuel pump control ECU assembly (which operates the fuel pump [low pressure side]). The ECM judges the speed of the fuel pump assembly (low pressure side) based on the engine output. This speed is converted into a loading signal, which is sent to the fuel pump control ECU assembly. The fuel pump control ECU assembly adjusts the fuel pump operating speed (low pressure side), based on the signal sent from the ECM.

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

1. PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP/SPEED)

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump/Speed.

(e) Check whether the fuel pump operating sound occurs when performing the Active Test on the Techstream.

Result

B -- INSPECT FUEL PUMP CONTROL ECU ASSEMBLY (POWER SOURCE VOLTAGE)

A -- Continue to next step.

2. PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP)

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Active Test /Control the Fuel Pump Duty.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

(f) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump/Speed.

(g) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

HINT

* Be sure to measure the voltage with all the connectors connected.

* Before performing this inspection, check that the battery voltage is between 11 and 14 V (not depleted).

NG -- REPLACE FUEL PUMP CONTROL ECU ASSEMBLY

OK -- Continue to next step.

3. CHECK HARNESS AND CONNECTOR (ECM - FUEL PUMP CONTROL ECU ASSEMBLY)

(a) Disconnect the ECM connector.

(b) Disconnect the fuel pump control ECU assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open):

Standard Resistance (Check for short):

NG -- REPAIR OR REPLACE HARNESS OR CONNECTOR

OK -- Continue to next step.

4. REPLACE FUEL PUMP ASSEMBLY

(a) Replace the fuel pump assembly Removal.

NEXT -- Continue to next step.

5. CHECK CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

(a) Check the fuel pump operation Fuel System.

OK:

Malfunction has been repaired successfully.

NG -- REPLACE ECM Removal

OK -- END

6. REPLACE FUEL PUMP CONTROL ECU ASSEMBLY

(a) Replace the fuel pump control ECU assembly Removal.

NEXT -- Continue to next step.

7. CHECK CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

(a) Check the fuel pump operation Fuel System.

OK:

Malfunction has been repaired successfully.

NG -- REPLACE ECM Removal

OK -- END

8. INSPECT FUEL PUMP CONTROL ECU ASSEMBLY (POWER SOURCE VOLTAGE)

(a) Disconnect the fuel pump control ECU assembly connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

NG -- CHECK HARNESS AND CONNECTOR (C/OPEN RELAY - FUEL PUMP CONTROL ECU ASSEMBLY)

OK -- Continue to next step.

9. CHECK HARNESS AND CONNECTOR (FUEL PUMP - FUEL PUMP CONTROL ECU ASSEMBLY)

(a) Disconnect the fuel pump connector.

(b) Disconnect the fuel pump control ECU assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open):

Standard Resistance (Check for short):

NG -- REPAIR OR REPLACE HARNESS OR CONNECTOR

OK -- Continue to next step.

10. INSPECT FUEL PUMP ASSEMBLY

(a) Inspect fuel pump assembly Inspection.

NG -- REPLACE FUEL PUMP ASSEMBLY Removal

OK -- Continue to next step.

11. CHECK HARNESS AND CONNECTOR (FUEL PUMP CONTROL ECU ASSEMBLY - ECM)

(a) Disconnect the ECM connector.

(b) Disconnect the fuel pump control ECU assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open):

Standard Resistance (Check for short):

NG -- REPAIR OR REPLACE HARNESS OR CONNECTOR

OK -- Continue to next step.

12. REPLACE FUEL PUMP CONTROL ECU ASSEMBLY

(a) Replace the fuel pump control ECU assembly Removal.

NEXT -- Continue to next step.

13. CHECK CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

(a) Check the fuel pump operation Fuel System.

OK:

Malfunction has been repaired successfully.

NG -- REPLACE ECM Removal

OK -- END

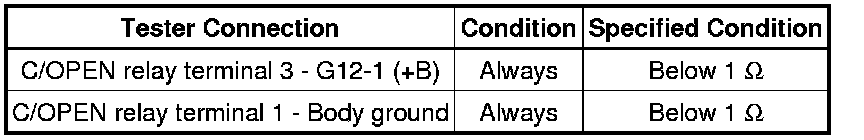

14. CHECK HARNESS AND CONNECTOR (C/OPEN RELAY - FUEL PUMP CONTROL ECU ASSEMBLY)

(a) Remove the C/OPEN relay from the engine room relay block assembly.

(b) Disconnect the fuel pump control ECU assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open):

Standard Resistance (Check for short):

NG -- REPAIR OR REPLACE HARNESS OR CONNECTOR

OK -- Continue to next step.

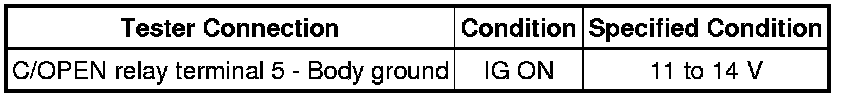

15. INSPECT TERMINAL VOLTAGE (C/OPEN RELAY)

(a) Remove the C/OPEN relay from the engine room relay block assembly.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

NG -- GO TO ECU POWER SOURCE CIRCUIT ECM Power Source Circuit

OK -- Continue to next step.

16. CHECK HARNESS AND CONNECTOR (C/OPEN RELAY - ECM - IG2 RELAY)

(a) Disconnect the ECM connector.

(b) Remove the C/OPEN relay and IG2 relay from the engine room relay block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open):

Standard Resistance (Check for short):

NG -- REPAIR OR REPLACE HARNESS OR CONNECTOR

OK -- REPLACE ECM Removal