Engine Replacement

Engine Replacement

Removal Procedure

1. With the tires in the straight forward position, remove the key from the ignition.

2. Disconnect the negative battery cable.

3. Remove the air outlet duct.

4. Secure the cooling module to the upper body structure.

5. Relieve the fuel system pressure. Refer to Fuel Pressure Relief.

6. Disconnect the fuel line from the fuel rail.

7. Drain the cooling system. Refer to Draining and Filling Cooling System (2.0L (LSJ)) Draining and Filling Cooling System (2.2L (L61), 2.4L (LE5)) Draining and Filling Cooling System (GE 47716 Fill).

8. Remove the radiator inlet hose.

9. Remove the surge tank to cylinder head pipe.

10. Remove the radiator outlet hose.

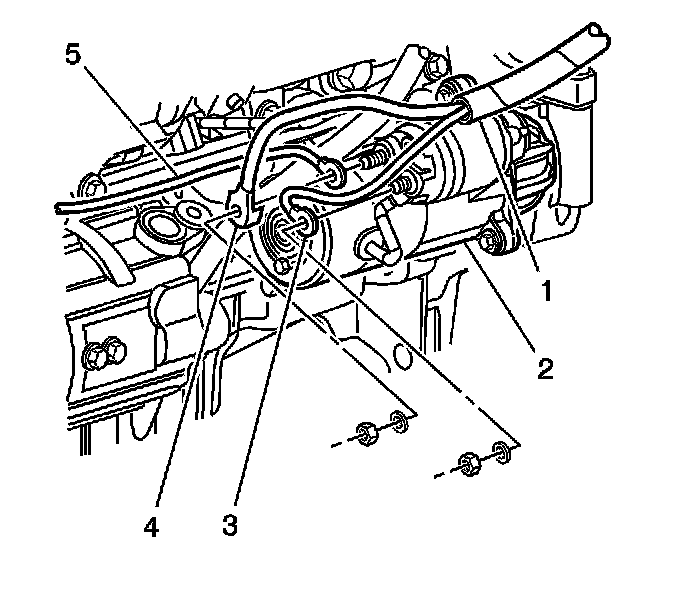

11. Remove the inlet (1) and outlet (2) heater hoses.

12. Disconnect the following harness connectors:

* TMAP sensor

* Electronic temperature control (ETC)

* Manifold absolute pressure (MAP) sensor

* Barometric pressure (BARO) sensor

* Crankshaft sensor

* Oil pressure sensor

* Purge solenoid

* Ignition coil modules

* Oxygen (O2) sensor

* Vehicle speed sensor

* Engine temperature sensor

* Boost solenoid

* Back-up lamp switch

13. Remove the engine drive belt.

14. Raise and suitably support the vehicle. Refer to Lifting and Jacking the Vehicle.

15. Recover the refrigerant. Refer to Refrigerant Recovery and Recharging.

16. Disconnect the compressor and condenser hose assembly from the compressor.

17. Remove the AC compressor bolts and set the compressor aside.

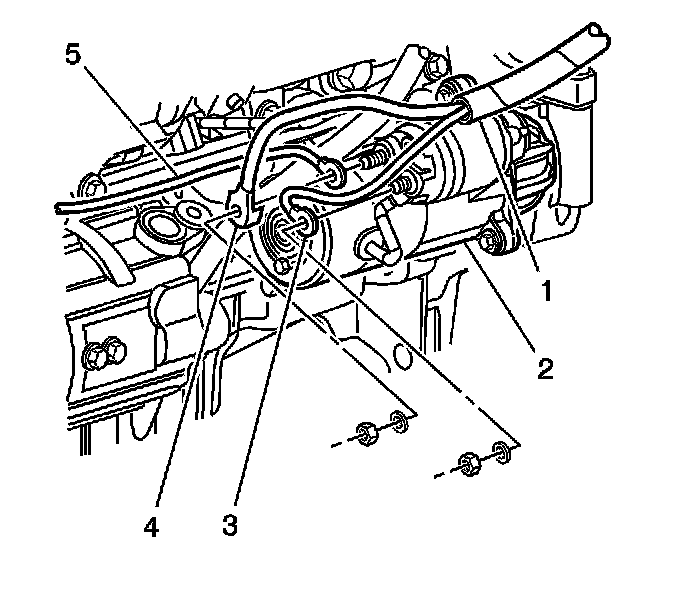

18. Disconnect the starter harness connectors (3, 4, 5).

19. Disconnect the generator harness connectors.

20. Drain the engine oil.

21. Disconnect the front exhaust pipe from the exhaust manifold.

22. Disconnect the transmission shift cable from the transmission.

23. Use blocks of wood to support the powertrain assembly between the frame and the powertrain.

24. Remove the engine mount.

25. Remove the left transmission mount.

26. Disconnect the stabilizer links from the stabilizer bar.

27. Disconnect the outer tie rod ends from the steering knuckles.

Important: In order to prevent possible SIR system deployment, do not attempt to rotate the steering shaft.

28. Disconnect the intermediate shaft from the steering gear.

29. Disconnect the lower control arms from the steering knuckles.

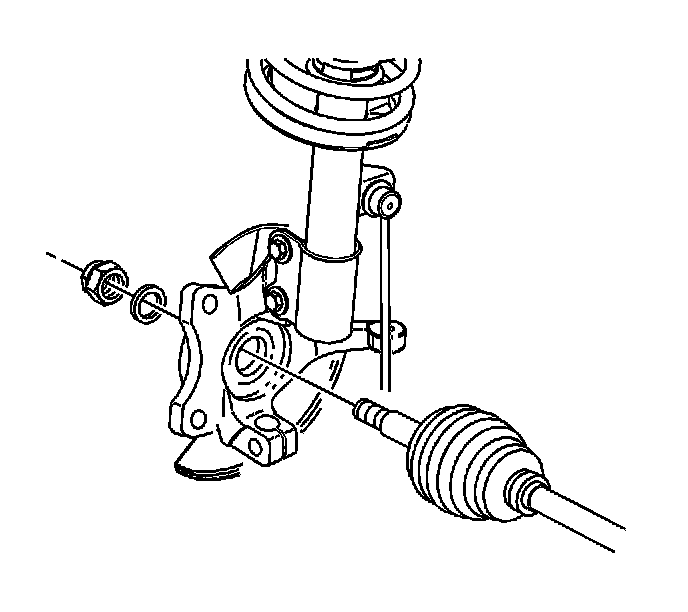

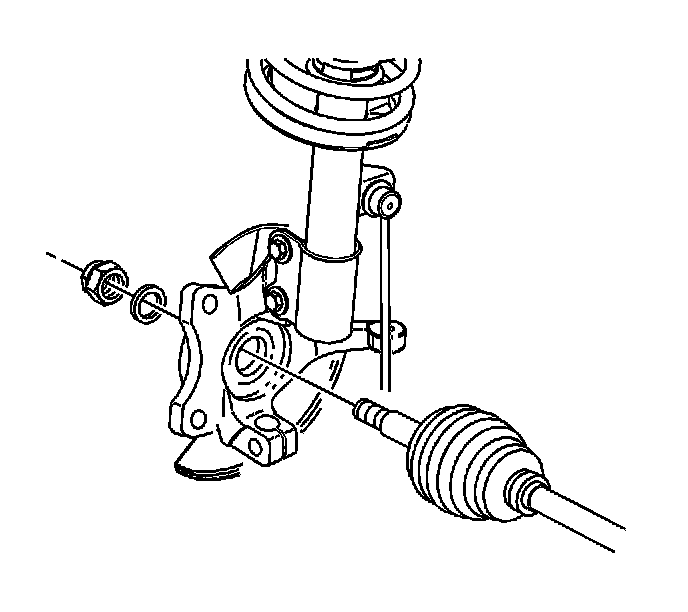

30. Disconnect the drive axles from the steering knuckle.

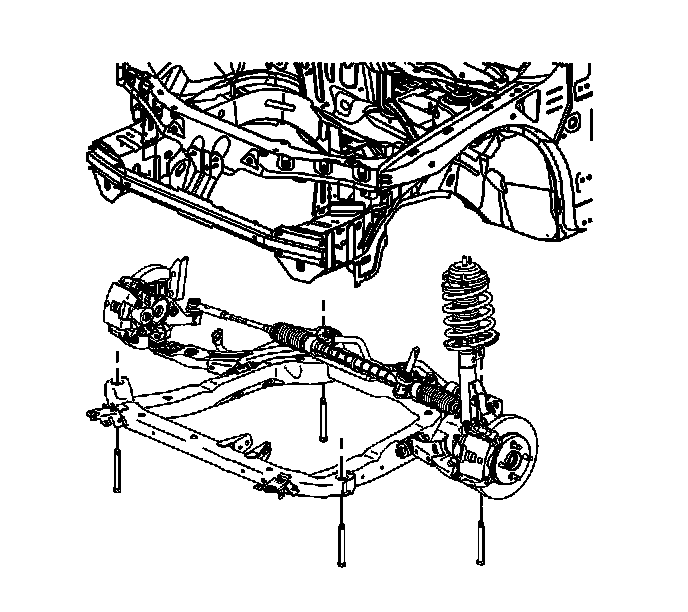

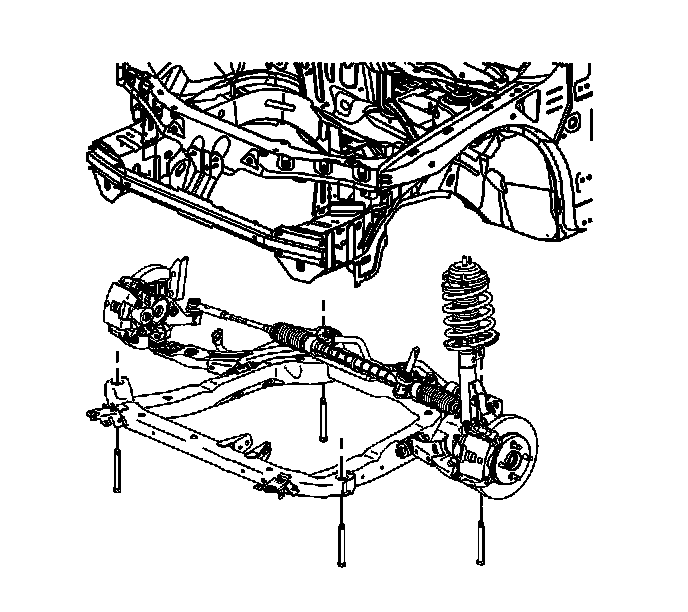

32. Lower the vehicle to about 1 meter (3 feet) off the ground in order to position the lift table under the frame.

33. Use wood blocks as necessary between the lift table and the frame to support the assembly.

34. Slowly remove the frame bolts using the following sequence:

1. Remove the front frame bolts.

2. Partially unscrew the rear frame bolts until 38 mm (1.5 in) of bolt shank is exposed.

35. Slowly lower the table to the floor.

36. Attach the engine lift hoist to the engine lift hooks.

37. Remove the starter.

38. Remove the transmission to engine bolts.

39. Separate the engine from the transmission.

40. Remove the clutch pressure plate and disk.

41. Remove the following components:

* The exhaust manifold

* The exhaust manifold studs

* The engine mount bracket

* The fuel rail

* The thermostat housing and feed pipe

* The generator

42. Remove the engine from the engine lift.

Installation Procedure

1. Attach the engine lift hoist to the engine lift hooks.

2. Install the following components:

* The exhaust manifold-Refer to Exhaust Manifold Replacement (RPO L61) Exhaust Manifold Replacement (RPO LE5) Exhaust Manifold Replacement (RPO LSJ).

* The fuel rail-Refer to Fuel Rail Assembly Replacement.

* The idler pulley

* The drive belt tensioner-Refer to Drive Belt Tensioner Replacement - Supercharger.

* The thermostat housing and feed pipe-Refer to Thermostat Replacement (RPO L61) Thermostat Replacement (RPO LE5) Thermostat Replacement (RPO LSJ).

* The generator-Refer to Generator Replacement (RPO LSJ) Generator Replacement (RPOs L61/LE5).

* The flywheel-Refer to Engine Flywheel Replacement.

* The clutch pressure plate and disk-Refer to Clutch Drive Plate and Clutch Driven Plate (M86) Clutch Drive Plate and Clutch Driven Plate (MU3).

* The AC compressor-Refer to Compressor Replacement (RPO LSJ) Compressor Replacement (RPOs L61, LE5).

3. Align the engine to the transmission.

Notice: Refer to Fastener Notice.

Important: The number 3 bolt location is not used.

4. Secure the engine to the transmission.

Tighten the transmission to engine bolts to 75 N.m (55 lb ft).

5. Install the starter.

6. Remove the engine lift from the engine.

7. Raise and position the frame and powertrain assembly to the vehicle.

8. Hand start all the frame bolts while aligning the frame to the paint marks.

9. Tighten the frame bolts.

Tighten the frame bolts to 100 N.m (74 lb ft) plus 180 degrees.

10. Remove the lift table.

11. Connect the drive axles to the steering knuckles.

12. Connect the lower control arm to the steering knuckle.

13. Connect the intermediate steering shaft to the steering gear.

14. Connect the outer tie rod ends to the steering knuckles.

15. Connect the stabilizer links to the stabilizer bar.

16. Install the left transmission mount.

17. Install the engine mount.

18. Remove the wood blocks between the powertrain and frame.

19. Connect the transmission shift cable to the transmission.

20. Connect the exhaust takedown pipe to the exhaust manifold.

Tighten the nuts to 30 N.m (22 lb ft).

21. Connect the generator harness connectors.

Tighten the generator terminal nut to 20 N.m (15 lb ft).

22. Connect the starter harness connectors (3, 4, 5).

* Tighten the battery terminal nut to 17 N.m (13 lb ft).

* Tighten the S-terminal nut to 3 N.m (27 lb in).

23. Install the compressor and condenser hose assembly to the compressor.

24. Evacuate and charge the refrigerant system. Refer to Refrigerant Recovery and Recharging.

25. Install the engine drive belt.

26 Connect the following harness connectors:

* TMAP sensor

* ETC

* MAP sensor

* Crankshaft sensor

* Oil pressure sensor

* Purge solenoid

* BARO sensor

* Ignition coil modules

* O2 sensor

* Vehicle speed sensor

* Engine temperature sensor

* Boost solenoid

27. Install the inlet heater hose (1) and outlet heater hose (2).

28. Install the radiator outlet hose.

29. Connect the fuel line to the fuel rail.

30. Install the surge tank to the cylinder head pipe.

Tighten the bolt to 10 N.m (89 lb in).

31. Release the cooling module from the upper body structure.

32. Install the air outlet duct.

33. Connect the negative battery cable.

34 Fill the engine with engine oil to the proper level. Refer to Fluid and Lubricant Recommendations.

35 Fill the cooling system. Refer to Draining and Filling Cooling System (2.0L (LSJ)) Draining and Filling Cooling System (2.2L (L61), 2.4L (LE5)) Draining and Filling Cooling System (GE 47716 Fill).

36 Road test the vehicle.