Front Differential

Part 1 Of 2:

Part 2 Of 2:

DISASSEMBLY

1. CHECK COMPANION FLANGE RUNOUT

Using a dial indicator, measure the vertical and lateral runout of the companion flange.

Maximum runout: 0.10 mm (0.0039 inch)

If the runout exceeds the maximum, replace the companion flange.

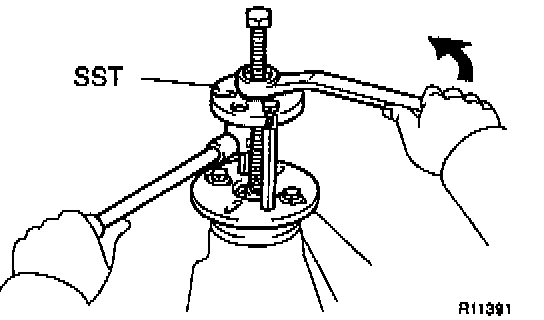

2. CHECK RING GEAR BACKLASH

Using SST and a dial indicator, measure the ring gear backlash.

SST 09564-32011

Backlash: 0.13-0.18 mm (0.0051-0.0071 inch)

HINT: Measure at 3 or more points on the circumference of the ring gear. If the backlash is not within the specified value, adjust the side bearing preload or repair as necessary.

3. MEASURE DRIVE PINION PRELOAD

Using a torque wrench, measure the preload using the backlash between the drive pinion and ring gear.

Preload (at starting): 0.6-1.0 Nm (6-10 kgf-cm, 5.2-8.7 inch lbs.)

4. CHECK TOTAL PRELOAD

Using a torque wrench, measure the total preload with the teeth of the drive pinion and ring gear in contact.

Total preload (at starting):

Drive pinion preload plus 0.4-0.6 Nm (4-6 kgf-cm, 3.5-5.2 inch lbs.)

If necessary, disassemble and inspect the differential.

5. REMOVE A.D.D. ACTUATOR

a. Remove the 4 bolts.

b. Using a hammer handle, remove the actuator.

6. REMOVE DIFFERENTIAL TUBE

a. Using a torx socket (E14), remove the 4 torx bolts.

b. Using a plastic hammer, tap on the differential tube to remove it.

c. Remove the sleeve.

d. Remove the O-ring from the differential tube.

7. REMOVE CLUTCH CASE

a. Using a torx socket (E14), remove the 2 torx bolts.

b. Using a plastic hammer, tap on the clutch case to remove it.

8. REMOVE SIDE OIL SEAL

Using SST, remove the side oil seal.

SST 09308-00010

9. REMOVE INTERMEDIATE SHAFT NO. 1

a. Using SST, remove the intermediate shaft No. 1.

SST 09350-20015 (09369-20040), 09950-40011 (09951-04010, 09952-04010, 09953-04020, 09954-04010, 09955-04011, 09957-04010, 09958-04011)

b. Remove the snap ring.

10. REMOVE COMPANION FLANGE

a. Using a chisel and hammer, unstake the nut.

b. Using SST to hold the flange, remove the nut.

SST 09330-00021

c. Using SST, remove the companion flange.

SST 09950-30011 (09951-03010, 09953-03010, 09954-03010, 09955-03030, 09956-03020)

11. REMOVE OIL SEAL AND OIL SLINGER

a. Using SST, remove the oil seal.

SST 09308-10010

b. Remove the oil slinger.

12. REMOVE REAR BEARING AND BEARING SPACER

a. Using SST, remove the rear bearing from the drive pinion.

SST 09556-22010

b. Remove the bearing spacer.

13. REMOVE SIDE BEARING RETAINER

Remove the 10 bolts and tap out the retainer with a plastic hammer.

14. REMOVE DIFFERENTIAL CASE ASSEMBLY

15. REMOVE DRIVE PINION FROM DIFFERENTIAL CARRIER

16. REMOVE DRIVE PINION FRONT BEARING

Using SST and a press, remove the bearing and washer from the drive pinion.

SST 09950-00020

HINT: If the drive pinion or ring gear is damaged, replace them as a set.

17. REMOVE DRIVE PINION BEARING OUTER RACES

a. Using a brass bar and hammer, remove the front bearing outer race.

b. Using SST, remove the rear bearing outer race.

SST 09502-12010, 09612-65014 (09612-01020, 09612-01050)

18. REMOVE SIDE BEARING OUTER RACES

HINT:

- Measure the plate washer thickness and note it down.

- Tag the bearing outer races to show the location for reassembling.

a. Using SST and a press, remove the plate washer and outer race from the bearing retainer.

SST 09950-60010 (09951-00540), 09950-70010 (09951-07150)

b. Using SST and a press, remove the plate washer and outer race from the differential carrier.

SST 09950-60010 (09951-00650), 09950-70010 (09951-07150)

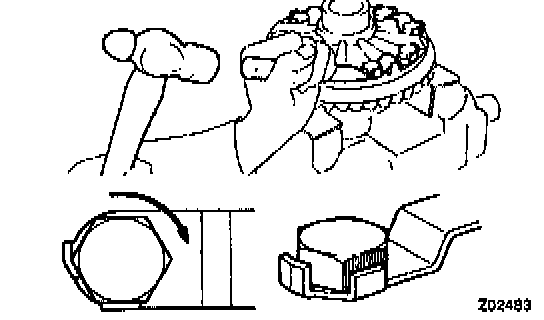

19. REMOVE RING GEAR

a. Place matchmarks on the ring gear and differential case.

b. Using a screwdriver and hammer, unstake the 5 lock plates.

c. Remove the 10 bolts and 5 lock plates.

d. Using a plastic hammer, tap on the ring gear to separate it from the differential case.

20. REMOVE SIDE BEARINGS

Using SST, remove the 2 side bearings from the differential case.

SST 09950-40011 (09951-04010, 09952-04010, 09953-04020, 09954-04010, 09955-04061, 09957-04010, 09958-04011), 09950-60010 (09951-00480)

HINT: Fix the claws of SST to the notch in the differential case.

21. DISASSEMBLE DIFFERENTIAL CASE ASSEMBLY

a. Using a pin punch and hammer, remove the straight pin.

b. Remove the pinion shaft, 2 pinion gears, pinion gear thrust washers, side gears and side gear thrust washers from the differential case.

22. REMOVE BEARINGS

Using a brass bar and hammer, remove the 2 bearings.

REPLACEMENT

1. REPLACE COMPANION FLANGE DUST DEFLECTOR, IF NECESSARY

a. Using SST, a socket wrench and a press, remove the dust deflector.

SST 09950-00020

b. Using SST and a press, install a new dust deflector.

SST 09636-20010

2. REPLACE INTERMEDIATE SHAFT NO. 2, IF NECESSARY

a. Remove the clutch hub.

1. Using a snap ring expander, remove the snap ring.

2. Remove the clutch hub from the intermediate shaft No. 2.

b. Remove the oil seal.

Using SST, remove the oil seal from the tube.

SST 09308-00010

c. Remove the intermediate shaft No. 2 from the tube.

1. Using needle nose pliers, remove the snap ring.

2. Remove the shaft from the tube.

d. Remove the intermediate shaft No. 2 bearing.

1. Using a snap ring expander, remove the snap ring.

2. Using SST, a brass bar and press, remove the bearing.

SST 09950-00020

e. Install a new intermediate shaft No. 2 bearing.

1. Using SST and a press, install a new bearing.

SST 09309-37010

2. Using a snap ring expander, install a new snap ring.

f. Install the intermediate shaft No. 2 to the tube.

1. Install the shaft into the tube.

2. Using needle nose pliers, install a new snap ring.

g. Install a new oil seal.

1. Using SST and a plastic hammer, install a new oil seal.

SST 09223-15020

Oil seal drive in depth: 5.5 ± 0.3 mm (0.217 ± 0.012 inch)

2. Coat the oil seal lip with MP grease.

h. Install the clutch hub.

1. Install the clutch hub to the shaft.

2. Using a snap ring expander, install a new snap ring.

REASSEMBLY

1. INSTALL NEW BEARINGS

Using SST and a press, install 2 new bearings.

SST 09950-60010 (09951-00380)

Bearing press in depth: 0.3 ± 0.3 mm (0.012 ± 0.012 inch)

2. ASSEMBLE DIFFERENTIAL CASE

a. Install the 2 thrust washers on the side gears.

b. Install the 2 side gears, pinion gears, pinion gear thrust washers and pinion shaft in the differential case.

HINT: Align the holes for the straight pin in the differential case and pinion shaft.

c. Using a dial indicator, measure the side gear backlash while holding one pinion gear toward the differential case.

Backlash: 0-0.20 mm (0-0.0079 inch)

If the backlash is not within the specified value, replace the side gear thrust washer with the one of an appropriate thickness.

HINT: Refer to the following table to select thrust washers which will ensure that the backlash is within the specified value.

Washer Thickness:

3. INSTALL STRAIGHT PIN AND STAKE DIFFERENTIAL CASE

a. Using a pin punch and hammer, install the straight pin through the differential case and hole in the pinion shaft.

b. Stake the differential case.

4. INSTALL RING GEAR ON DIFFERENTIAL CASE

a. Clean the contact surfaces of the differential case and ring gear.

b. Heat the ring gear to about 100°C (212°F) in boiling water.

c. Carefully take the ring gear out of the boiling water.

d. After the moisture on the ring gear has completely evaporated, quickly install the ring gear to the differential case.

HINT: Align the matchmarks on the ring gear and differential case.

e. Temporarily install 5 new lock plates and 10 bolts so that the bolt holes in the ring gear and differential case are aligned.

f. After the ring gear has cooled sufficiently, torque the ring gear set bolts.

Torque: 97 Nm (985 kgf-cm, 71 ft. lbs.)

g. Using a chisel and hammer, stake the 5 lock plates.

HINT: Stake the claws of the lock plates to fix the bolts. For the claw contacting the protruding portion of the bolt, stake only the half of it along the tightening direction.

5. INSTALL SIDE BEARINGS

Using SST and a press, install the bearings into the differential case.

SST 09226-10010

6. INSTALL SIDE BEARING OUTER RACES

If replacing the side bearings, fit the thinnest new plate washers to each bearing outer race.

If reusing the bearings, fit the new washers with the same thickness as removed.

a. Install a new plate washer to the side bearing retainer.

b. Using SST and a press, install the bearing outer race.

SST 09950-60020 (09951-00790), 09950-70010 (09951-07150)

c. Install a new plate washer to the differential carrier.

d. Using SST and a press, install the bearing outer race.

SST 09950-60020 (09951-00790), 09950-70010 (09951-07150)

7. INSTALL DRIVE PINION FRONT AND REAR BEARING OUTER RACES

Using SST, install the 2 outer races.

SST 09570-22011

8. INSTALL DRIVE PINION FRONT BEARING

a. Install the washer on the drive pinion.

HINT: First fit a washer with the same thickness as the washer which was removed, then after checking the tooth contact pattern, replace the washer with one of a different thickness if necessary.

b. Using SST and a press, install the front bearing onto the drive pinion.

SST 09506-30012

9. TEMPORARILY ADJUST DRIVE PINION PRELOAD

a. Install the drive pinion, rear bearing and oil slinger.

HINT: After adjusting the ring gear tooth contact pattern, assemble the spacer and oil seal.

b. Using SST, install the companion flange.

SST 09950-30011 (09951-03010, 09953-03010, 09954-03010, 09955-03030, 09956-03020)

c. Coat the threads of the nut with hypoid gear oil.

d. Using SST to hold the flange, tighten the nut.

HINT: Adjust the drive pinion preload by tightening the companion flange nut.

SST 09330-00021

NOTICE: As there is no spacer, tighten the nut a little at a time and be careful not to overtighten it.

e. Using a torque wrench, measure the preload of the drive pinion using the backlash between the drive pinion and ring gear.

Preload (at starting):

New bearing 1.2-1.9 Nm (12-19 kgf-cm, 10.4-16.5 inch lbs.)

Reused bearing 0.6-1.0 Nm (6-10 kgf-cm, 5.2-8.7 inch lbs.)

10. INSTALL DIFFERENTIAL CASE IN DIFFERENTIAL CARRIER

11. ADJUST RING GEAR BACKLASH

a. Install the side bearing retainer with the 10 bolts.

Torque: 69 Nm (700 kgf-cm, 51 ft. lbs.)

b. Using SST and a dial indicator, measure the ring gear backlash.

SST 09564-32011

Backlash: 0.13-0.18 mm (0.0051-0.0071 inch)

If the backlash is not within the specified value, adjust it by either increasing or decreasing the thickness of plate washers on both sides by an equal amount.

HINT: There should be no clearance between the plate washer and case. Ensure that there is ring gear backlash.

Washer Thickness:

12. MEASURE TOTAL PRELOAD

Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

Total preload (at starting):

Drive pinion preload plus 0.4-0.6 Nm (4-6 kgf-cm, 3.5-5.2 inch lbs.)

13. INSPECT TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION

a. Remove the 10 bolts, side bearing retainer and differential case.

b. Coat 3 or 4 teeth at three different positions on the ring gear with red lead primer.

c. Install the differential case and side bearing retainer with the 10 bolts.

Torque: 69 Nm (700 kgf-cm, 51 ft. lbs.)

d. Hold the companion flange firmly and rotate the ring gear in both directions.

e. Remove the 10 bolts, side bearing retainer and differential case.

f. Inspect the tooth contact pattern.

If the teeth are not contacting properly, use the following table to select a proper washer for correction.

Washer Thickness:

14. REMOVE COMPANION FLANGE AND OIL SLINGER

15. REMOVE REAR BEARING

16. INSTALL NEW BEARING SPACER, REAR BEARING AND OIL SLINGER

a. Install a new bearing spacer and place the rear bearing and oil slinger.

b. Using SST and the companion flange, install the rear bearing, then remove the companion flange.

SST 09950-30011 (09951-03010, 09953-03010, 09954-03010, 09955-03030, 09956-03020)

17. INSTALL OIL SEAL

a. Using SST and a hammer, install a new oil seal.

SST 09554-22010

Oil seal drive in depth: 4.5 ± 0.3 mm (0.177 ± 0.012 inch)

b. Coat the oil seal lip with MP grease.

18. INSTALL COMPANION FLANGE

a. Place the companion flange on the drive pinion.

b. Coat the threads of a new nut with hypoid gear oil.

c. Using SST to hold the flange, torque the nut.

SST 09330-00021

Torque: 108 Nm (1,100 kgf-cm, 80 ft. lbs.)

19. ADJUST DRIVE PINION PRELOAD

Using a torque wrench, measure the preload of the drive pinion using the backlash between the drive pinion and the ring gear.

Preload (at starting):

New bearing 1.2-1.9 Nm (12-19 kgf-cm, 10.4-16.5 inch lbs.)

Reused bearing 0.6-1.0 Nm (6-10 kgf-cm, 5.2-8.7 inch lbs.)

If the preload is greater than the specified value, replace the bearing spacer.

If the preload is less than the specified value, retighten the nut with 13 Nm (130 kgf-cm, 9 ft. lbs.) of torque at a time until the specified preload is reached.

Torque: 223 Nm (2,275 kgf-cm, 165 ft. lbs.) or less

If the maximum torque is exceeded while retightening the nut, replace the bearing spacer and repeat the preload adjusting procedure. Do not loosen the nut to reduce the preload.

20. INSTALL DIFFERENTIAL CASE

21. INSTALL SIDE BEARING RETAINER

a. Remove any old FIPG material and be careful not to drop oil on the contact surfaces of the differential carrier and side bearing retainer.

b. Clean both installation surfaces of loose FIPG and oil material with gasoline or alcohol.

c. Apply FIPG to the side bearing retainer, as shown in the illustration.

FIPG: Part No. 08826-00090, THREE BOND 1281 or equivalent

HINT: Install the side bearing retainer within 10 minutes after applying FIPG.

d. Install the side bearing retainer with the 10 bolts.

Torque: 69 Nm (700 kgf-cm, 51 ft. lbs.)

22. CHECK TOTAL PRELOAD (See step 12.)

23. RECHECK RING GEAR BACKLASH

24. RECHECK TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION (See step 13.)

25. CHECK COMPANION FLANGE RUNOUT

26. STAKE DRIVE PINION NUT

27. INSTALL SIDE OIL SEAL

a. Using SST and a plastic hammer, install a new oil seal until its surface is flush with the differential carrier end.

SST 09608-32010

b. Coat the oil seal lip with MP grease.

28. INSTALL INTERMEDIATE SHAFT NO. 1

a. Install a new snap ring to the shaft.

b. Using a plastic hammer, install the shaft to the differential case.

c. Check that there is 2-3 mm (0.08-0.12 inch) of play in the axial direction.

d. Check that the intermediate shaft will not come out by trying to pull it completely out by hand.

29. INSTALL CLUTCH CASE TO DIFFERENTIAL TUBE

a. Install a new O-ring to the tube.

b. Coat the O-ring with MP grease.

c. Install the clutch case to the tube.

d. Using a torx socket (E 14), torque the 2 torx bolts.

Torque: 78 Nm (800 kgf-cm, 58 ft. lbs.)

30. INSTALL CLUTCH SLEEVE

31. INSTALL DIFFERENTIAL TUBE TO DIFFERENTIAL

a. Remove any old FIPG material and be careful not to drop oil on the contact surfaces of the differential and clutch case.

b. Clean both installation surfaces of loose FIPG and oil material with gasoline or alcohol.

c. Apply FIPG to the differential, as shown in the illustration.

FIPG: Part No. 08826-00090, THREE BOND 1281 or equivalent

HINT: Install the differential tube within 10 minutes after applying FIPG.

d. Install the differential tube to the differential.

e. Clean the threads of the 2 long torx bolts and retainer bolt holes with toluene or trichloroethylene.

f. Apply adhesive to 2 or 3 threads of the long bolts end.

Adhesive: Part No. 08833-00070, THREE BOND 1324 or equivalent

g. Using torx socket E14 (Part No. 09044-00010 or locally manufactured tool), torque the 4 torx bolts.

Torque: 78 Nm (800 kgf-cm, 58 ft. lbs.)

32. INSTALL A.D.D. ACTUATOR

a. Remove any old FIPG material and be careful not to drop oil on the contact surfaces of the actuator and clutch case.

b. Clean both installation surfaces of loose FIPG and oil material with gasoline or alcohol.

c. Apply FIPG to the clutch case, as shown in the illustration.

FIPG: Part No. 08826-00090, THREE BOND 1281 or equivalent

HINT: Install the actuator within 10 minutes after applying FIPG.

d. Install the A.D.D. actuator with the 4 bolts.

Torque: 21 Nm (210 kgf-cm, 15 ft. lbs.)