Starter (For Manual Transmission)

FA20 STARTING: STARTER (for Manual Transmission): INSPECTION; 2013 MY FR-S [03/2012 -]

1. INSPECT STARTER ASSEMBLY

CAUTION:

As a large electric current passes through the cable during this inspection, a thick cable must be used. If not, the cable may become hot and cause injury.

NOTICE:

The following tests must each be performed within 3 to 5 seconds to prevent the coil from burning out.

(a) Mount the starter in a vise between aluminum plates.

(b) Perform a pull-in test.

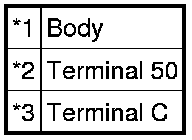

(1) Remove the nut, and then disconnect the lead wire from terminal C.

(2) Connect the battery to the starter as shown in the illustration. Check that the clutch pinion gear extends.

If the clutch pinion gear does not move, inspect the magnet starter switch assembly. If the magnet starter switch assembly is not as specified, replace it.

(c) Perform a holding test.

(1) Disconnect the negative (-) terminal lead from terminal C while the conditions specified in the pull-in test above are maintained. Check that the pinion gear remains out.

If the clutch pinion gear returns inward, inspect the magnet starter switch assembly. If the magnet starter switch assembly is not as specified, replace it.

(d) Inspect the clutch pinion gear return.

(1) Disconnect the negative (-) terminal lead from the starter body. Check that the clutch pinion gear returns inward.

If the clutch pinion gear does not return inward, inspect the magnet starter switch assembly. If the magnet starter switch assembly is not as specified, replace it.

(e) Perform an operation test without load.

(1) Connect the lead wire to terminal C with the nut.

Torque : 10 Nm (102 kgf-cm, 7 ft-lbf)

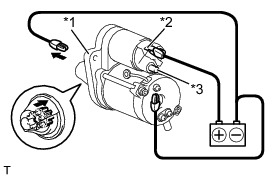

(2) Connect the battery and an ammeter to the starter as shown in the illustration.

(3) Check that the starter rotates smoothly and steadily while the clutch pinion gear is extended. Then measure the current.

Standard Current:

If the result is not as specified, inspect the starter assembly.

HINT

Inspect the starter armature assembly, starter commutator end frame assembly and magnet starter switch assembly. If there is a malfunction, replace the part and perform again this test.

2. INSPECT STARTER ARMATURE ASSEMBLY

(a) Check the commutator for signs of seizure or stepped wear caused by roughness of the surface. If there is light wear, use sandpaper to repair.

(b) Check for runout on the commutator. If excessive, replace the armature.

Standard runout:

0.05 mm (0.002 in.)

Maximum runout:

0.10 mm (0.004 in.)

(c) Check the depth of the segment mold. If it is not within the standard, replace the armature.

Standard depth:

0.50 mm (0.020 in.)

(d) Place the armature on the growler tester to check for short circuits. While slowly turning the armature, support the steel sheet for the armature core. If the circuit of the armature is shorted, the steel sheet will vibrate, causing it to move towards the core. When the steel sheet has moved or vibrated, replace the armature.

(e) Touch the probe of one side to the commutator segment, and the other probe to the shaft. If there is continuity, replace the armature.

3. INSPECT STARTER YOKE ASSEMBLY

(a) Make sure that the pole is set at the predetermined position.

4. INSPECT STARTER BRUSH HOLDER ASSEMBLY

(a) Visually check the brush. If there is any abnormal wear or cracks, replace the brush.

(b) Measure the length of the brush. If it exceeds the service limits, replace the brush.

Standard length:

12.3 mm (0.484 in.)

Minimum length:

7.0 mm (0.276 in.)

(c) Check that the brush moves smoothly in the brush holder.

(d) Measure the brush spring force with a spring scale. Replace the brush holder if below the service limit.

Standard brush spring force:

15.9 to 19.5 N (1.6 to 2.0 kgf, 3.6 to 4.4 lbf)

Minimum brush spring force:

2.5 N (0.3 kgf, 0.6 lbf)

5. INSPECT STARTER CLUTCH SUB-ASSEMBLY

(a) Check the gear teeth on the planetary gear, internal gear and starter clutch for wear or damage.

If any of the gears is damaged, replace the starter center bearing clutch sub-assembly.

(b) Check the starter clutch pinion gear.

(1) Hold the starter clutch, rotate the pinion gear clockwise and check that it turns freely. Try to rotate the pinion gear counterclockwise and check that it locks.

If necessary, replace the starter clutch sub-assembly.

6. INSPECT MAGNET STARTER SWITCH ASSEMBLY

(a) Check that there is continuity between terminals 50 and C, and between terminal 50 and ground. Also, check to be sure there is no continuity between terminal C and 30.

Standard Resistance:

(b) Using a lead wire, connect the switch assembly terminal 50 to the positive terminal of the battery, and the starter body to the ground terminal of the battery. The pinion should be forced to be pushed out on the shaft.

HINT

With the pinion forced to be pushed out on the shaft, the starter motor can sometimes rotate because the current flows, through pull-in coil, to motor. This is not a problem.

(c) Disconnect the connector from terminal C. Then, using a lead wire, connect the positive terminal of the battery and terminal C, and ground terminal to starter body. In this test set up, the pinion should return to its original position even when it is pulled out with a screwdriver.