Drum Brake System: Service and Repair

REMOVAL

1. INSPECT SHOE LINING THICKNESS

Remove the inspection hole plug, and check the shoe lining thickness through the hole.

If less than minimum, replace the shoes.

Minimum thickness: 1.0 mm (0.039 inch)

2. REMOVE REAR WHEEL

3. REMOVE BRAKE DRUM

a. Release the parking brake lever, and remove the brake drum.

HINT: If the brake drum cannot be removed easily, do the following steps.

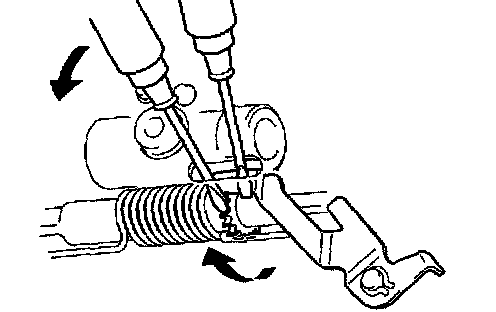

b. Remove the plug and insert a screwdriver through the hole in the backing plate.

c. Using another screwdriver, reduce the brake shoe adjuster by turning the adjusting wheel.

4. REMOVE FRONT SHOE

a. Using SST, disconnect the adjuster spring from the rear shoe.

SST 09703-30010

b. Using needle-nose pliers, remove the anchor spring.

c. Using SST, remove the cap, shoe hold-down spring and pin from the front shoe.

SST 09718-00010

d. Remove the adjuster and adjuster spring together with the front shoe.

e. Remove the adjuster together with the adjuster spring from the front shoe.

f. Using needle-nose pliers, remove the adjusting lever spring.

g. Remove the automatic adjusting lever from the front shoe.

5. REMOVE REAR SHOE

a. Using SST, remove the cap, shoe hole-down spring and pin.

SST 09718-00010

b. Using needle-nose pliers, disconnect the parking brake cable from the parking brake lever, and remove the rear shoe.

6. REMOVE PARKING BRAKE LEVER

a. Remove the C-washer.

b. Remove the parking lever from the rear shoe.

7. REMOVE WHEEL CYLINDER

a. Using SST, disconnect the brake line. Use container to catch the brake fluid.

SST 09751-36011

Torque:15 Nm (155 kgf-cm, 11 ft. lbs.)

b. Remove the 2 bolts and the wheel cylinder.

Torque:10 Nm (100 kgf-cm, 7 ft. lbs.)

8. DISASSEMBLE WHEEL CYLINDER

a. Remove the 2 boots from the wheel cylinder.

b. Remove the 2 pistons from the wheel cylinder.

c. Remove the spring from the wheel cylinder.

d. Remove the 2 piston cups from each piston.

INSPECTION

1. INSPECT DISASSEMBLED PARTS

Inspect the disassembled parts for wear, rust or damage.

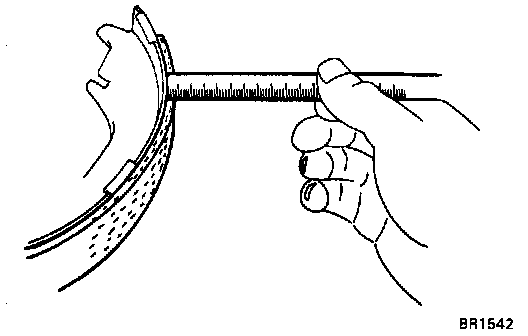

2. MEASURE BRAKE SHOE LINING THICKNESS

Using a ruler, measure the shoe lining thickness.

Standard thickness: 4.0 mm (0.157 inch)

Minimum thickness: 1.0 mm (0.039 inch)

If the thickness is less than the minimum or shoe lining shows signs of uneven wear, replace the brake shoes.

HINT: If a brake shoes needs replacing, the brake shoes must be replaced as a set

3. MEASURE BRAKE DRUM INSIDE DIAMETER

Using a brake drum gauge or equivalent, measure the inside diameter of the drum.

Standard inside diameter: 200.0 mm (7.874 inch)

Maximum inside diameter: 201.0 mm (7.913 inch)

If the drum is scored or worn, the brake drum may be lathed to the maximum inside diameter.

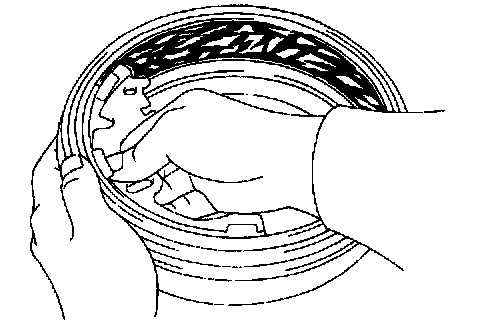

4. INSPECT REAR BRAKE LINING AND DRUM FOR PROPER CONTACT

If the contact between the brake lining and drum is improper, repair the lining with a brake shoe grinder, or replace the brake shoe assembly.

INSTALLATION

Installation is in the reverse order of removal.

NOTICE: Apply lithium soap base glycol grease and high temperature grease to the parts indicated by the arrows.

1. CHECK OPERATION OF AUTOMATIC ADJUSTING MECHANISM

a. Move the parking brake lever of the rear shoe back and forth. Check that the adjuster turns.

If the adjuster does not turn, check for incorrect installation of the rear brake.

b. Adjust the adjuster length to the as short as possible.

c. Install the brake drum.

d. Pull the parking brake lever all the way up until a clicking sound can no longer be heard.

2. CHECK CLEARANCE BETWEEN BRAKE SHOES AND DRUM

a. Remove the brake drum.

b. Measure the brake drum inside diameter and diameter of the brake shoes. Check that the difference between the diameters is the correct shoe clearance.

Shoe clearance: 0.6 mm (0.024 inch)

If incorrect, check the parking brake system.

c. Install the brake drum.

3. FILL BRAKE RESERVOIR WITH BRAKE FLUID

4. BLEED BRAKE SYSTEM

5. CHECK FOR LEAKS

6. INSTALL REAR WHEEL

Torque: 103 Nm (1,050 kgf-cm, 76 ft. lbs.)