|

CYLINDER HEAD GASKET REPLACEMENT [MZI-3.7]

id0110c5800700

1. Drain the engine oil. (See ENGINE OIL REPLACEMENT [MZI-3.7].)

2. Remove the engine and transaxle component. (See ENGINE REMOVAL/INSTALLATION [MZI-3.7].)

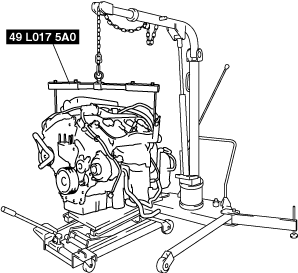

3. Secure the engine and transaxle component using a hoist and the SST.

ac9wzw00002263

|

4. Remove the dynamic chamber and throttle body as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

5. Remove the fuel injector and fuel distributor together as a single unit. (See FUEL INJECTOR REMOVAL/INSTALLATION [MZI-3.7].)

6. Remove the thermostat and thermostat housing together as a single unit. (See THERMOSTAT REMOVAL/INSTALLATION [MZI-3.7].)

7. Remove the Intake manifold. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

8. Remove both WU-TWCs together with both exhaust manifolds as a single unit. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [MZI-3.7].)

9. Remove the ignition coils. (See IGNITION COIL REMOVAL/INSTALLATION [MZI-3.7].)

10. Remove the dipstick.

11. Remove the power steering oil pump drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [MZI-3.7].)

12. Remove the power steering oil pump. (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [L.H.D.].)(See POWER STEERING OIL PUMP REMOVAL/INSTALLATION [R.H.D.].)

13. Remove the generator. (See GENERATOR REMOVAL/INSTALLATION [MZI-3.7].)

14. Remove the OCV component (LH) (RH). (See TIMING CHAIN REMOVAL/INSTALLATION [MZI-3.7].)

15. Remove in the order indicated in the table.

16. Install in the reverse order of removal.

17. Start the engine and:

18. Perform a road test.

ac9wzw00003268

|

|

1

|

Timing chain component

|

|

2

|

Camshaft cap (LH)

|

|

3

|

Camshaft timing chain tensioner (LH)

|

|

4

|

Camshaft timing chain (LH)

|

|

5

|

Camshaft component (LH)

|

|

6

|

Camshaft cap (RH)

|

|

7

|

Camshaft timing chain tensioner (RH)

|

|

8

|

Camshaft timing chain (RH)

|

|

9

|

Camshaft component (RH)

|

|

10

|

Cylinder head (LH)

(See Cylinder Head Removal Note.)

|

|

11

|

Cylinder head gasket (LH)

|

|

12

|

Cylinder head (RH)

(See Cylinder Head Removal Note.)

|

|

13

|

Cylinder head gasket (RH)

|

Timing chain Component Removal Note

1. Turn the crankshaft clockwise so that the crankshaft keyway is in the 11 o’clock position. (This will position the No.1 cylinder at TDC.)

ac9wzw00002265

|

2. Mark the timing chain at the position of each timing sprocket timing mark.

azzjjw00000157

|

3. Mark the camshaft timing chain at the positions where it is aligned with each of the camshaft sprocket on both banks.

LH

ac9wzw00002267

|

RH

ac9wzw00002268

|

4. Remove the timing chain in the following order.

ac9wzw00002269

|

Camshaft Component Removal Note

1. Rotate the crankshaft counterclockwise until the keyway is in the 9 o'clock position.

ac9wzw00002270

|

2. Slowly compress the camshaft timing chain tensioner (LH) piston by hand.

3. Insert an approx. 1.0 mm {0.039 in} thin wire or paper clip into the camshaft timing chain tensioner (LH) shown in the figure to hold the tensioner piston.

ac9wzw00002271

|

4. Verify that the camshafts (LH) are in the neutral position.

ac9wzw00002272

|

5. Loosen the LH bank camshaft cap bolts in several passes in the order shown in the figure and remove the camshaft cap.

ac9wzw00002273

|

6. Remove the camshaft, camshaft sprocket, camshaft timing chain, and camshaft timing chain tensioner of the LH bank as a single unit.

7. Slowly compress the camshaft timing chain tensioner (RH) piston by hand.

8. Insert an approx. 1.0 mm {0.039 in} thin wire or paper clip into the camshaft timing chain tensioner (RH) shown in the figure to hold the tensioner piston.

ac9wzw00002274

|

9. Put a wrench to the position shown in the figure on the RH bank camshaft, rotate the RH bank camshaft counterclockwise, and set the camshaft to the neutral position.

ac9wzw00002275

|

ac9wzw00002276

|

10. Loosen the RH bank camshaft cap bolts in several passes in the order shown in the figure and remove the camshaft cap.

ac9wzw00002277

|

11. Remove the camshaft, camshaft sprocket, camshaft timing chain, and camshaft timing chain tensioner of the RH bank as a single unit.

Cylinder Head Removal Note

1. Loosen the cylinder head bolts in several passes in the order shown.

ac9wzw00002278

|

Cylinder Head Installation Note

1. Tighten the cylinder head bolts in the order in 6 steps in the order shown in the figure.

ac9wzw00002279

|

Tightening torque

|

Step |

Installation position |

Tightening torque |

|---|---|---|

|

1

|

1—16

|

20 N·m {2.0 kgf·m, 15 ft·lbf}

|

|

2

|

1—16

|

35 N·m {3.6 kgf·m, 26 ft·lbf}

|

|

3

|

1—16

|

90 °

|

|

4

|

1—16

|

90 °

|

|

5

|

1—16

|

90 °

|

|

6

|

17, 18

|

8.5—11.5 N·m {87—117 kgf·cm, 76—101 in·lbf}

|

Camshaft Component Installation Note

1. Assemble the camshaft timing chain tensioners on both sides.

2. Install the camshaft component (RH).

RH

ac9wzw00005858

|

ac9wzw00002276

|

ac9wzw00003269

|

ac9wzw00002282

|

ac9wzw00003273

|

ac9wzw00002284

|

ac9wzw00005859

|

3. Install the camshaft component (LH).

LH

ac9wzw00002286

|

ac9wzw00002272

|

ac9uuw00000619

|

ac9wzw00002287

|

4. Turn the crankshaft clockwise so that the crankshaft keyway is in the 11 o’clock position. (This will position the No.1 cylinder at TDC.)

ac9wzw00002288

|

Timing chain Component Installation Note

1. Follow the “TIMING CHAIN REMOVAL/INSTALLATION” procedure and install the timing chain. (See TIMING CHAIN REMOVAL/INSTALLATION [MZI-3.7].)