|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the snapshot data.

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

|

—

|

Go to the next step.

|

|

2

|

VERIFY DRIVE MOTOR CONTROL MODULE DTCs

• Perform the DTC inspection for the drive motor control module.

• Is DTC P0A78:00 a present malfunction?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

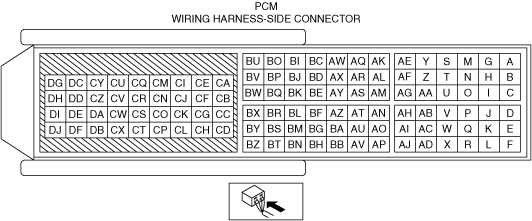

INSPECT PCM CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

4

|

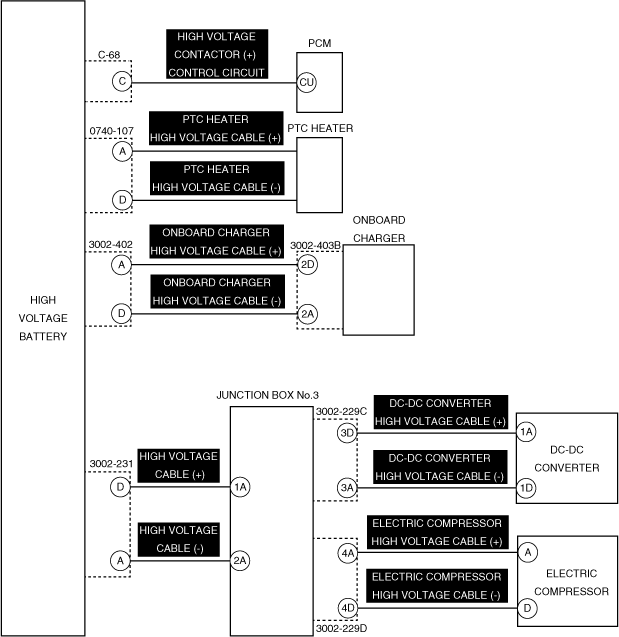

INSPECT COMMON CONNECTOR (C-68) FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

If there is a malfunction with common connector (C-68) (high voltage battery side):

• Replace the high voltage battery, then go to the repair completion verification 1.

If there is a malfunction with common connector (C-68) (vehicle wiring harness side):

• Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

5

|

INSPECT HIGH VOLTAGE CONTACTOR (+) CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

6

|

INSPECT HIGH VOLTAGE CONTACTOR (+) CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

7

|

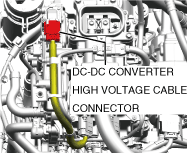

INSPECT DC-DC CONVERTER HIGH VOLTAGE CABLE (+) FOR OPEN CIRCUIT

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Remove the service plug.

• After 10 min have elapsed after removing the service plug, perform a zero voltage verification at the voltage detection point of the junction box to verify that there is no electrical charge in the high voltage circuit.

• Disconnect the following high voltage cable connectors.

-

― DC-DC converter high voltage cable connector (DC-DC converter side)

|

Yes

|

Go to the next step.

|

|

No

|

Wear insulating gloves, replace the DC-DC converter high voltage cable, and then perform the repair completion verification.

|

|

8

|

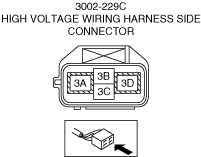

VERIFY IF MALFUNCTION IS CAUSED BY SHORT CIRCUIT IN HIGH VOLTAGE CABLE BETWEEN JUNCTION BOX NO.3 AND DC-DC CONVERTER

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the following connectors are disconnected.

-

― DC-DC converter high voltage cable connector (DC-DC converter side)

-

Warning

-

<<High voltage>>

• For the insulation resistance tester usage, refer to the insulation resistance tester instruction manual. Otherwise, electrocution could result from the voltage generated by the insulation resistance tester.

-

Caution

-

<<High voltage>>

• Use an insulation resistance tester using a testing range of 500 V or less because the voltage applied by the insulation resistance tester may damage the parts.

|

Yes

|

Go to the next step.

|

| |

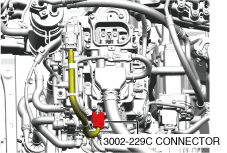

• Wear insulating gloves and measure the resistances between the following terminals using the insulation resistance tester (500 V range).

-

― 3002-229C connector (high voltage wiring harness side)

-

• Between terminal 3A and terminal 3D

• Is the measured value 100 MΩ or more?

|

No

|

Wear insulating gloves, replace the DC-DC converter high voltage cable, and then perform the repair completion verification.

|

|

9

|

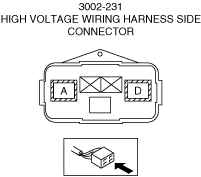

VERIFY IF MALFUNCTION IS CAUSED BY SHORT CIRCUIT IN HIGH VOLTAGE CABLE

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Disconnect both ends of the high voltage cable (junction box No.3 side and high voltage battery side).

-

Warning

-

<<High voltage>>

• For the insulation resistance tester usage, refer to the insulation resistance tester instruction manual. Otherwise, electrocution could result from the voltage generated by the insulation resistance tester.

-

Caution

-

<<High voltage>>

• Use an insulation resistance tester using a testing range of 500 V or less because the voltage applied by the insulation resistance tester may damage the parts.

• Wear insulating gloves and measure the resistances between the following terminals using the insulation resistance tester (500 V range).

-

― High voltage cable (junction box No.3 side)

-

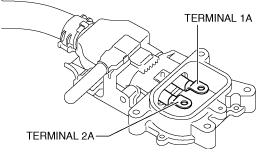

• Between terminal 1A and terminal 2A

• Is the measured value 100 MΩ or more?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the high voltage cable, then go to the repair completion verification 1.

|

|

10

|

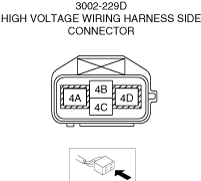

VERIFY IF MALFUNCTION IS CAUSED BY SHORT CIRCUIT IN HIGH VOLTAGE CABLE BETWEEN JUNCTION BOX NO.3 AND ELECTRIC COMPRESSOR

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Disconnect the following high voltage cable connectors.

-

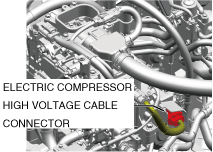

― Electric compressor high voltage cable connector

-

Warning

-

<<High voltage>>

• For the insulation resistance tester usage, refer to the insulation resistance tester instruction manual. Otherwise, electrocution could result from the voltage generated by the insulation resistance tester.

-

Caution

-

<<High voltage>>

• Use an insulation resistance tester using a testing range of 500 V or less because the voltage applied by the insulation resistance tester may damage the parts.

|

Yes

|

Go to the next step.

|

| |

• Wear insulating gloves and measure the resistances between the following terminals using the insulation resistance tester (500 V range).

-

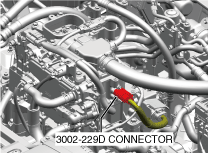

― 3002-229D connector (high voltage wiring harness side)

-

• Between terminal 4A and terminal 4D

• Is the measured value 100 MΩ or more?

|

No

|

Wear insulating gloves, replace the electric compressor high voltage cable, and then perform the repair completion verification.

|

|

11

|

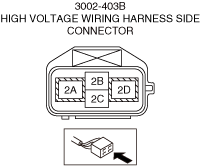

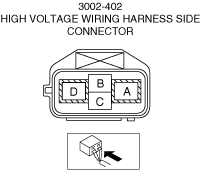

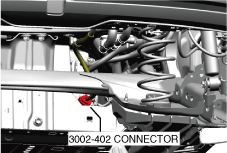

VERIFY IF MALFUNCTION IS CAUSED BY SHORT CIRCUIT IN WIRING HARNESS BETWEEN ONBOARD CHARGER AND CONNECTOR 3002-402

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Disconnect the following high voltage cable connectors.

-

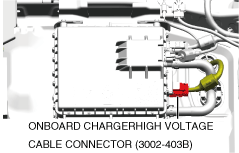

― Onboard charger high voltage cable connector (3002-403B)

• Disconnect the following connector.

-

Warning

-

<<High voltage>>

• For the insulation resistance tester usage, refer to the insulation resistance tester instruction manual. Otherwise, electrocution could result from the voltage generated by the insulation resistance tester.

-

Caution

-

<<High voltage>>

• Use an insulation resistance tester using a testing range of 500 V or less because the voltage applied by the insulation resistance tester may damage the parts.

|

Yes

|

Go to the next step.

|

| |

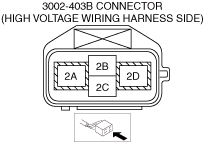

• Wear insulating gloves and measure the resistances between the following terminals using the insulation resistance tester (500 V range).

-

― 3002-403B connector (high voltage wiring harness side)

-

• Between terminal 2A and terminal 2D

• Is the measured value 100 MΩ or more?

|

No

|

Wear insulating gloves, replace the onboard charger high voltage wiring harness, and then perform the repair completion verification.

|

|

12

|

INSPECT JUNCTION BOX No.3 FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Perform [Insulation Resistance Inspection] for the junction box No.3 inspection.

• Is the insulation resistance within the standard?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the Junction box No.3, then go to repair completion verification 1.

|

|

13

|

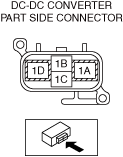

INSPECT DC-DC CONVERTER FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install the DC-DC converter high voltage wiring harness connector.

-

Caution

-

• Connect each probe of the circuit tester to the designated terminal. Resistance cannot be accurately measured if reversed.

• Connect the circuit tester probes to the following terminals and measure the resistance between the following terminals.

-

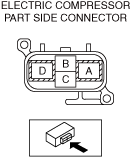

― DC-DC converter part side connector

-

• Terminal 1A: Voltage application side probe

• Terminal 1D: Ground side probe

• Is the resistance 1 MΩ or more?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the DC-DC converter, then go to repair completion verification 1.

|

|

14

|

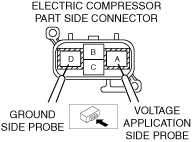

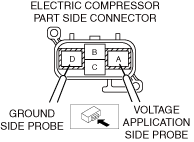

INSPECT ELECTRIC COMPRESSOR FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the electric compressor high voltage wiring harness connector is disconnected.

-

Caution

-

• Connect each probe of the circuit tester to the designated terminal. Resistance cannot be accurately measured if reversed.

• Connect the circuit tester probes to the following terminals and measure the voltage at the following terminals using diode measurement mode. The measurement is performed 2 times by changing the probe.

-

― Electric compressor part side connector

1st time

-

• Terminal A: Voltage application side probe

• Terminal D: Ground side probe

2nd time

-

• Terminal A: Ground side probe

• Terminal D: Voltage application side probe

• Are the measured values the following values?

-

― 1st measured value: No measured voltage (O.L. display)

― 2nd measured value: 0.39 — 0.73 V

|

Yes

|

Go to the next step.

|

|

No

|

Replace the electric compressor, then go to repair completion verification 1.

|

|

15

|

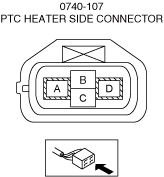

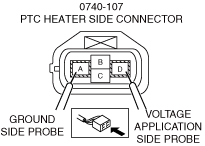

INSPECT PTC HEATER FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that connector 0740-107 is disconnected.

-

Caution

-

• Connect each probe of the circuit tester to the designated terminal. Resistance cannot be accurately measured if reversed.

• Connect the circuit tester probes to the following terminals and measure the resistance between the following terminals.

-

― Connector 0740-107 (vehicle wiring harness side)

-

• Terminal A: Voltage application side probe

• Terminal D: Ground side probe

• Is the resistance 1 MΩ or more?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the PTC heater, then go to repair completion verification 1.

|

|

16

|

INSPECT ONBOARD CHARGER FOR MALFUNCTION DEPENDING ON REPEATABILITY

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power OFF and wait for 30 s or more.

• Switch the main power ON (READY on) and wait for 60 s or more.

• Perform the DTC inspection for the PCM.

• Is DTC P0AA2:00 a present malfunction?

|

Yes

|

Replace the onboard charger, then go to the next step.

|

|

No

|

Go to repair completion verification 1.

|

|

17

|

INSPECT PCM FOR MALFUNCTION DEPENDING ON REPEATABILITY

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power OFF and wait for 30 s or more.

• Switch the main power ON (READY on) and wait for 60 s or more.

• Perform the DTC inspection for the PCM.

• Is DTC P0AA2:00 a present malfunction?

|

Yes

|

Replace the PCM, then go to the next step.

|

|

No

|

Go to repair completion verification 1.

|

|

18

|

INSPECT HIGH VOLTAGE BATTERY FOR MALFUNCTION DEPENDING ON REPEATABILITY

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power OFF and wait for 30 s or more.

• Switch the main power ON (READY on) and wait for 60 s or more.

• Perform the DTC inspection for the PCM.

• Is DTC P0AA2:00 a present malfunction?

|

Yes

|

Replace the high voltage battery, then go to the next step.

|

|

No

|

Go to repair completion verification 1.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Switch the main power OFF and wait for 30 s or more.

• Switch the main power ON (READY on) and wait for 60 s or more.

• Perform the DTC inspection for the PCM.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed

|