|

CLUTCH COVER INSPECTION [J65M-R]

id0510008008a2

1. Disconnect the negative battery cable.

2. Remove the following parts:

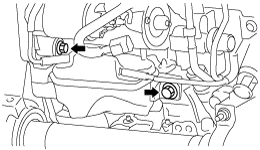

3. Cut off the vacuum chamber installation bolt and set the vacuum chamber aside so that it does not interfere with the servicing.

am3zzw00005914

|

4. Remove the starter.

5. Drain the transaxle oil into a suitable container. (See TRANSAXLE OIL REPLACEMENT [J65M-R].)

6. Remove the manual transaxle. (See MANUAL TRANSAXLE REMOVAL/INSTALLATION [J65M-R].)

7. Remove the clutch cover. (See CLUTCH UNIT REMOVAL/INSTALLATION [J65M-R].)

8. Measure the wear of the diaphragm spring fingers.

am3zzw00006216

|

9. Measure the flatness of the pressure plate with a straight edge and a feeler gauge.

am3zzw00006217

|

10. When checking the diaphragm spring fingers, mount a dial gauge on the cylinder block.

am3zzw00006218

|

11. Rotate the flywheel and check for misaligned diaphragm spring fingers.

12. Install in the reverse order of removal.

13. Add the specified amount of specified transaxle oil. (See TRANSAXLE OIL REPLACEMENT [J65M-R].)

14. Perform the clutch fluid line air bleeding. (See CLUTCH FLUID AIR BLEEDING/REPLACEMENT.)