|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the snapshot data.

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

|

—

|

Go to the next step.

|

|

2

|

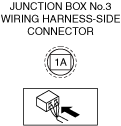

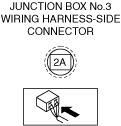

INSPECT JUNCTION BOX No.3 CONNECTOR FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Remove the service plug.

• After 10 min have elapsed after removing the service plug, perform a zero voltage verification at the voltage detection point of the junction box No.3 to verify that there is no electrical charge in the high voltage circuit.

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

3

|

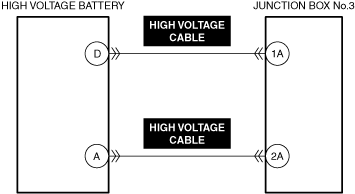

INSPECT THE CONNECTION CONDITION BETWEEN JUNCTION BOX No.3 AND THE HIGH VOLTAGE CABLES

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Inspect the tightening condition of the bolts between junction box No.3 and the high voltage cables.

• Is the tightening condition normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

4

|

INSPECT THE CONNECTION CONDITION BETWEEN HIGH VOLTAGE BATTERY AND THE HIGH VOLTAGE CABLES

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Inspect the connection condition between the high voltage battery and high voltage cables.

• Is the connection condition normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

5

|

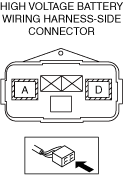

INSPECT HIGH VOLTAGE BATTERY CONNECTOR FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

6

|

INSPECT HIGH VOLTAGE CABLE FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

7

|

CHECK FOR SHORT TO GROUND AT BUS BAR BETWEEN INVERTER AND JUNCTION BOX NO.3

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Check for short to ground at the bus bar between the inverter and junction box No.3.

• Is the bus bar normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

8

|

CHECK CONNECTION CONDITIONS OF BUS BAR BETWEEN INVERTER AND JUNCTION BOX NO.3

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Check the connection conditions of the bus bar between the inverter and junction box No.3.

• Is the tightening condition normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

9

|

INSPECT JUNCTION BOX No.3 FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

10

|

INSPECT HIGH VOLTAGE BATTERY FOR MALFUNCTION DEPENDING ON REPEATABILITY

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Perform the DTC inspection for the drive motor control module.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, replace the high voltage battery, perform the repair completion verification 1.

|

|

No

|

Go to repair completion verification 2.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

-

Warning

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

-

― Drive the vehicle under the snapshot data condition.

• Perform the DTC inspection for the drive motor control module.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the drive motor control module, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 3

|

VERIFY THAT NO OTHER MALFUNCTION OCCURS

-

Warning

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• Drive the vehicle for 10 min or more.

• Perform the DTC inspection.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|