|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the snapshot data.

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

|

—

|

Go to the next step.

|

|

2

|

INSPECT FOR OTHER RELATED DTCs

• Perform the DTC inspection for the drive motor control module.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY PCM DTC

• Perform the DTC inspection for the PCM.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

4

|

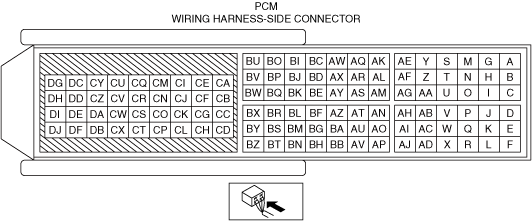

INSPECT PCM CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

5

|

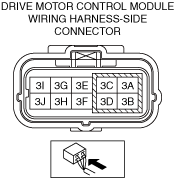

INSPECT DRIVE MOTOR CONTROL MODULE CONNECTOR FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Remove the service plug.

• After 10 min have elapsed after removing the service plug, perform a zero voltage verification at the voltage detection point of the junction box No.3 to verify that there is no electrical charge in the high voltage circuit.

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

6

|

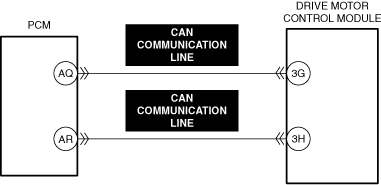

INSPECT DRIVE MOTOR CONTROL MODULE CAN COMMUNICATION LINE FOR SHORT OR OPEN CIRCUIT

• Inspect the applicable circuit for short and open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

-

― Switch the main power ON (READY on).

• Perform the DTC inspection for the drive motor control module.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the drive motor control module, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 3

|

VERIFY THAT NO OTHER MALFUNCTION OCCURS

-

Warning

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• Drive the vehicle for 10 min or more.

• Perform the DTC inspection.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|