|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the snapshot data.

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

|

—

|

Go to the next step.

|

|

2

|

DETERMINE IF MALFUNCTION IS ON CHARGING EQUIPMENT SIDE

• Perform quick charging using charging equipment other than that used when the DTC was output.

• Perform the DTC inspection for the battery charge control module.

• Is DTC P0D2A:00 displayed as a current malfunction?

-

Note

-

• If DTC P0D2A:00 is displayed as a past malfunction, a malfunction in the charging equipment used when the DTC was output can be considered.

|

Yes

|

Go to the next step.

|

|

No

|

The system is normal. (Explain to the customer that there is a possibility that a malfunction was detected due to a charging equipment malfunction.)

Go to the repair completion verification 2.

|

|

3

|

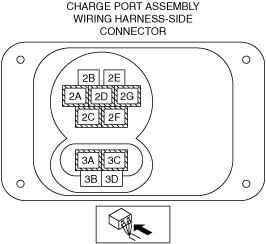

INSPECT CHARGE PORT ASSEMBLY CONNECTOR FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Remove the service plug.

• After 10 min have elapsed after removing the service plug, perform a zero voltage verification at the voltage detection point of the junction box No.3 to verify that there is no electrical charge in the high voltage circuit.

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the charge port assembly, then go to the repair completion verification 1.

|

|

4

|

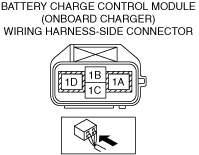

INSPECT BATTERY CHARGE CONTROL MODULE (ONBOARD CHARGER) CONNECTOR FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

5

|

INSPECT CHARGE PORT FOR MALFUNCTION

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Verify that the service plug is removed.

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the charge port assembry, then go to the repair completion verification 1.

|

|

6

|

INSPECT BATTERY CHARGE CONTROL MODULE (ONBOARD CHARGER) FOR MALFUNCTION DEPENDING ON REPEATABILITY

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Perform quick charging using charging equipment other than that used when the DTC was output.

• Perform the DTC inspection for the Battery charge control module.

• Is DTC P0D2A:00 displayed as a current malfunction?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the onboard charger, then go to the repair completion verification 2.

|

|

No

|

Go to the repair completion verification 2.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

-

Warning

-

<<High voltage>>

• Wear insulated gloves when working on a high voltage system.

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Perform quick charging using charging equipment other than that used when the DTC was output.

• Perform the DTC inspection for the Battery charge control module.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the onboard charger, then go to the next step.

|

|

No

|

Go to the next step.

|