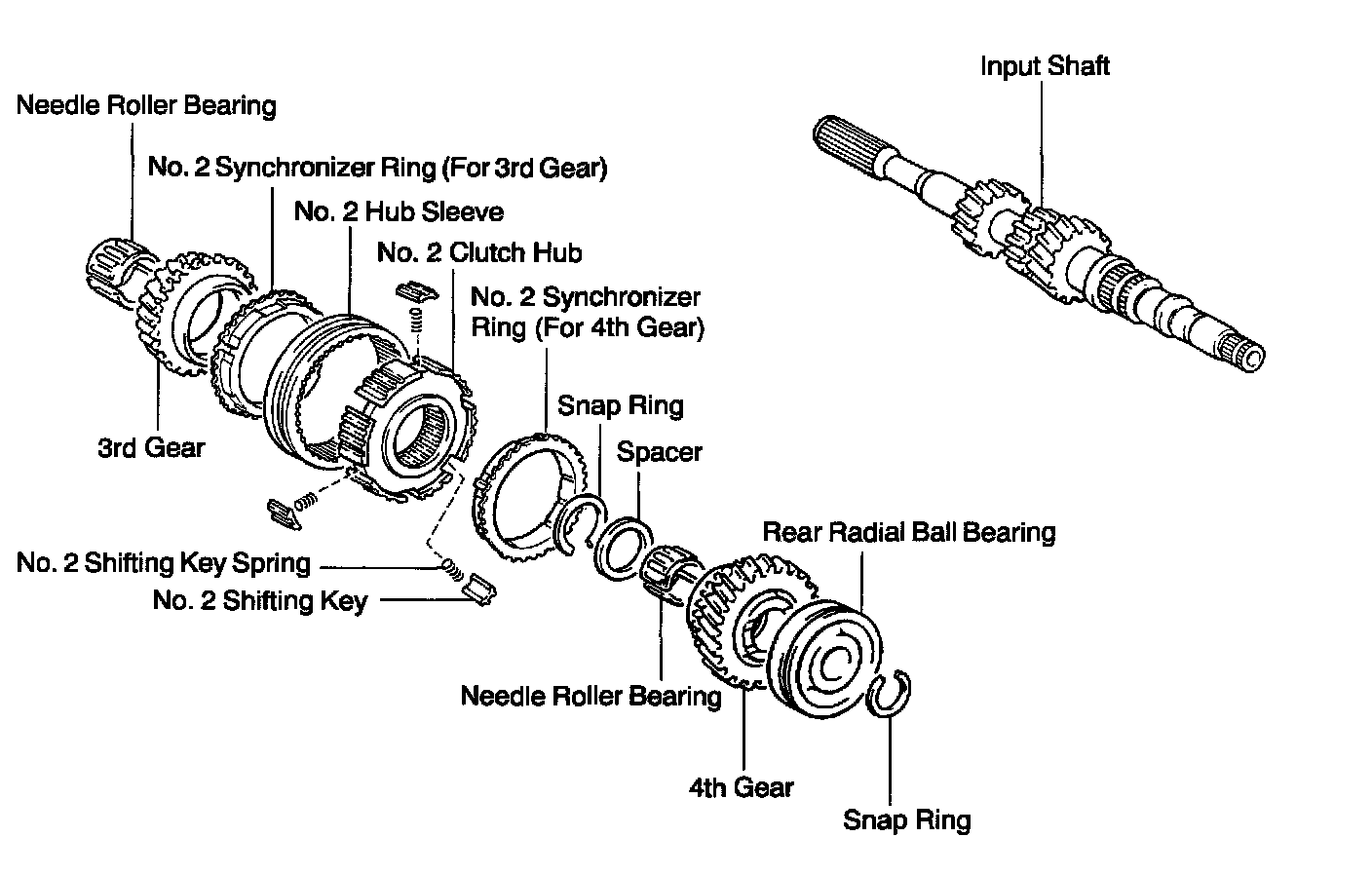

Input Shaft

DISASSEMBLY

1. INSPECT 3RD AND 4TH GEARS THRUST CLEARANCE

Using a feeler gauge, measure the thrust clearance.

Standard clearance:

3rd gear: 0.10 - 0.35 mm (0.0039 - 0.0138 inch)

4th gear: 0.10 - 0.55 mm (0.0039 - 0.0217 inch)

Maximum clearance:

3rd gear: 0.35 mm (0.0138 inch)

4th gear: 0.55 mm (0.0217 inch)

2. INSPECT 3RD AND 4TH GEARS RADIAL CLEARANCE

Using a dial indicator, measure the radial clearance between the gear and shaft.

Standard clearance:

KOYO made: 0.015 - 0.058 mm (0.0006 - 0.0023 inch)

NSK made: 0.015 - 0.056 mm (0.0006 - 0.0022 inch)

Maximum clearance:

KOYO made: 0.058 mm (0.0023 inch)

NSK made: 0.056 mm (0.0022 inch)

If the clearance exceeds the maximum, replace the gear, needle roller bearing or shaft.

3. REMOVE SNAP RING

Using 2 screwdrivers and a hammer, tap out the snap ring.

HINT: Take care not to damage the journal surface of the input shaft.

4. REMOVE REAR RADIAL BALL BEARING, 4TH GEAR, NEEDLE ROLLER BEARING, SPACER AND NO. 2 SYNCHRONIZER RING (FOR 4TH GEAR) FROM INPUT SHAFT

a. Using SST and a press, remove the rear radial ball bearing and 4th gear.

SST 09950-00020

HINT: Support the input shaft assembly by hand so that it will not be dropped off.

b. Remove the needle roller bearings, spacer and No. 2 synchronizer ring (for the 4th gear).

5. REMOVE SNAP RING

Using 2 screwdrivers and a hammer, tap out the snap ring.

HINT: Take care not to damage the journal surface of the input shaft.

6. REMOVE NO. 2 HUB SLEEVE ASSEMBLY, 3RD GEAR, NO. 2 SYNCHRONIZER RING (FOR 3RD GEAR) AND NEEDLE ROLLER BEARING

a. Using SST and a press, remove the No. 2 hub sleeve assembly, 3rd gear and No. 2 synchronizer ring (for the 3rd gear).

SST 09950-00020

HINT: Support the input shaft by hand so that it will not be dropped off.

b. Remove the needle roller bearings.

7. DISASSEMBLE NO. 2 HUB SLEEVE ASSEMBLY

a. Remove the No. 2 hub sleeve from the No. 2 clutch hub.

b. Remove the 3 No. 2 shifting keys and No. 2 shifting key springs from the No. 2 clutch hub.

INSPECTION

1. INSPECT SYNCHRONIZER RING

a. Check for wear or damage.

b. Check the braking effect of the synchronizer ring. Turn the synchronizer ring in one direction while pushing it to the gear cone. Check that the ring locks.

If the braking effect is insufficient, apply a small amount of the fine lapping compound between the synchronizer ring and gear cone. Lightly rub the synchronizer ring and gear cone together.

NOTICE: Ensure the fine lapping compound is completely washed off after rubbing.

c. Check again the braking effect of the synchronizer ring.

d. Using a feeler gauge, measure the clearance between the synchronizer ring back and gear spline end.

Minimum clearance:

3rd gear: 0.65 mm (0.0256 inch)

4th gear: 0.75 mm (0.0295 inch)

If the clearance is less than the minimum, replace the synchronizer ring, and apply a small amount of the fine lapping compound on gear cone.

NOTICE: Ensure the fine lapping compound is completely washed off after rubbing.

2. INSPECT GEAR SHIFT FORK AND HUB SLEEVE CLEARANCE

Using a feeler gauge, measure the clearance between the hub sleeve and gear shift fork.

Maximum clearance: 0.35 mm (0.014 inch)

If the clearance exceeds the maximum, replace the gear shift fork or hub sleeve.

3. INSPECT INPUT SHAFT

a. Check the input shaft for wear or damage.

b. Using a micrometer, measure the outer diameter of the input shaft journal surface.

Minimum outer diameter:

Part A: 24.885 mm (0.9797 inch)

Part B: 28.985 mm (1.1411 inch)

Part C: 30.985 mm (1.2199 inch)

Part D: 24.985 mm (0.9837 inch)

If the outer diameter is less than the minimum, replace the input shaft.

c. Using a dial indicator, check the shaft runout.

Maximum runout: 0.03 mm (0.0012 inch)

If the runout exceeds the maximum, replace the input shaft.

REASSEMBLY

HINT: Coat all of the sliding and rotating surfaces with gear oil before reassembly.

1. ASSEMBLE NO. 2 HUB SLEEVE ASSEMBLY

a. Install the 3 No. 2 shifting key springs and No. 2 shifting keys to the No. 2 clutch hub.

b. Install the No. 2 hub sleeve to the No. 2 clutch hub.

NOTICE: Assemble the No. 2 hub sleeve and No. 2 clutch hub in the direction shown in the illustration.

2. INSTALL NEEDLE ROLLER BEARING, 3RD GEAR, NO. 2 SYNCHRONIZER RING (FOR 3RD GEAR) AND NO. 2 HUB SLEEVE ASSEMBLY TO INPUT SHAFT

a. Apply gear oil to the needle roller bearings and install it.

b. Install the 3rd gear and No. 2 synchronizer ring (for the 3rd gear).

NOTICE: Distinguish the No. 2 synchronizer ring (for the 3rd gear) by the teeth on the synchronizer ring.

c. Install the No. 2 hub sleeve assembly so that the No. 2 synchronizer ring slots and No. 2 shifting keys are aligned.

NOTICE: Be sure to install the No. 2 hub sleeve assembly in the correct direction, as shown in the illustration.

d. Using a press, install the No. 2 hub sleeve assembly.

3. INSTALL SNAP RING

a. Select a snap ring from the table that will make the thrust clearance of the No. 2 clutch hub less than 0.1 mm (0.0039 inch).

b. Using a screwdriver and hammer, tap in the snap ring.

HINT: Take care not to damage the journal surface of the input shaft.

4. INSPECT 3RD GEAR THRUST CLEARANCE

5. INSTALL SPACER, NEEDLE ROLLER BEARING, NO. 2 SYNCHRONIZER RING (FOR 4TH GEAR), 4TH GEAR AND REAR RADIAL BALL BEARING

a. Install the spacer.

b. Apply gear oil to the needle roller bearings and install it.

c. Place the No. 2 synchronizer ring (for the 4th gear) on the No. 2 hub sleeve assembly and align the No. 2 synchronizer ring slots with the No. 2 shifting keys.

d. Install the 4th gear.

NOTICE: Distinguish the No. 2 synchronizer ring (for the 4th gear) by the teeth on the synchronizer ring.

e. Using SST and a press, install the rear radial ball bearing.

SST 09608-00071

NOTICE: Be sure to install the rear radial ball bearing in the correct direction, as shown in the illustration.

HINT: Set SST to the bearing inner race securely.

6. INSTALL SNAP RING

a. Select a snap ring from the table that will make the thrust clearance of the rear radial ball bearing less than 0.1 mm (0.0039 inch).

b. Using a screwdriver and hammer, tap in the snap ring.

HINT: Take care not to damage the journal surface of the input shaft.

7. INSPECT 4TH GEAR THRUST CLEARANCE