Disassembly

Part 1 Of 3:

Part 2 Of 3:

Part 3 Of 3:

DISASSEMBLY

1. REMOVE FILLER PLUG AND DRAIN PLUG WITH 2 GASKETS

Torque: 39 Nm (400 kgf-cm, 29 ft. lbs.)

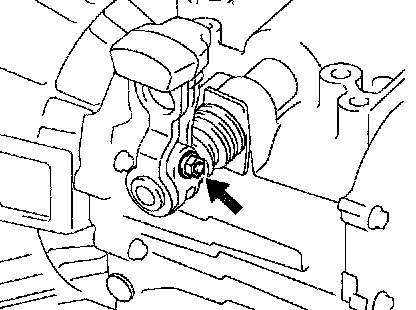

2. REMOVE VEHICLE SPEED SENSOR

a. Remove the bolt and vehicle speed sensor.

Torque: 11 Nm (115 kgf-cm, 8 ft. lbs.)

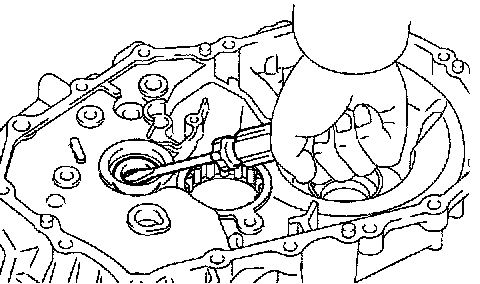

b. Using a small screwdriver, remove the clip from the vehicle speed sensor.

c. Remove the vehicle speed sensor driven gear from the speed sensor

d. Using a small screwdriver, remove the O-ring from the vehicle speed sensor.

3. REMOVE BACK-UP LIGHT SWITCH WITH GASKET

Torque: 40 Nm (410 kgf-cm, 30 ft. lbs.)

4. REMOVE CONTROL CABLE BRACKET

Remove the 2 bolts and control cable bracket.

Torque: 25 Nm (250 kgf-cm, 18 ft. lbs.)

5. REMOVE CONTROL SHAFT ASSEMBLY

Remove the 2 nuts, wave washer and control shaft assembly.

Torque: 12 Nm (120 kgf-cm, 9 ft. lbs.)

6. REMOVE SELECTING BELLCRANK ASSEMBLY

a. Remove the 2 bolts and selecting bellcrank assembly

Torque: 25 Nm (250 kgf-cm, 18 ft. lbs.)

NOTICE:

At the time of reassembly, please refer to the following item.

Fit the selecting bellcrank assembly pin part with the dust cover into a groove in the control shift lever.

b. Remove the control bellcrank dust cover from the selecting bellcrank assembly.

NOTICE:

At the time of reassembly, please refer to the following item.

Apply MP grease to the inside circumferential surface of the control bellcrank dust cover.

7. REMOVE CONTROL SHIFT LEVER AND DUST BOOT

a. Remove the nut and wave washer.

Torque: 12 Nm (120 kgf-cm, 9 ft. lbs.)

b. Using a pin punch and hammer, drive out the lever lock pin.

NOTICE:

At the time of reassembly, please refer to the following item.

When fixing the lever lock pin, properly position the shaft groove.

c. Remove the control shift lever and dust boot.

NOTICE: At the time of reassembly, please refer to the following items.

^ Install the dust boot into a groove in the control shift lever.

^ Be sure to install the dust boot in the correct direction, as shown in the illustration.

8. REMOVE TRANSMISSION CASE COVER

a. Remove the 9 bolts.

Torque: 18 Nm (185 kgf-cm, 13 ft. lbs.)

b. Using a brass bar and hammer, carefully tap the projection of the transmission case cover to remove the transmission case cover from the transmission case.

HINT:

At the time of reassembly, please refer to the following item.

Apply FIPG to the transmission case cover, as shown in the illustration.

FIPG: Part No. 08826-00090, THREE BOND 1281 or equivalent

9. REMOVE LOCK BALL ASSEMBLY AND CONTROL SHAFT COVER

a. Remove the lock assembly.

Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Torque: 29 Nm (300 kgf-cm, 22 ft. lbs.)

b. Remove the 4 bolts and control shaft cover with the gasket.

Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Torque: 20 Nm (200 kgf-cm, 14 ft. lbs.)

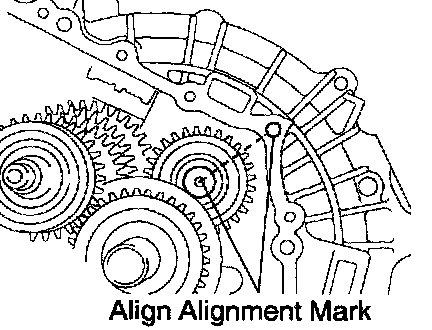

10. REMOVE SHIFT AND SELECT LEVER SHAFT ASSEMBLY

NOTICE:

At the time of reassembly, please refer to the following item.

Set the claws of the shift interlock plate into the shift head part of the gear shift fork shaft securely.

11. REMOVE LOCK NUT

a. Engage the gear double meshing.

b. Using a chisel and hammer, loosen the staked part of the nut.

c. Remove the lock nut.

Torque: 118 Nm (1,200 kgf-cm, 87 ft. lbs.)

d. Disengage the gear double meshing.

12. REMOVE NO.3 HUB SLEEVE AND NO.3 GEAR SHIFT FORK

a. Remove the bolt from the No.3 gear shift fork.

Torque: 16 Nm (160 kgf-cm,12 ft. lbs.)

Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

b. Remove the No. 3 hub sleeve with the No. 3 gear shift fork.

HINT: At the time of reassembly, please refer to the following items.

^ Install the No. 3 clutch hub assembly to the No. 3 hub sleeve.

^ Before driving in the No.3 clutch hub assembly, place the suitable sized wooden block on the rear side of the input shaft, as shown in the illustration. When driving it in, fix the input shaft firmly so that it is not pushed downward. Otherwise the input shaft rear radial ball bearing is overloaded, it might be damaged.

^ Using SST and a hammer, drive in the No. 3 hub sleeve assembly with the No. 3 gear shift fork.

SST 09636-20010

NOTICE:

^ Be sure to install the No.3 hub Reeve assembly in the correct direction, as shown in the illustration.

^ Align the No. 3 synchronizer ring slots with the No. 3 shifting keys.

13. INSPECT 5TH GEAR THRUST CLEARANCE

Using a dial indicator, measure the thrust clearance.

Standard clearance: 0.10 - 0.57 mm (0.0039 - 0.0224 inch)

Maximum clearance: 0.57 mm (0.0224 inch)

14. INSPECT 5TH GEAR RADIAL CLEARANCE

Using a dial indicator, measure the radial clearance.

Standard clearance:

KOYO made: 0.015 - 0.058 mm (0.0006 - 0.0023 inch)

NSK made: 0.015 - 0.056 mm (0.0006 - 0.0022 inch)

Maximum clearance:

KOYO made: 0.058 mm (0.0023 inch)

NSK made: 0.056 mm (0.0022 inch)

If the clearance exceeds the maximum, replace the gear, needle roller bearing or shaft.

15. REMOVE NO. 3 CLUTCH HUB AND 5TH GEAR

a. Using 2 screwdrivers and a hammer, tap out the snap ring.

HINT:

At the time of reassembly, please refer to the following item.

Select a snap ring from the table that will make the thrust clearance of the No.3 clutch hub less than 0.1 mm (0.0039 inch).

b. Using a screwdriver, remove the shifting key spring from the No. 3 clutch hub.

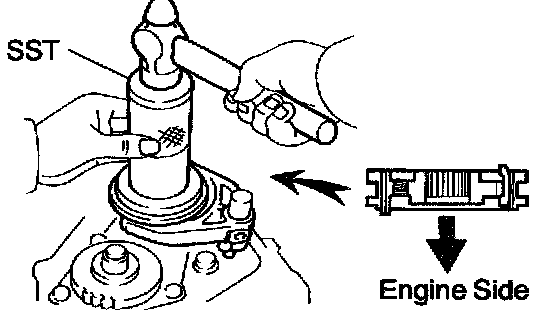

c. Install a bolt and washer to the tip of the input shaft and using SST, remove the No. 3 clutch hub.

SST 09950-30012

HINT: Select a bolt whose outer diameter is smaller than the screw hole of the input shaft so that it can be turned easily.

d. Remove the No.3 synchronizer ring, 5th gear, needle roller bearing and spacer.

16. REMOVE 5TH DRIVEN GEAR

Using SST, remove the 5th driven gear.

SST 09628-62011, 09950-40011 (09957-04010), 09950-60010 (09951-00230)

HINT:

At the time of reassembly, please refer to the following item.

Using SST, install the 5th driven gear.

SST 09309-12020

17. REMOVE REAR BEARING RETAINER

Remove the 5 bolts and rear bearing retainer.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Torque: 27 Nm (280 kgf-cm, 20 ft. lbs.)

18. REMOVE BEARING SNAP RING

Using a snap ring expander, remove the 2 snap rings.

HINT: If it is difficult to remove and install the snap rings, pull up the shafts.

19. REMOVE REVERSE IDLER GEAR SHAFT LOCK BOLT AND GASKET

Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Torque: 29 Nm (300 kgf-cm, 22 ft. lbs.)

20. REMOVE SNAP RING FROM NO. 2 SHIFT FORK SHAFT

Using 2 screwdrivers and a hammer, tap out the snap ring.

21. REMOVE STRAIGHT SCREW PLUG, SEAT, SPRING AND BALL

a. Using a hexagon wrench, remove the 3 straight screw plugs.

Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Torque: 25 Nm (250 kgf-cm, 18 ft. lbs.)

b. Using a magnetic finger, remove the 3 seats, springs and balls.

22. REMOVE LOCK BALL ASSEMBLY

Using a hexagon wrench, remove the lock ball assembly.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Torque: 39 Nm (400 kgf-cm, 29 ft. lbs.)

23. REMOVE TRANSMISSION CASE

a. Remove the 16 bolts.

Torque: 29 Nm (300 kgf-cm, 22 ft. lbs.)

b. Using a plastic hammer, carefully tap the projection of the transmission case to remove the transmission case from the transaxle case.

HINT:

At the time of reassembly, please refer to the following item.

Apply FIPG to the transaxle case, as shown in the illustration.

FIPG: Part No.08826-00090, THREE BOND 1281 or equivalent

24. REMOVE OIL RECEIVER PIPE

Remove the 2 bolts and oil receiver pipes from the transmission case.

Torque: 17 Nm (175 kgf-cm, 13 ft. lbs.)

NOTICE: At the time of reassembly, please refer to the following items.

^ Prevent the oil receiver pipes from being deformed.

^ Install the oil receiver pipes while placing it against the transmission case, as shown in the illustration.

25. REMOVE REVERSE IDLER GEAR, THRUST WASHER AND SHAFT

26. REMOVE REVERSE SHIFT ARM BRACKET

Remove the 2 bolts and reverse shift arm bracket.

Torque: 17 Nm (175 kgf-cm, 13 ft. lbs.)

NOTICE: At the time of reassembly, please refer to the following items.

^ Set the pin on the top of the reverse shift arm into a groove on the reverse idler gear.

^ Fit the claw of the reverse shift arm bracket with the notch of the input shaft front bearing.

^ Install the reverse idler gear, thrust washer and shaft, as shown in the illustration.

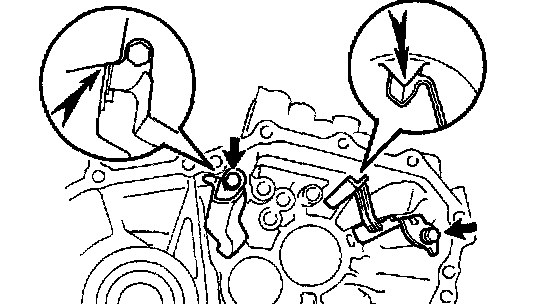

27. REMOVE GEAR SHIFT FORK AND GEAR SHIFT FORK SHAFT

a. Using 2 screwdrivers and a hammer, tap out the 3 snap rings from each gear shift fork shaft.

b. Remove the 3 bolts from the No. 1 gear shift head, No. 1 and No. 2 gear shift forks.

Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

Torque: 16 Nm (160 kgf-cm, 12 ft. lbs.)

c. Pull up the No. 3 gear shift fork shaft, remove the No. 2 gear shift fork shaft.

NOTICE:

At the time of reassembly, please refer to the following item.

To avoid the interference of the 2 balls, lift up the No. 3 gear shift fork shaft at the position shown in the illustration.

d. Remove the No. 1 gear shift head.

e. Using a magnetic finger, remove the 2 balls from the reverse shift fork.

f. Remove the No. 3 gear shift fork shaft and reverse shift fork.

g. Pull out the No. 1 gear shift fork shaft.

h. Remove the No. 1 and No. 2 gear shift forks.

28. REMOVE INPUT AND OUTPUT SHAFTS TOGETHER FROM TRANSAXLE CASE

29. REMOVE DIFFERENTIAL CASE ASSEMBLY

NOTICE:

At the time of reassembly, please refer to the following item.

Before reassembly, inspect the differential tapered roller bearing preload.

30. REMOVE MAGNET FROM TRANSAXLE CASE

31. DISASSEMBLE NO. 3 CLUTCH HUB ASSEMBLY

a. Using a screwdriver, remove the shifting key spring.

NOTICE:

At the time of reassembly, please refer to the following item.

Position the shifting key springs so that their end gaps are not aligned.

b. Remove the 3 No. 3 shifting keys from the No. 3 clutch hub.

INSPECTION

1. INSPECT 5TH GEAR SYNCHRONIZER RING

a. Check for wear or damage.

b. Check the braking effect of the synchronizer ring. Turn the synchronizer ring in one direction while pushing it to the gear cone. Check that the ring locks.

If the braking effect is insufficient, apply a small amount of the fine lapping compound between the synchronizer ring and gear cone. Lightly rub the synchronizer ring and gear cone together.

NOTICE: Ensure the fine lapping compound is completely washed off after.

c. Check again the braking effect of the synchronizer ring.

d. Using a feeler gauge, measure the clearance between the synchronizer ring back and gear spline end.

Minimum clearance: 0.5 mm (0.020 inch)

If the clearance is less than the minimum, replace the synchronizer ring, and apply a small amount of the fine lapping compound on gear cone.

NOTICE: Ensure the fine lapping compound is completely washed off after rubbing.

2. INSPECT GEAR SHIFT FORK AND HUB SLEEVE CLEARANCE

Using a feeler gauge, measure the clearance between the hub sleeve and gear shift fork.

Maximum clearance: 0.5 mm (0.020 inch)

If the clearance exceeds the maximum, replace the gear shift fork or hub sleeve.

3. REMOVE TRANSAXLE CASE RECEIVER

Remove the bolt and transaxle case receiver from the transaxle case.

4. IF NECESSARY, REPLACE INPUT SHAFT FRONT BEARING AND OIL SEAL

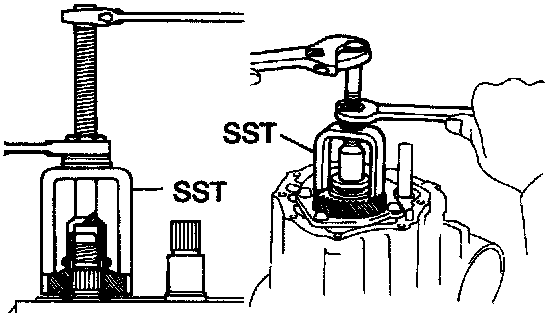

a. Using SST, remove the input shaft front bearing.

SST 09612-65014

b. Using a screwdriver, remove the oil seal.

c. Using SST and a hammer, drive in a new oil seal.

SST 09950-60010 (09951-00360), 09950-70010 (09951-07150)

Drive in depth: 15.8 ± 0.2 mm (0.622 ± 0.008 inch)

d. Coat the lip of the oil seal with MP grease.

e. Using SST and a press, install a new input shaft front bearing.

SST 09950-60010 (09951-00400), 09950-70010 (09951-07150)

Drive in depth: 0 - 0.3 mm (0 - 0.012 inch)

NOTICE: Be sure to install a new bearing in the correct direction, as shown in the illustration.

5. IF NECESSARY, REPLACE OUTPUT SHAFT FRONT BEARING AND OUTPUT SHAFT COVER

a. Remove the bolt and bearing lock plate.

b. Using SST, pull out the output shaft front bearing.

SST 09308-00010

c. Remove the output shaft cover.

d. Install the output shaft cover.

NOTICE: Install the output shaft cover projection into the case side hollow.

e. Using SST and a press, install a new output shaft front bearing.

SST 09950-60010 (09951-00560), 09950-70010 (09951-07150)

NOTICE:

^ Be sure to install a new bearing in the correct direction, as shown in the illustration.

^ When replacing the output shaft front bearing, replace the output shaft front bearing inner race along with it.

f. Install the bearing lock plate with the bolt.

Torque: 11 Nm (115 kgf-cm, 8 ft. lbs.)

6. INSTALL TRANSAXLE CASE RECEIVER

Install the transaxle case receiver to the transaxle case with the bolt.

Torque: 11 Nm (115 kgf-cm, 8 ft. lbs.)

7. IF NECESSARY, REPLACE REVERSE RESTRICT PIN

a. Using a hexagon wrench, remove the straight screw plug.

b. Using a pin punch and hammer, drive out the slotted spring pin.

c. Replace the reverse restrict pin.

d. Using a pin punch and hammer, drive in the slotted spring pin.

e. Apply sealant to the screw plug threads.

Sealant: Part No. 08833-00080, THREE BOND 1344, LOCTITE 242 or equivalent

f. Using a hexagon wrench, install the straight screw plug.

Torque: 13 Nm (130 kgf-cm, 9 ft. lbs.)

8. IF NECESSARY, REPLACE TRANSMISSION CASE BUSHING

a. Using a socket wrench (12 mm), extension bar and plastic hammer, drive out the bushing.

NOTICE: When driving out the bushing, be careful not to damage the transmission case by the socket wrench.

b. Using SST and a hammer, drive in a new bushing.

SST 09950-60010 (09951-00180), 09950-70010 (09951-07100)

Drive in depth: 0.80 - 1.30 mm (0.0315 - 0.0512 inch)

9. IF NECESSARY, REPLACE TRANSMISSION CASE OIL SEAL

a. Using a screwdriver and hammer, drive out the oil seal.

b. Using a socket wrench (17 mm) and plastic hammer, drive in a new oil seal.

Drive in depth: 10.0 ± 0.3 mm (0.394 ± 0.012 inch)

c. Coat the lip of the oil seal with MP grease.