Step

Inspection

Action

1

VERIFICATION BEFORE SERVICING

• Are any DTCs, except the following, displayed?

-

― U0001:88― U0073:00

Yes

Determine the malfunctioning part.

No

Go to the next step.

2

INSPECT DTCs OUTPUT FROM CONNECTOR

• Inspect the terminal condition of the control module connector which output DTCs and the mid-connector.

• Are the connector terminals normal without damage, deformation, corrosion, or disconnection?

Yes

Go to the next step.

No

Repair or replace the connector, then go to Step 6.

3

INSPECT POWER SUPPLY OF CONTROL MODULE OUTPUTTING DTCs

• Refer to the terminal voltage table of the control module outputting DTCs and inspect the terminal voltage and fuse condition.

• Is the power supply normal?

Yes

Go to the next step.

No

Repair or replace the connector, then go to Step 6.

4

INSPECT BODY GROUND CONDITION OF CONTROL MODULE OUTPUTTING DTCs

• Inspect the body ground wires and ground point of the control module outputting DTCs.

• Are the ground and ground point normal?

Yes

Go to the next step.

No

Repair or replace the connector, then go to Step 6.

5

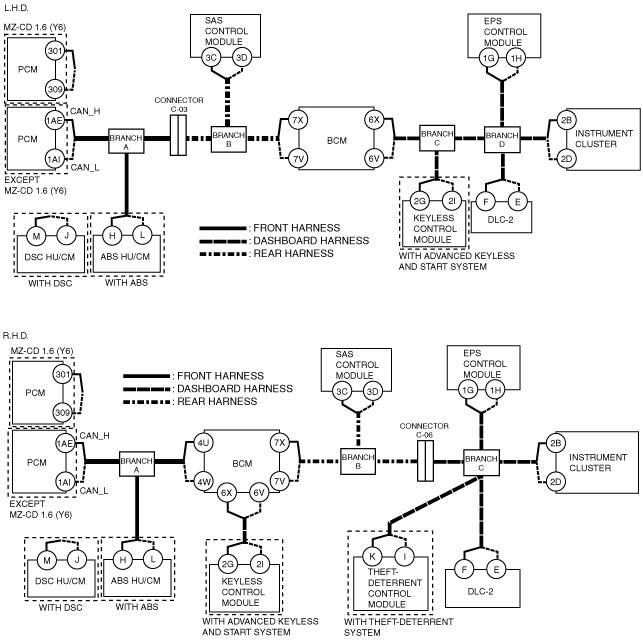

INSPECT CAN SYSTEM RELATED WIRING HARNESS

• Inspect the CAN system related wiring harness.

-

― Short to ground― Short to power supply― Short circuit between twisted pair wiring harnesses― Open circuit

• Is the wiring harness normal?

Yes

Go to the next step.

No

Repair or replace the wiring harness, then go to the next step.

6

INSPECT CAN-RELATED MODULES OTHER THAN BCM

• Remove only one of the CAN-related modules other than those related to the BCM.

• Clear DTCs using the M-MDS.

• Verify DTCs using the M-MDS.

• Is DTCs displayed?

-

― U0001:88― U0073:00

Yes

Install the removed, remove one of the other modules, then inspect all of the CAN-related modules using the same procedure.

After inspecting all of the modules, go to the next step.

No

Replace the removed module.

7

INSPECT DTCs

• Remove the BCM, then connect all of the modules.

• Clear DTCs using the M-MDS.

• Verify DTCs using the M-MDS.

• Is DTCs displayed?

-

― U0001:88― U0073:00

Yes

Return to Step 2.

No

Replace the BCM.