Fuel Pressure: Testing and Inspection

FUEL PRESSURE INSPECTION

CHECK FUEL PRESSURE

(a) Check the battery positive voltage is above 12 V.

(b) Disconnect the negative (-) terminal cable from the battery.

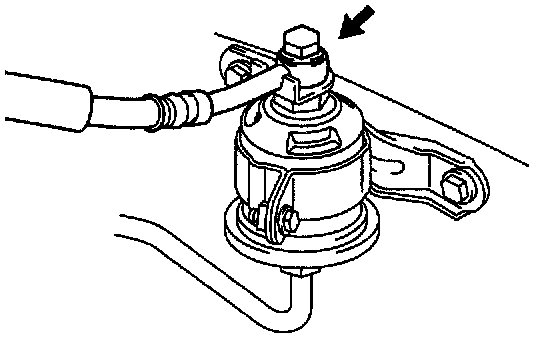

(c) Remove the union bolt and 2 gaskets, and disconnect the fuel inlet hose from the fuel filter outlet.

CAUTION:

- Put a shop towel under the fuel filter.

- Slowly loosen the union bolt.

(d) Install the fuel inlet hose and SST (pressure gauge) to the fuel filter outlet with the 3 gaskets and SST (union bolt). SST 0926-5012 (09268-41190, 90405-06167)

Torque: 29 N.m (300 kgf.cm, 22 ft.lbf)

(e) Wipe off any splattered gasoline.

(f) Reconnect the negative (-) terminal cable to the battery.

(g) Connect the TOYOTA hand-held tester to the DLC3.

(h) Turn the ignition switch ON.

(i) Measure the fuel pressure.

Fuel pressure: 265-304 kPa (2.7-3.1 kgf/sq. cm, 38-44 psi)

If pressure is high, replace the fuel pressure regulator. If pressure is low, check these parts:

- Fuel hoses and connections

- Fuel pump

- Fuel filter

- Fuel pressure regulator

(j) Disconnect the TOYOTA hand-held tester from the DLC3.

(k) Reinstall the fuse cover on the instrument panel.

(l) Start the engine.

(m) Measure the fuel pressure at idle.

Fuel pressure: 226-265 kPa (2.3-2.7 kgf/sq.cm, 33-38 psi)

(n) Stop the engine.

(o) Check that the fuel pressure remains as specified for 5 minutes after the engine has stopped.

Fuel pressure: 147 kPa (1.5 kgf/sq.cm, 21 psi) or more

If pressure is not as specified, check the fuel pump, pressure regulator and/or injectors.

(p) After checking fuel pressure, disconnect the negative (-) terminal cable from the battery and carefully remove the SST to prevent gasoline from splashing. SST 09263-45012

(q) Reconnect the fuel inlet hose with 2 new gaskets and the union bolt.

Torque:29 N.m (300 kgf.cm, 21 ft.lbf)

(r) Reconnect the negative (-) terminal cable to the battery.

(s) Check for fuel leakage.

3. REMOVE REAR SEAT CUSHION

4. REMOVE SERVICE HOLE COVER

5. DISCONNECT FUEL PUMP AND SENDER GAUGE CONNECTOR

6. INSPECT FUEL PUMP RESISTANCE

Using an ohmmeter, measure the resistance between terminals 4 and 5.

Resistance: 0.2-3.0 Ohm at 20°C (68°F)

If the resistance is not as specified, replace the fuel pump, lead wire or fuel pump bracket.

7. INSPECT FUEL PUMP OPERATION

Connect a tester lead from terminal 4 of the connector to the positive (+) terminal of the battery; connect another tester lead from terminal 5 of the connector to the negative (-) terminal of the battery.

NOTICE:

- These tests must be done quickly (within 10 seconds) to prevent the coil from burning out.

- Keep the fuel pump as far away from the battery as possible.

- Always connect or disconnect at the battery. If operation is not as specified, replace the fuel pump, lead wire or fuel pump bracket.

8. RECONNECT FUEL PUMP AND SENDER GAUGE CONNECTOR

9. REINSTALL SERVICE HOLE COVER

10. REINSTALL REAR SEAT CUSHION