|

1

|

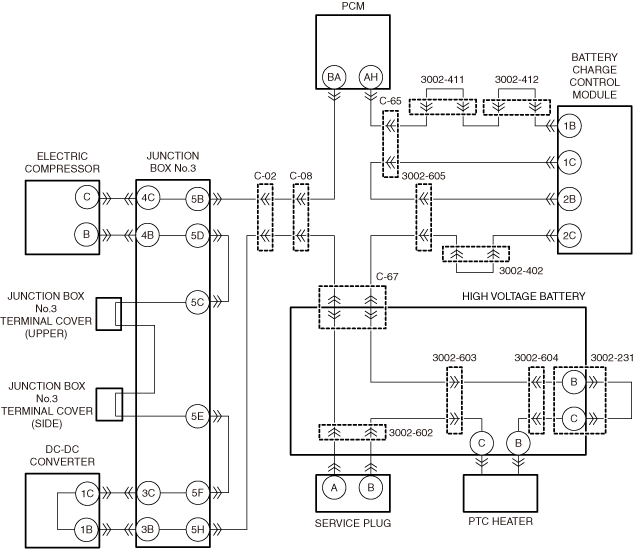

DETERMINE OPEN CIRCUIT LOCATION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

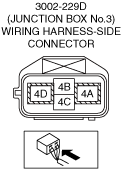

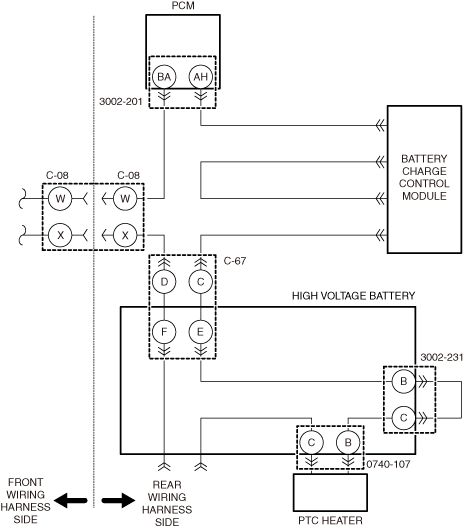

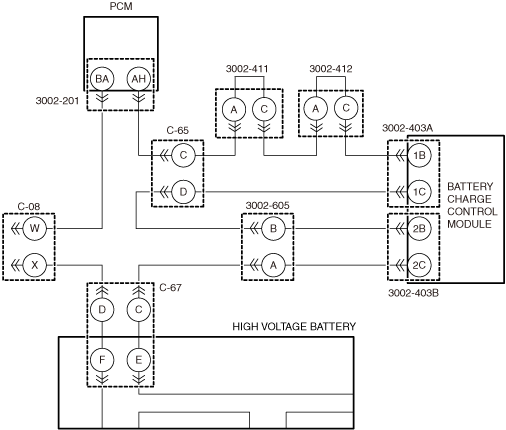

• Verify that jumper wires are installed between the following connector terminals.

-

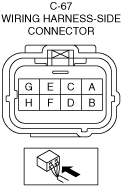

― Connector C-67 (vehicle wiring harness side)

-

• Terminal D and terminal C

-

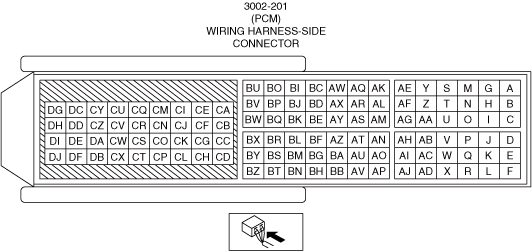

― Connector 3002-201 (vehicle wiring harness side)

-

• Terminal BA and terminal AH

• Install the jumper wire between the following connector terminals to short them with each other.

-

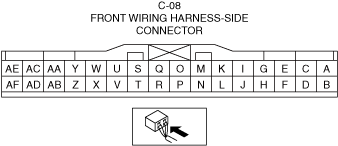

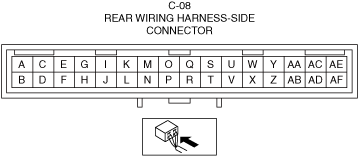

― C-08 (rear wiring harness side)

-

• Terminal W and terminal X

-

Caution

-

• When using the jumper wire, be careful not to short wrong terminals. Otherwise, a vehicle malfunction could occur.

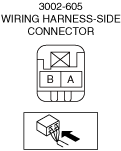

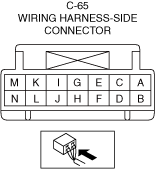

• Disconnect connector C-65 (vehicle wiring harness side) and 3002-605 (vehicle wiring harness side)

• Inspect for continuity between the following terminals of connector.

-

― Connector C-65 (vehicle wiring harness side)

-

• Terminal C

-

― Connector 3002-605 (vehicle wiring harness side

-

• Terminal A

• Is there continuity?

|

Yes

|

Go to step 6.

|

|

No

|

Go to the next step.

|

|

2

|

INSPECT WIRING HARNESS BETWEEN CONNECTOR C-08 AND CONNECTOR 3002-201 FOR OPEN CIRCUIT

• Remove the jumper wire installed to connector 3002-201.

• Inspect for continuity between the following terminals of connector.

-

― C-08 (vehicle wiring harness side)

-

• Terminal W

― 3002-201 (vehicle wiring harness side)

-

• Terminal BA

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

3

|

INSPECT WIRING HARNESS BETWEEN CONNECTOR C-65 AND CONNECTOR 3002-201 FOR OPEN CIRCUIT

• Remove the jumper wire installed to connector 3002-201.

• Inspect for continuity between the following terminals of connector.

-

― C-65 (vehicle wiring harness side)

-

• Terminal C

― 3002-201 (vehicle wiring harness side)

-

• Terminal AH

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

4

|

INSPECT WIRING HARNESS BETWEEN CONNECTOR C-08 AND CONNECTOR C-67 FOR OPEN CIRCUIT

• Remove the jumper wire installed to connector C-08.

• Inspect for continuity between the following terminals of connector.

-

― C-08 (vehicle wiring harness side)

-

• Terminal X

― C-67 (vehicle wiring harness side)

-

• Terminal D

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the wiring harness between connector C-08 and connector C-67.

Perform the repair completion verification 1.

|

|

5

|

INSPECT WIRING HARNESS BETWEEN CONNECTOR C-65 AND CONNECTOR 3002-605 FOR OPEN CIRCUIT

• Inspect for continuity between the following terminals of connector.

-

― C-65 (vehicle wiring harness side)

-

• Terminal D

― 3002-605 (vehicle wiring harness side)

-

• Terminal B

• Is there continuity?

|

Yes

|

Replace the wiring harness between connector C-67 and connector 3002-605.

Perform the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

6

|

INSPECT WIRING HARNESS BETWEEN CONNECTOR C-65 AND CONNECTOR 3002-403A FOR OPEN CIRCUIT

• Inspect for continuity between the following terminals of connector.

-

― C-65 (charge lid box assembly side)

-

• Terminal C and terminal D

• Is there continuity?

|

Yes

|

Go to step 11.

|

|

No

|

Go to the next step.

|

|

7

|

INSPECT INTERLOCK CIRCUIT IN ONBOARD CHARGER FOR OPEN CIRCUIT

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

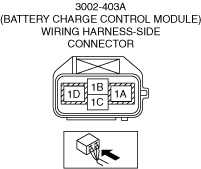

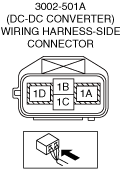

• Disconnect connector 3002-403A.

• Install the jumper wire between the following connector terminals to short them with each other.

-

― Connector 3002-403A (vehicle wiring harness side)

-

• Terminal 1B and terminal 1C

-

Caution

-

• When using the jumper wire, be careful not to short wrong terminals. Otherwise, a vehicle malfunction could occur.

• Inspect for continuity between the following terminals of connector.

-

― C-65 (charge lid box assembly side)

-

• Terminal C and terminal D

• Is there continuity?

|

Yes

|

Replace the onboard charger, then go to the repair completion verification 1.

|

|

No

|

Go to the next step.

|

|

8

|

INSPECT WIRING HARNESS BETWEEN CONNECTOR C-65 AND CONNECTOR 3002-403A FOR OPEN CIRCUIT

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Remove the jumper wire installed to connector 3002-403A.

• Inspect for continuity between the following terminals of connector.

-

― C-65 (onboard charger side)

-

• Terminal D

-

― Connector 3002-403A (vehicle wiring harness side)

-

• Terminal 1C

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

9

|

INSPECT 3002-411 CONNECTOR INTERNAL CIRCUIT FOR OPEN CIRCUIT

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Disconnect connector 3002-411.

• Inspect for continuity between the following terminals of connector.

-

― 3002-411 (high voltage battery side)

-

• Terminal A and terminal C

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the high voltage battery, then go to the repair completion verification 1.

|

|

10

|

INSPECT 3002-412 CONNECTOR INTERNAL CIRCUIT FOR OPEN CIRCUIT

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Disconnect connector 3002-412.

• Inspect for continuity between the following terminals of connector.

-

― 3002-412 (high voltage battery side)

-

• Terminal A and terminal C

• Is there continuity?

|

Yes

|

Replace the charge port assembly, then go to the repair completion verification 1.

|

|

No

|

Replace the high voltage battery, then go to the repair completion verification 1.

|

|

11

|

INSPECT WIRING HARNESS BETWEEN CONNECTOR 3002-605 AND CONNECTOR 3002-403B FOR OPEN CIRCUIT

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

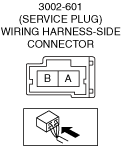

• Disconnect connector 3002-605.

• Inspect for continuity between the following terminals of connector.

-

― Connector 3002-605 (charge lid box assembly side)

-

• Terminal A and terminal B

• Is there continuity?

|

Yes

|

Go to step 13.

|

|

No

|

Go to the next step.

|

|

12

|

INSPECT INTERLOCK CIRCUIT IN ONBOARD CHARGER FOR OPEN CIRCUIT

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

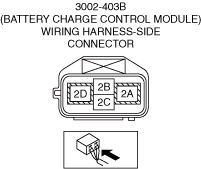

• Disconnect connector 3002-403B.

• Install the jumper wire between the following connector terminals to short them with each other.

-

― Connector 3002-403B (vehicle wiring harness side)

-

• Terminal 2B and terminal 2C

-

Caution

-

• When using the jumper wire, be careful not to short wrong terminals. Otherwise, a vehicle malfunction could occur.

• Inspect for continuity between the following terminals of connector.

-

― Connector 3002-605 (charge lid box assembly side)

-

• Terminal A and terminal B

• Is there continuity?

|

Yes

|

Replace the onboard charger, then go to the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

13

|

VERIFY IF CAUSE IS OPEN CIRCUIT IN PCM INTERNAL CIRCUIT

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power OFF and wait for 30 s or more.

• Switch the main power ON (READY on) and wait for 60 s or more.

• Perform the DTC inspection for the PCM.

• Is DTC P0A0D:00 a present malfunction?

|

Yes

|

Replace the high voltage battery, then go to the repair completion verification 1.

|

|

No

|

Go to the repair completion verification 2.

|