|

ENGINE REMOVAL/INSTALLATION [MZR 1.6]

id0110f6800400

1. Disconnect the negative battery cable. (See NEGATIVE BATTERY CABLE DISCONNECTION/CONNECTION [MZR 1.6].)

2. Remove the air cleaner, air hose and fresh air duct as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZR 1.6].)

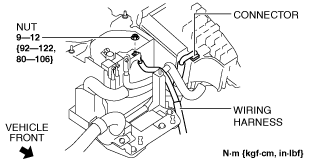

3. Remove the nut and connector shown in the figure, and set the wiring harness aside.

am3zzw00016320

|

4. Remove the battery tray and PCM component. (See BATTERY REMOVAL/INSTALLATION [MZR 1.6].)

5. Remove the front under cover No.1 and No.2. (See FRONT UNDER COVER No.1 REMOVAL/INSTALLATION.) (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

6. Remove the front splash shield No.1. (See SPLASH SHIELD REMOVAL/INSTALLATION.)

7. Drain the engine coolant. (See ENGINE COOLANT REPLACEMENT [MZR 1.6].)

8. Drain the transaxle oil (MTX) or ATF (ATX). (See MANUAL TRANSAXLE OIL REPLACEMENT [F35M-R].) (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FN4A-EL].)

9. Remove the front wheels and tires. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

10. Disconnect the selector cable. (ATX) (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [FN4A-EL].)

11. Disconnect the control cable. (MTX) (See MANUAL TRANSAXLE REMOVAL/INSTALLATION [F35M-R].)

12. Remove the clutch release cylinder with the pipe still connected. (MTX) (See CLUTCH RELEASE CYLINDER REMOVAL/INSTALLATION [F35M-R].)

13. Disconnect the vacuum hose. (See VACUUM HOSE REMOVAL/INSTALLATION.)

14. Disconnect evaporative hose from the engine side.

15. Disconnect the fuel hose from the engine side. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION [MZR 1.6].)

16. Disconnect the upper radiator hose. (See COOLING FAN MOTOR REMOVAL/INSTALLATION [MZR 1.6].)

17. Disconnect the heater hose. (See A/C UNIT REMOVAL/INSTALLATION.)

18. Disconnect the lower radiator hose. (See RADIATOR REMOVAL/INSTALLATION [MZR 1.6].)

19. Remove the drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [MZR 1.6].)

20. Remove the A/C compressor with the cooler hose still connected and secure it using wire or rope so that it is out of the way. (with A/C) (See A/C COMPRESSOR REMOVAL/INSTALLATION [MZR 1.6].)

21. Remove the presilencer installation nuts (exhaust manifold side) and secure the presilencer using wire or rope so that it is out of the way. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [MZR 1.6].)

22. Disconnect the front drive shaft from the transaxle side and set the drive shaft aside. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

23. Remove the bolt and clips, and set the ground cable aside.

RH

am3zzw00016321

|

LH

am3zzw00016322

|

24. Remove in the order indicated in the table.

25. Install in the reverse order of removal.

26. Refill the transaxle oil (MTX) or ATF (ATX). (See MANUAL TRANSAXLE OIL REPLACEMENT [F35M-R].) (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FN4A-EL].)

27. Refill the engine coolant. (See ENGINE COOLANT REPLACEMENT [MZR 1.6].)

28. Start the engine, and inspect and adjust the following:

am3zzw00016323

|

|

1

|

Deadweight (ATX)

|

|

2

|

Bracket plate

|

|

3

|

No.1 engine mount rubber, front crossmember component

|

|

4

|

No.1 engine mount bracket

|

|

5

|

No.4 engine mount bracket

|

|

6

|

No.3 engine mount

|

|

7

|

Engine, transaxle

|

No.1 Engine Mount Rubber, Front Crossmember Component Removal Note

1. Loosen the bolts shown in the figure.

am3zzw00016324

|

2. Remove the No.1 engine mount rubber and the front crossmember component as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [MZR 1.6].)

No.3 Engine Mount, No.4 Engine Mount Bracket Removal Note

1. Secure the engine and transaxle using a commercially available engine lifter.

am3zzw00006876

|

2. Remove the No.4 engine mount bracket.

3. Remove the No.3 engine mount.

Engine Mount Installation Note

1. Tighten the stud bolts of the engine front cover.

am3zzw00014884

|

2. Tighten the stud bolts of the No.4 engine mount support bracket.

am3zzw00016325

|

3. Secure the engine and transaxle using a commercially available engine lifter.

am3zzw00006876

|

4. Temporarily tighten the No.3 engine mount installation bolts and nuts using the following procedure:

ac5uuw00003037

|

ac5uuw00003038

|

5. Temporarily tighten the No.4 engine mount bracket installation bolt and nuts using the following procedure:

am3zzw00016326

|

am3zzw00016327

|

6. Install the No.1 engine mount rubber and the front crossmember component as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [MZR 1.6].)

7. Install the following parts, and temporarily tighten the bolts shown in the figure.

am3zzw00016328

|

am3zzw00016329

|

8. Tighten the No.1 engine mount bracket and bracket plate installation bolts in the order shown in the figure.

MTX

aaxjjw00018261

|

ATX

aaxjjw00018262

|

9. Tighten the No.3 engine mount installation bolts and nuts in the order shown in the figure.

am3zzw00016095

|

Tightening torque

|

Installation position |

Tightening torque |

|---|---|

|

1

|

76—95 N·m {7.8—9.6 kgf·m, 57—70 ft·lbf}

|

|

2

|

55—65 N·m {5.7—6.6 kgf·m, 41—47 ft·lbf}

|

|

3

|

49—65 N·m {5.0—6.6 kgf·m, 37—47 ft·lbf}

|

10. Tighten the No.4 engine mount bracket installation bolt and nuts in the order shown in the figure.

am3zzw00016096

|

Tightening torque

|

No. |

Tightening torque |

|---|---|

|

1, 2, 3

|

92—116 N·m {9.4—11 kgf·m, 68—85 ft·lbf}

|

|

4

|

81—99 N·m {8.3—10 kgf·m, 60—73 ft·lbf}

|

11. Tighten the bolt shown in the figure.

MTX

am3zzw00016330

|

ATX

am3zzw00016331

|

12. Tighten the No.1 engine mount rubber installation bolts shown in the figure.

am3zzw00016332

|

Tightening torque

|

Installation position |

Tightening torque |

|---|---|

|

No.1 engine mount bracket side

|

140—163 N·m {15—16 kgf·m, 104—120 ft·lbf}

|

|

Front crossmember side

|

130—164 N·m {14—16 kgf·m, 96—120 ft·lbf}

|