|

1

|

INSPECT IG1 RELAY

• Switch the ignition off.

• Disconnect the negative battery cable.

• Is the IG1 relay normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the IG1relay, then go to Step 10.

|

|

2

|

INSPECT PCM DTC

• Perform the PCM DTC inspection using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Without i-ELOOP:

• Go to Step 4.

With i-ELOOP:

• Go to the next step.

|

|

3

|

INSPECT DC-DC CONVERTER (i-ELOOP) DTC

• Perform the DC-DC converter (i-ELOOP) DTC inspection using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT BATTERY

• Is the battery normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace or charge the battery.

Then go to Step 10.

|

|

5

|

INSPECT GENERATOR

• Is the generator normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the generator.

Then go to the Step 10.

|

|

6

|

VERIFY SAS CONTROL MODULE CONNECTOR CONDITION

-

Warning

-

• Handling the component parts improperly can accidentally operate (deploy) the air bag modules, pre-tensioner seat belts and lap pre-tensioner seat belts, which may seriously injure you. Read the service warnings/cautions and the workshop manual before handling the air bag system components.

• Switch the ignition off.

• Disconnect the negative battery cable and wait for 1 min or more.

• Remove the column cover.

• Disconnect the clock spring connector.

• Remove the glove compartment.

• Disconnect the passenger-side air bag module connector.

• Disconnect the driver and passenger-side front seat connectors.

• Remove the B-pillar lower trim.

• Disconnect the driver and passenger-side front pre-tensioner seat belt connectors.

• Remove the trunk side trim. (with rear pre-tensioner seat belt)

• Disconnect the driver and passenger-side rear pre-tensioner seat belt connectors. (with rear pre-tensioner seat belt)

• Disconnect the driver and passenger-side curtain air bag module connectors.

• Disconnect the all SAS control module connectors.

• Inspect the connector and terminals (corrosion, damage, pin disconnection).

• Are the connector and terminals normal?

|

Yes

|

Without i-ELOOP:

• Go to the next step.

With i-ELOOP:

• Go to Step 8.

|

|

No

|

Replace the air bag harness.

After repair procedure, go to Step 10.

|

|

7

|

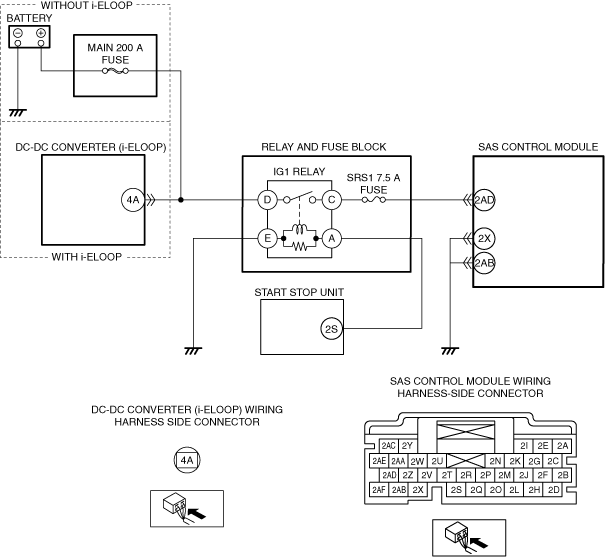

INSPECT SAS CONTROL MODULE POWER SUPPLY VOLTAGE

• SAS control module connectors are disconnected.

• Connect the negative battery cable.

• Switch the ignition on (engine off or on).

• Measure the voltage at the following terminal (wiring harness-side):

-

― SAS control module terminal 2AD

• Is the voltage 8.1—15.9?

|

Yes

|

Go to Step 9.

|

|

No

|

Inspect the SRS1 7.5 A fuse and MAIN 200 A fuse.

• If the fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between MAIN 200 A fuse and SAS control module terminal 2AD.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a short to ground.

-

― Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

• If the fuse is normal:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between battery positive terminal and SAS control module terminal 2AD.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

Go to Step 10.

|

|

8

|

INSPECT SAS CONTROL MODULE POWER SUPPLY VOLTAGE

• SAS control module connector is disconnected.

• Connect the negative battery cable.

• Switch the ignition on (engine off or on).

• Measure the voltage at the following terminal (wiring harness-side):

-

― SAS control module terminal 2AD

• Is the voltage 8.1—15.9?

|

Yes

|

Go to the next step.

|

|

No

|

Disconnect the service plug.

Inspect the SRS1 7.5 A fuse.

• If the fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between SRS1 7.5 A fuse and SAS control module terminal 2AD.

If there is a common connector:

-

• Determine the malfunctioning location by inspecting the common connector and terminals for corrosion, damage, or disconnection and by inspecting the DC-DC converter (i-ELOOP) terminal 4A-related wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which is shorted to ground, or the DC-DC converter (i-ELOOP) terminal 4A-related wiring harness.

-

― Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

• If the fuse is normal:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between DC-DC converter (i-ELOOP) terminal 4A and SAS control module terminal 2AD.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

Connect the service plug, then go to Step 10.

|

|

9

|

INSPECT SAS CONTROL MODULE BODY GROUND CIRCUIT FOR OPEN CIRCUIT

• SAS control module connectors are disconnected.

• Switch the ignition off.

• Disconnect the negative battery cable and wait 1 min or more.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

-

― SAS control module terminal 2X

― SAS control module terminal 2AB

-

Note

-

• Inspect for continuity while shaking the wiring harness between the SAS control module and body ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between SAS control module terminal and body ground.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Replace the malfunctioning part.

If there is no common connector:

• Replace the wiring harness which has an open circuit.

Go to the next step.

|

|

10

|

PERFORM SAS CONTROL MODULE DTC INSPECTION

• Connect the SAS control module connectors.

• Reconnect all disconnected connectors.

• Connect the negative battery cable.

• Switch the ignition ON (engine off or on).

• Clear the DTC for the SAS control module using the M-MDS.

• Perform the DTC inspection for the SAS control module using the M-MDS.

• Are the same DTCs present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the SAS control module.

|

|

No

|

DTC troubleshooting completed.

|