Locks: Service and Repair

Key and Lock Cylinder Coding

Tools Required

BO-47869 Lock Cylinder Staking Tool

The ignition lock cylinder used 7 of the 10 key cut positions, 4-10 when counting from the key head. The tumbler (3) orientations alternate in adjacent locations from side to side with 3 on one side and 4 on the other.

Caution: Wear safety glasses in order to avoid eye damage.

Important: The ignition lock cylinder tumblers (3) are not self-retaining and must be held in place if the key is not fully inserted into the lock cylinder.

1. Hold the uncoded cylinder plug (5) positioned so the side with the sidebar slot is facing to the left and the 3 spring holes are on top.

2. Insert one tumbler spring (7) each into the 3 tumbler spring holes.

3. The first tumbler to be loaded will be key cut position number 5, the fifth number in the key code. Determine the cut depth at this position and install the corresponding tumbler (8) into the tumbler slot second from the front of the cylinder plug (5) (the end where the key is inserted).

4. In the same manner, determine the cut depth and corresponding tumbler and install the 2 remaining tumblers (8) into the tumbler slots located at key cut positions 7 and 9.

5. Check for correct loading by holding the tumblers (8) in position and fully inserting the matching key into the cylinder plug (5). All tumblers should be flush with the outside diameter of the cylinder plug.

6. Rotate the cylinder plug (5) so that the side with the sidebar slot is facing to the right and then remove the matching key. Remember the tumblers (8) are not self-retaining and must be held in place.

7. Insert one tumbler spring (7) each into the 4 tumbler spring holes.

8. The first tumbler to be loaded will be key cut position number 4. Determine the cut depth at this position and install the corresponding tumbler (8) into the tumbler slot nearest the front of the cylinder plug (5).

9. In the same manner, determine the cut depth and corresponding tumbler and install the 3 remaining tumblers (8) into the slots located at key cut positions 6, 8, and 10.

10. Check for correct loading by holding the tumblers (8) in position and fully inserting the matching key into the cylinder plug assembly (5). All tumblers should be flush with the outside diameter of the cylinder plug.

11. Lightly lubricate tumbler (8) surfaces using the lubrication provided.

12. Hold the cylinder plug (5) positioned so the side with the sidebar slot is facing to the left. Insert the U-shaped plunger shaft (6) into the grooves on the right side of the cylinder plug.

13. Install the cylinder plug assembly (5) into the cylinder sleeve assembly (4). There is a slight interference fit between the cylinder plug and the cylinder sleeve assembly, so be sure that the cylinder plug is fully seated into the bottom of the cylinder sleeve. The cylinder plug should be slightly below flush with the inner face of the cylinder sleeve. Once the cylinder plug assembly is fully installed into the cylinder sleeve assembly, the tumblers (8) will be fully enclosed and retained.

14. Install the actuator (11) into the pocket in the front face of the cylinder plug.

15. Install the security plate (10) on top of the cylinder plug in the cylinder sleeve assembly.

Notice: Refer to Fastener Notice.

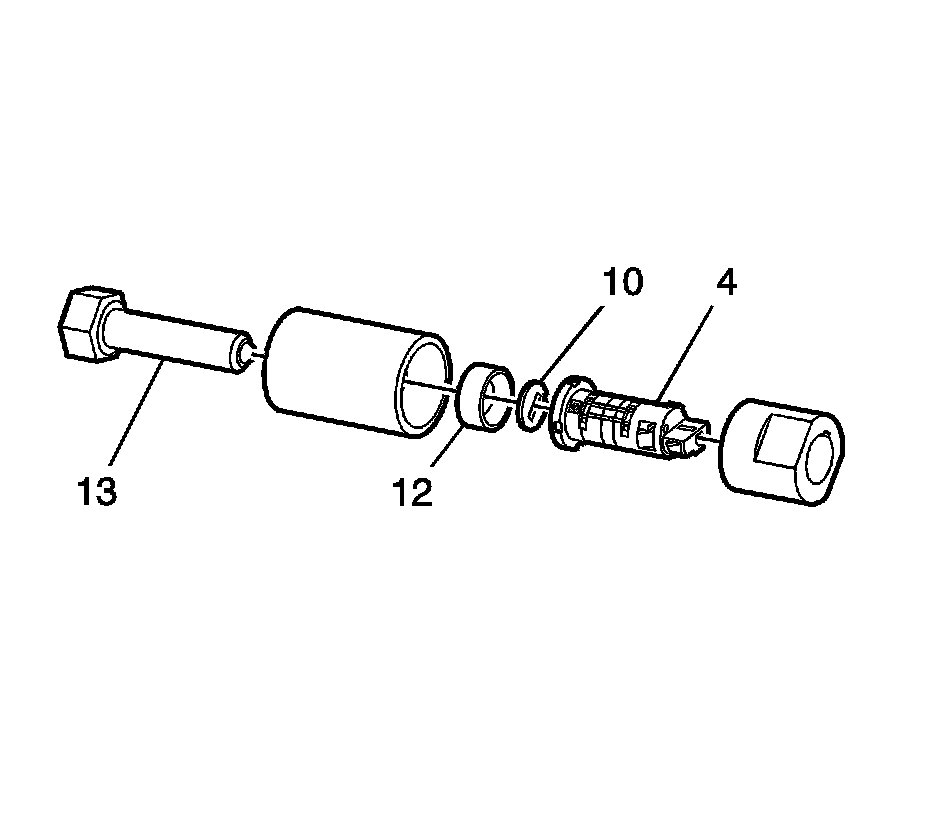

16. Securely stake the security plate (10) into the cylinder sleeve assembly (4) by using the appropriate staking tool BO-47869. Assemble the cylinder sleeve assembly, security plate, and staking tool BO-47869. When loading cylinder sleeve assembly into the staking tool, ensure staking cup number 12 is positioned cup toward cylinder sleeve. Secure assembled staking tool in a vise. Rotate the forcing screw (13) in order to uniformly stake the cylinder sleeve material over the security plate.

Tighten the forcing screw (13) to 23-28 N.m (17-21 lb ft). Once the security plate has been staked to the assembly, ensure the actuator (11) can rotate freely inside the assembly by inserting a key and removing it.

17. Install and stake the cover (9) onto the head of the cylinder sleeve assembly (4) by crimping the cover material in 4 places into the pockets around the head of the cylinder sleeve. Ensure the cover is securely held onto the cylinder sleeve and that the key can be inserted into the cylinder sleeve assembly through the slot in the cover.

18. Install the sidebar (3) into the cylinder sleeve assembly (4).

19. Install the 2 sidebar springs (2) into the cylinder sleeve assembly (4).

20. Install the stake and the 2 sidebar spring retainers (1) onto the cylinder sleeve assembly (4) by crimping the material on the cylinder sleeve onto the sidebar spring retainers. Ensure the sidebar spring retainers are securely attached to the cylinder sleeve.

21. Insert the matching key into the cylinder assembly and confirm the following:

1. The sidebar drops to be flush or below flush with the outer diameter of the cylinder sleeve (4) when the matching key is fully inserted into the cylinder assembly.

2. The sidebar protrudes out of the diameter of the cylinder sleeve when the matching key is removed from the cylinder assembly.

3. With the matching keys installed, the plunger protrudes to be flush or almost flush with the rear of the cylinder sleeve.

22. Install the ignition cylinder assembly into the steering column of the vehicle