|

1

|

DETERMINE IF MALFUNCTION CAUSE IS i-stop SYSTEM OR A/C SYSTEM

• Verify the malfunction symptom.

• Does the malfunction occur only while the i-stop function is operating (engine stopped)?

|

Yes

|

Go to the next step.

|

|

No

|

Go to the applicable A/C malfunction diagnostic procedure.

|

|

2

|

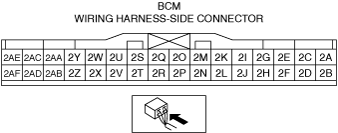

VERIFY DTC

• Perform the DTC inspection for the following modules.

-

― PCM

― Dash-electrical supply unit

― Body control module (BCM)

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

DETERMINE IF MALFUNCTION CAUSE IS AMBIENT TEMPERATURE SENSOR SIGNAL OR OTHER

• Switch the ignition ON (engine off).

• Compare the ambient temperature sensor on the multi-information display with the actual ambient temperature.

• Does the ambient temperature on the multi-information display correspond to the actual ambient temperature?

|

Yes

|

Full-auto air conditioner:

• Go to Step 6.

Manual air conditioner:

• Go to Step 9.

|

|

No

|

Go to the next step.

|

|

4

|

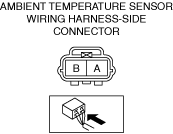

INSPECT AMBIENT TEMPERATURE SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

5

|

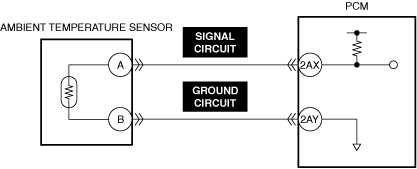

INSPECT AMBIENT TEMPERATURE SENSOR SIGNAL CIRCUIT AND GROUND CIRCUIT FOR SHORT CIRCUIT AND OPEN CIRCUIT

• Inspect the applicable circuit for a short circuit and open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

6

|

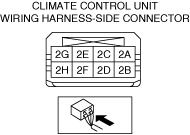

DETERMINE IF MALFUNCTION CAUSE IS PASSENGER COMPARTMENT TEMPERATURE SENSOR SIGNAL OR OTHER

• Access the climate control unit PID AMB_TEMP_INTERNAL using the M-MDS.

• Does the AMB_TEMP_INTERNAL PID value indicate the actual cabin temperature of the vehicle?

|

Yes

|

Go to Step 9.

|

|

No

|

Go to the next step.

|

|

7

|

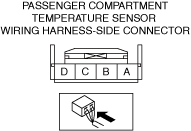

INSPECT PASSENGER COMPARTMENT TEMPERATURE SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

8

|

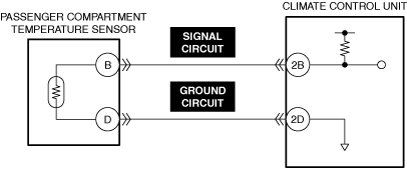

INSPECT PASSENGER COMPARTMENT TEMPERATURE SENSOR SIGNAL CIRCUIT AND GROUND CIRCUIT FOR SHORT CIRCUIT AND OPEN CIRCUIT

• Inspect the applicable circuit for a short circuit and open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

9

|

DETERMINE IF MALFUNCTION CAUSE IS SOLAR RADIATION SENSOR SIGNAL OR OTHER

• Access the dash-electrical supply unit PID SOLAR_SEN_L and SOLAR_SEN_R using the M-MDS.

• Does the SOLAR_SEN_L and SOLAR_SEN_R PID value display according to the solar radiation condition?

|

Yes

|

Go to Step 11.

|

|

No

|

Go to the next step.

|

|

10

|

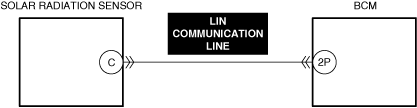

INSPECT SOLAR RADIATION SENSOR LIN COMMUNICATION LINE FOR SHORT CIRCUIT AND OPEN CIRCUIT

• Inspect the applicable circuit for a short circuit and open circuit.

• Is the circuit normal?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, replace the solar radiation sensor and perform the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

11

|

INSPECT DRIVER-SIDE AIR MIX ACTUATOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Inspect the air mix door and linkage for sticking.

If there is no malfunction:

• Go to the next step.

If there is any malfunction:

• Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

12

|

INSPECT A/C RELAY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

13

|

DETERMINE IF MALFUNCTION CAUSE IS A/C RELAY CONTROL SIGNAL OR MAGNETIC CLUTCH

• Start the engine and idle it.

• Access the PCM PID A/C_RLY using the M-MDS.

• Turn the A/C_RLY PID to TRUE (on) from FALSE (off) using the M-MDS simulation function.

• Measure the voltage at the magnetic clutch terminal A (wiring harness-side).

• Is the voltage 10.5 V or more?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 15.

|

|

14

|

INSPECT IF MALFUNCTION CAUSE IS MAGNETIC CLUTCH OR MAGNETIC CLUTCH GROUND CIRCUIT

• Switch the ignition off.

• Disconnect the magnetic clutch connector.

• Inspect for continuity between magnetic clutch terminal A (part-side) and body ground.

• Is there continuity?

|

Yes

|

Inspect the magnetic clutch.

If there is any malfunction:

• Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

No

|

Inspect the A/C compressor. (poor contact to ground)

If there is any malfunction:

• Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

15

|

INSPECT REFRIGERANT PRESSURE SENSOR No.1 AND No.2 FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

The system is normal. (Effect is due to a possible change in the vehicle environment while the engine is stopped (change in solar radiation).)

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF MALFUNCTION IS CAUSED BY NOT PERFORMING PCM REPROGRAMMING

• Verify repair information and verify that there is a new calibration in the PCM.

• Is there a new calibration in the PCM?

|

Yes

|

Perform the PCM reprogramming and verify if the malfunction symptom was corrected.

• If the malfunction recurs, replace the PCM.

|

|

No

|

Replace the PCM.

|