|

CONVERTER HOUSING REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL]

id0517k3332500

1. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [AY6A-EL, AY6AX-EL].)

2. Remove the transaxle. (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

3. Clean the transaxle. (See AUTOMATIC TRANSAXLE CLEANING [AY6A-EL, AY6AX-EL].)

4. Remove the torque converter. (See AUTOMATIC TRANSAXLE CLEANING [AY6A-EL, AY6AX-EL].)

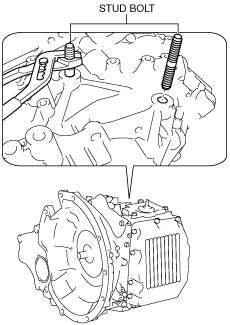

5. Remove the stud bolts.

ac9uuw00004144

|

6. Set the SSTs as shown in the figure.

ac9wzw00002030

|

7. Install the transaxle to the SSTs.

ac9wzw00002032

|

8. Remove the oil pipe component and the O-rings.

ac9uuw00004145

|

9. Refer to the “AUTOMATIC TRANSAXLE DISASSEMBLY/ASSEMBLY PRECAUTION” before disassembling/assembling the transaxle. (See AUTOMATIC TRANSAXLE DISASSEMBLY/ASSEMBLY PRECAUTION [AY6A-EL, AY6AX-EL].)

10. Remove the bolts as shown in the figure.

am6xuw00004221

|

11. Using a plastic hammer, tap the converter housing to remove it.

am6xuw00004222

|

12. Remove the case gaskets as shown in the figure.

ac9uuw00004037

|

13. Remove the gaskets as shown in the figure.

am6xuw00004224

|

14. Clean the contact surface of the transaxle case and the converter housing and the bolt holes.

15. Install the gaskets as shown in the figure.

am6xuw00004224

|

16. Install the case gaskets as shown in the figure.

ac9uuw00004037

|

17. Apply sealant to the converter housing as shown in the figure.

am6xuw00004225

|

18. Install the converter housing before the applied sealant starts to harden.

am6xuw00004226

|

19. Temporarily tighten the bolts by hand as shown in the figure.

am6xuw00004381

|

|

Bolt number |

Bolt size |

Length (measured from below the head) (mm {in}) |

|---|---|---|

|

A

|

M8 × 1.25

|

30 {1.2}

|

|

B

|

M8 × 1.25

|

35 {1.4}

|

|

C

|

M8 × 1.25

|

39 {1.5}

|

|

D

|

M10 × 1.25

|

28 {1.1}

|

|

E

|

M10 × 1.25

|

43 {1.7}

|

20. Tighten the bolts.

21. Install the oil pipe component and new O-rings.

ac9uuw00004145

|

22. Remove the transaxle from the SSTs.

ac9wzw00002031

|

23. Install the stud bolts using double nutted.

ac9uuw00003997

|

24. Remove the double nutted from the stud bolts.

25. Install the torque converter. (See TORQUE CONVERTER REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

26. Install the transaxle. (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [AY6A-EL, AY6AX-EL].)

27. Add ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) LEVEL ADJUSTMENT [AY6A-EL, AY6AX-EL].)

28. Adjust the ATF level. (See AUTOMATIC TRANSAXLE FLUID (ATF) LEVEL ADJUSTMENT [AY6A-EL, AY6AX-EL].)

29. Perform the “MECHANICAL SYSTEM TEST”. (See MECHANICAL SYSTEM TEST [AY6A-EL, AY6AX-EL].)