|

am2zzn00003065

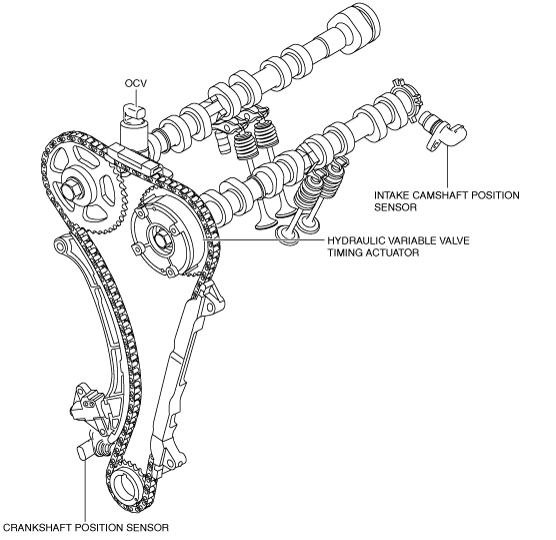

VARIABLE VALVE TIMING MECHANISM [SKYACTIV-G 1.3, SKYACTIV-G 1.5]

id0110q3002000

Without coolant control valve (4-1 exhaust system)

Outline

Structural View

am2zzn00003065

|

Structure

|

Part name

|

Function

|

|

Hydraulic variable valve timing actuator

|

|

|

OCV

|

|

|

Intake camshaft position sensor

|

|

|

Crankshaft position sensor

|

Operation

|

Mode |

OCV operation (spool valve) |

Hydraulic pressure |

Hydraulic variable valve timing actuator operation |

Valve timing |

|

|---|---|---|---|---|---|

|

Stopper pin |

Rotor |

||||

|

Fixed mode

|

Maximum retard position

|

To retard chamber

|

×

|

Maximum retard position

|

Maximum retard

|

|

Advance mode

|

To advance side

|

To advance chamber

|

—

|

Move to advance side

|

Advance

|

|

Retard mode

|

To retard side

|

To retard chamber

|

—

|

Move to retard side

|

Retard

|

|

Hold mode

|

Middle point

|

To advance/retard chamber

|

—

|

Hold at optimum position

|

Hold at optimum position

|

am2zzn00003066

|

am2zzn00003067

|

am2zzn00003068

|

am2zzn00003069

|