|

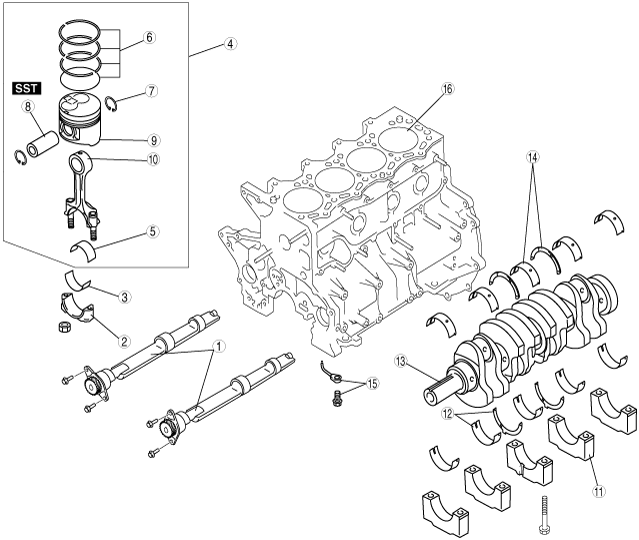

CYLINDER BLOCK DISASSEMBLY (III) [WLT-1, WLT-2, WL-3]

id011097500800

1. Disassemble in the order shown in the figure.

bwl1ge00000276

|

|

1

|

Balance shaft (If equipped)

|

|

2

|

Connecting rod cap

|

|

3

|

Lower connecting rod bearing

|

|

4

|

Piston, connecting rod

|

|

5

|

Upper connecting rod bearing

|

|

6

|

Piston ring

|

|

7

|

Piston pin clip

|

|

8

|

Piston pin

(See Piston Pin Disassembly Note .)

|

|

9

|

Piston

|

|

10

|

Connecting rod

|

|

11

|

Main bearing cap

|

|

12

|

Lower main bearing, lower thrust bearing

|

|

13

|

Crankshaft

(See Crankshaft Disassembly Note.)

|

|

14

|

Upper main bearing, upper thrust bearing

|

|

15

|

Oil jet valve, nozzle

|

|

16

|

cylinder block

|

Connecting Rod Cap Disassembly Note

1. Before removing the connecting rod cap, inspect the connecting rod side clearance. (See CONNECTING ROD INSPECTION [WLT-1, WLT-2, WL-3].)

Piston, Connecting Rod Disassembly Note

1. Before removing the piston and connecting rod, inspect the connecting rod oil clearance. (See CONNECTING ROD SIDE CLEARANCE INSPECTION [WLT-1, WLT-2, WL-3].)

2. Inspect the oscillation torque. (See PISTON AND CONNECTING ROD INSPECTION [WLT-1, WLT-2, WL-3].)

Piston Pin Disassembly Note

1. Remove the piston pin using the SST.

bwl1ge00000005

|

Main Bearing Cap Disassembly Note

1. Before removing the main bearing cap, inspect the crankshaft end play. (See CRANKSHAFT END PLAY INSPECTION/REPAIR [WLT-1, WLT-2, WL-3].)

2. Loosen the main bearing cap bolts in two or three steps in the order shown in the figure.

bwl1ge00000006

|

Crankshaft Disassembly Note

1. Before removing the crankshaft, inspect the main journal oil clearance. (See CRANKSHAFT OIL CLEARANCE INSPECTION/REPAIR [WLT-1, WLT-2, WL-3].)