|

CYLINDER HEAD GASKET REPLACEMENT [SKYACTIV-G 2.5]

id0110s6800700

Replacement Part

|

O-ring

Quantity: 1

Location of use: Water inlet pipe

|

Gasket

Quantity: 1

Location of use: Water inlet pipe

|

Cylinder head gasket

Quantity: 1

Location of use: Cylinder head

|

Oil and Chemical Type

|

Engine oil

Type: Recommended oil

|

Gear oil

Type: SAE 90 gear oil or equivalent

|

Sealant

Type: LOCTITE 962T, 518, 272 or equivalent

|

|

Silicone sealant

Type: TB1217D or equivalent

|

Coolant

Type: Recommended coolant

|

—

|

1. Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

2. Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

3. Remove the ignition coil/ion sensors. (See IGNITION COIL/ION SENSOR REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

4. Remove the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

5. Remove the front splash shield (RH). (See SPLASH SHIELD REMOVAL/INSTALLATION.)

6. Remove the drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

7. Drain the engine oil. (See ENGINE OIL REPLACEMENT [SKYACTIV-G 2.5].)

8. Drain the engine coolant. (See ENGINE COOLANT REPLACEMENT [SKYACTIV-G 2.5].)

9. Remove the intake manifold. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

10. Set aside the exhaust manifold to the vehicle rear. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

11. Remove the vacuum pump. (See VACUUM PUMP REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

12. Remove the high pressure fuel pump and rear housing. (See HIGH PRESSURE FUEL PUMP REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

13. Disconnect the heater hoses from the engine coolant control valve and the flange.

14. Removal the coolant control valve. (See COOLANT CONTROL VALVE REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

15. Remove the oil pan. (See OIL PAN REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

16. Remove the timing chain and chain guide. (See TIMING CHAIN REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

17. Remove the OCV. (See OIL CONTROL VALVE (OCV) REMOVAL/INSTALLATION [SKYACTIV-G 2.5].)

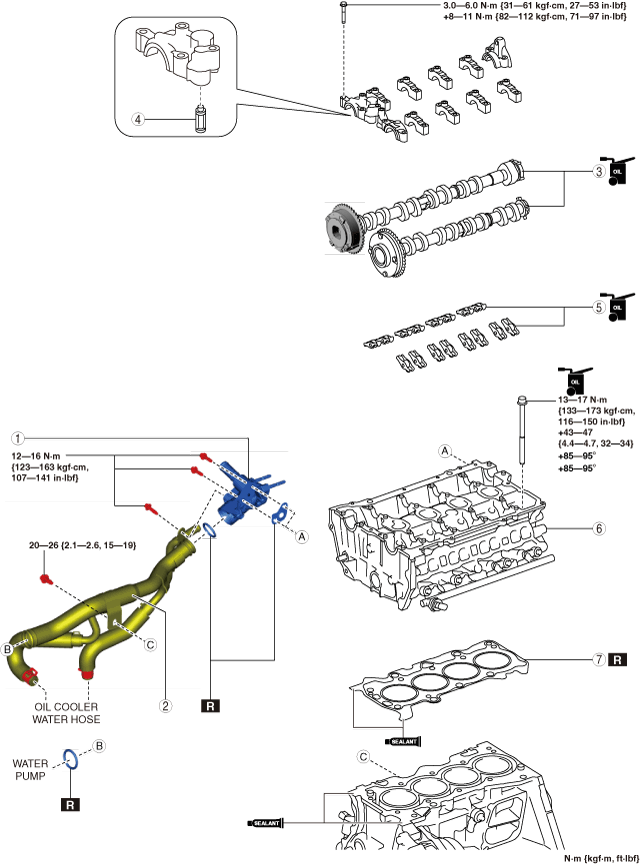

18. Remove in the order indicated in the table.

19. Install in the reverse order of removal.

20. Refill with the specified type and amount of the engine oil. (See ENGINE OIL REPLACEMENT [SKYACTIV-G 2.5].)

21. Refill the engine coolant. (See ENGINE COOLANT REPLACEMENT [SKYACTIV-G 2.5].)

22. Start the engine, and inspect and adjust the following:

ac8wzw00003747

|

|

1

|

Flange

|

|

2

|

Water inlet pipe

|

|

3

|

Camshaft

(See Camshaft Removal Note.)

(See Camshaft Installation Note.)

|

|

4

|

OCV oil filter

|

|

5

|

Rocker arm

(See Rocker Arm Removal Note.)

(See Rocker Arm Installation Note.)

|

|

6

|

Cylinder head

(See Cylinder Head Removal Note.)

|

|

7

|

Cylinder head gasket

|

Camshaft Removal Note

1. Loosen the camshaft cap installation bolts in a few passes in the order shown in the figure and remove the camshaft caps.

am6zzw00011874

|

2. Remove the camshafts.

Rocker Arm Removal Note

1. Keep the rocker arms in the order of removal to enable reassembly in their original positions.

Cylinder Head Removal Note

1. Temporarily install the oil pan to support the engine from under the vehicle.

2. Support the engine (oil pan) using a commercially available engine lifter or garage jack.

ac5uuw00006911

|

3. Remove the chain on the SST that suspended the engine and set it aside.

4. Loosen the cylinder head installation bolts in two or three passes in the order shown in the figure and remove them.

am3uuw00008817

|

5. Remove the cylinder head.

Cylinder Head Installation Note

1. Measure the length of the cylinder head bolt.

amxzzw00003984

|

2. When a cylinder head bolt is reused, apply engine oil to any part of the following:

3. Completely remove any oil, dirt, and silicone sealant adhering to the cylinder block.

4. Apply silicone sealant (TB1217D or equivalent) to the areas shown in the figure.

am3zzw00019917

|

5. Install a new cylinder head gasket to the cylinder block.

6. Apply silicone sealant (TB1217D or equivalent) to the areas shown in the figure.

am3zzw00019920

|

7. Set the cylinder head on the cylinder block.

8. Tighten the cylinder head bolts in the order shown in the following 4 steps.

am3uuw00008818

|

9. Install the chain for the SST which was set aside and secure the engine.

10. Remove the engine lifter or garage jack.

11. Remove the temporarily assembled oil pan.

Rocker Arm Installation Note

1. Apply engine oil to the HLAs and the end of the valve stems.

am3uuw00008819

|

2. Install the rocker arms to the same positions as before removal.

Camshaft Installation Note

1. Apply SAE 90 gear oil or equivalent, or engine oil to the positions shown in the figure.

am2zzw00011199

|

2. Apply gear oil (SAE 90 or equivalent) or engine oil to the thrust surface (both surfaces front and back) of the front journal on each camshaft.

3. Install the camshafts with cylinder No.1 cam aligned to the TDC position as shown in the figure.

ac8wzw00003748

|

4. Apply SAE 90 gear oil or equivalent, or engine oil to the central area of each journal on the camshaft.

am6zzw00011876

|

5. Apply SAE 90 gear oil or equivalent, or engine oil to the thrust surface of the front camshaft cap.

6. Apply sealant (LOCTITE 962T, 518, 272 or equivalent) to the rear camshaft cap installation area on the exhaust side of the cylinder head or the rear camshaft cap on the exhaust side.

am2zzw00011072

|

7. Install the camshaft caps in the marked number order, and temporarily tighten the camshaft cap installation bolts in two or three passes evenly.

8. Tighten the camshaft cap installation bolts in two steps in the order shown in the figure.

am3uuw00008824

|

Water Inlet Pipe and Flange Installation Note

1. Apply engine coolant to a new O-ring (water pump side).

2. Install the O-ring to the water inlet pipe.

ac5wzw00012140

|

3. Insert the water inlet pipe into the water pump so that the marked position is aligned with the projection position.

ac5wzw00012141

|

4. Temporarily tighten the bolt shown in the figure.

ac8wzw00003749

|

5. Apply engine coolant to a new O-ring (flange side).

6. Install the O-ring to the water inlet pipe.

ac5wzw00012143

|

7. Assemble the flange, gasket and bolts.

ac5wzw00012144

|

8. Assemble the water inlet pipe and the flange so that the marked position is aligned with the projection position.

ac5wzw00012145

|

9. Temporarily tighten the bolt shown in the figure.

ac5wzw00012146

|

10. Tighten the bolts shown in the figure.

ac8wzw00003750

|

11. Tighten the bolt shown in the figure. (With oil cooler)

ac5wzw00012148

|